Well Control on Delfi

Enhanced, cloud-based multiphase well control simulations

Discover a cloud-based solution that facilitates multiphase well control simulations—Well Control on Delfi™

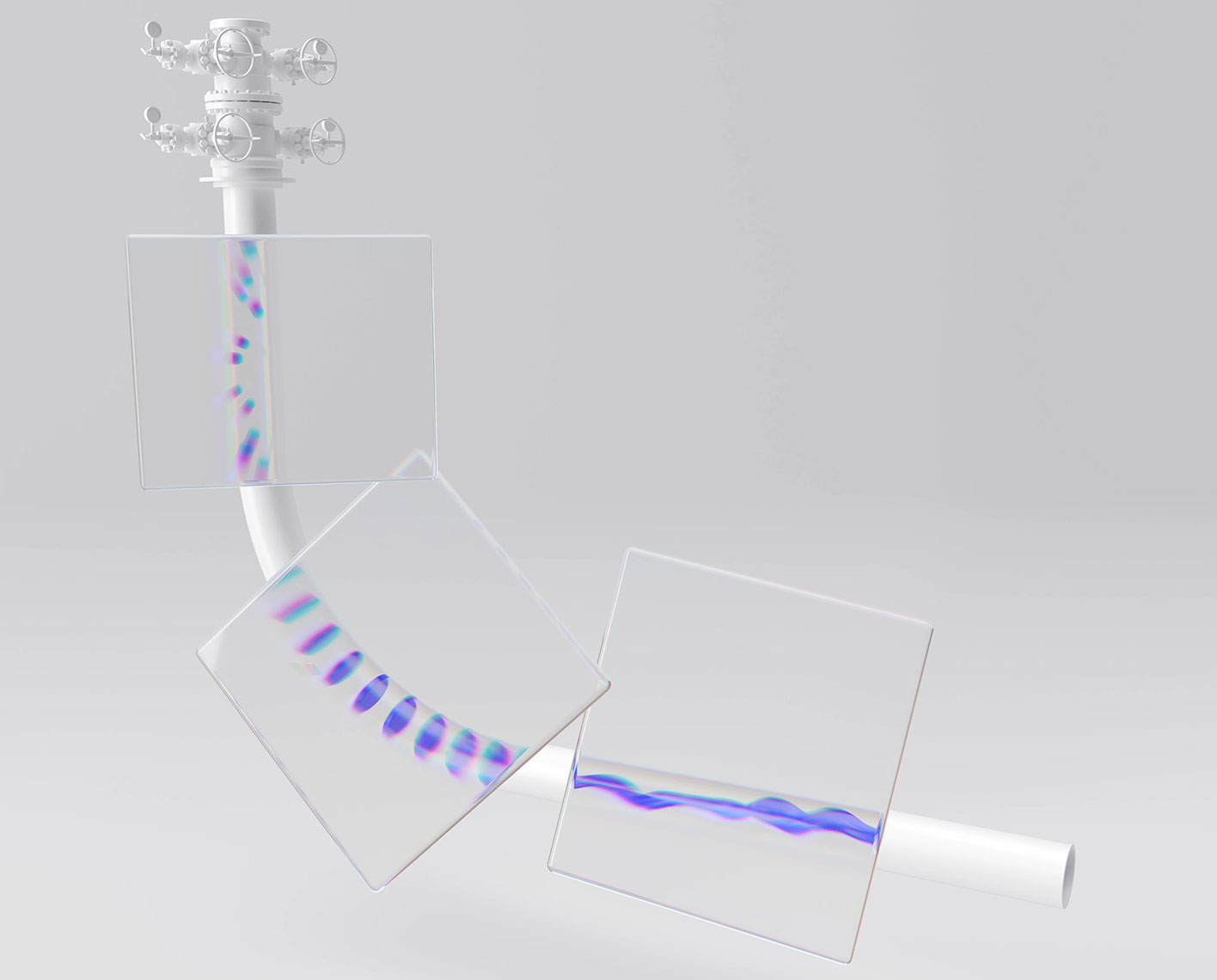

Successfully drilling challenging wells requires an in-depth understanding of the hydraulics during all phases of the operation. The drilling process is highly dynamic and complicated to model; thus, much of the dynamics have traditionally been neglected. However, with diminishing operational margins, the impact of dynamic effects is growing. Coupled with increasing well construction costs, modeling the dynamics becomes essential and strategically important.

Simulations performed in Drillbench dynamic drilling simulation software are key feature to replicate a real drilling operation and provide accuracy not possible with simpler steady-state models. Drillbench software provides a user-friendly tool that targets all drilling engineers involved in challenging wells. The software is built around the well-control workflow, covering pressure control, well control, and blowout control.

Drillbench 2025.1 introduces mud-gas separator (MGS) modeling, using the separator functionality from the Olga™ dynamic multiphase flow simulatorsimulator, to simulate the behavior of key rig safety equipment during well control events. It enables users to configure a vertical separator tank, define flare and mud outlet lines for gas venting and liquid discharge, and calculate frictional pressure losses and separator internal pressure. The module provides real-time estimation of mud level, automatic detection of liquid seal breaches, and level regulation logic to prevent instabilities. Users receive notifications for underfill conditions when the mud outlet is closed due to low liquid levels.

Kick intensity in Drillbench 2025.1 functions as it did in Drillbench 2022.1, allowing users to specify additional kick intensity for the reservoir during interactive mode. Users can enable and define kick intensity through a checkbox and field, and adjust it during simulation by pausing, updating, and restarting the simulation. This feature permits changes in kick intensity to dynamically affect reservoir pressure.

The reservoir model in Drillbench 2025.1 maintains the same functionality as in Drillbench 2022.1, enabling users to switch between linear productivity index (PI) and a reservoir model using a radio button to define flow characteristics. When selecting the reservoir model, users must input permeability if the influx phase is gas, and both permeability and oil volume factor if the influx phase is oil, with the default oil volume factor set to 1.0.

The Olga simulator has been upgraded to the current version, Olga 2025.1.

Enhance the simulation by adding back pressure as a managed pressure drilling (MPD) option In Drillbench 2025.1, back pressure in an MPD setting and is represented as annulus pressure at the surface within the simulation mode. Users can adjust this back pressure during interactive simulations, through the simulation control interface, enabling them to increase annulus pressure to achieve an over-balanced well and stop influx. Additionally, the back pressure can be modified in the run configuration table, providing flexibility in managing drilling conditions.

Drillbench software training courses address the unique need of each learner, our courses, delivered by world-class experts, teach learners how to deal with real-life scenarios and solve genuine problems.

Proven dynamic modeling for primary well control to maintain wellbore pressures within the operating window for all drilling operation

Advanced well control engineering for planning and operations

Proven tool for dynamic kill modeling and relief well planning—harnessing the power of the OLGA engine for tertiary well control

World leading software built to solve your challenges.

See the latest digital articles, webinars, podcasts, blogs and tech talks.

Access a variety of technical assisted support services and submit support requests online.