Drillbench XD

Dynamic drilling simulation software

Discover a cloud-based solution that facilitates multiphase well control simulations—Well Control on Delfi™

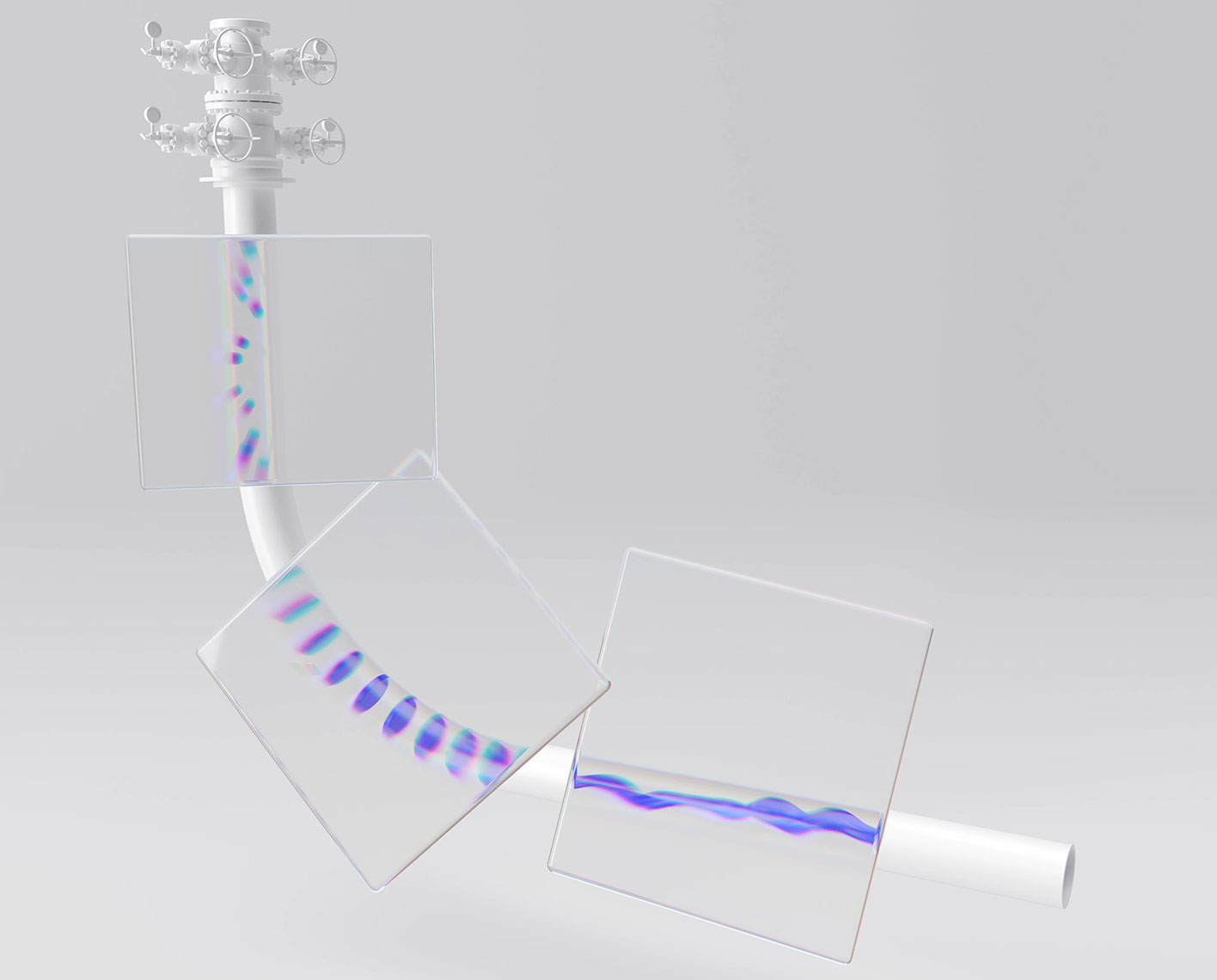

Drillbench dynamic hydraulics is an advanced hydraulics and temperature simulator and provides valuable insight, on how the drilling operation is impacting the wellbore pressure and available margins. This is based on dynamic simulations of pressure and temperature conditions. These can be used to optimize design and operations, to avoid drilling problems and help the drilling crew avoid potential drilling hazards.

A realistic dynamic model is required to understand the transient behaviour of the well and is valuable for well planning, training, and operational support. It is well known that in advanced wells (e.g., HPHT wells, deep water wells, extended reach wells, wells in depleted reservoirs, and wells in areas with gas or water injection), the margins between pore pressure and fracture pressure may be small. In the future, the drilling targets will be even more difficult.

Drillbench dynamic hydraulics module in Drillbench software can be used to simplify this planning process and help the drilling engineer make better decisions.

Software training courses address the unique need of each learner, our courses, delivered by world-class experts, teach learners how to deal with real-life scenarios and solve genuine problems.

World leading software built to solve your challenges.

See the latest digital articles, webinars, podcasts, blogs and tech talks.

Access a variety of technical assisted support services and submit support requests online.