NeoLink

Real-time downhole wired drillpipe control

Accelerate surface and downhole interactions to ensure a more sustainable well construction operation.

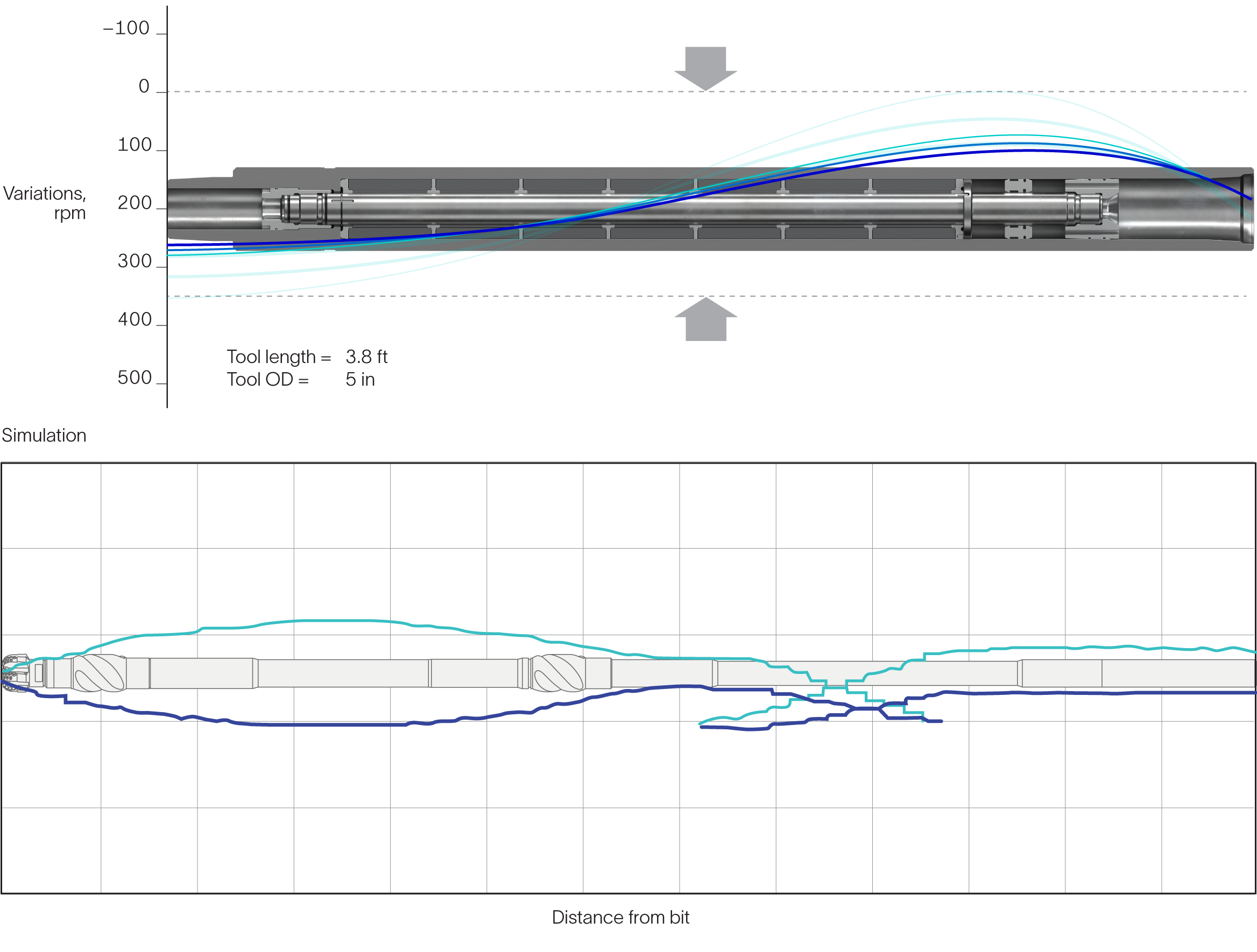

Shock and vibration, specifically high-frequency torsional oscillation (HFTO), are the leading causes of downhole tool failure, often resulting in cracked drill collars and broken measurement and electronic components. The Suppressor dampening tool absorbs and reduces high-frequency torsional vibration downhole. This minimizes the risk of BHA tool failure and enables PDC cutters to stay sharp for faster, longer drilling. By optimizing drilling efficiency in challenging environments and improving BHA tool reliability, it eliminates trips and improves rate of penetration (ROP) and footage.

The Suppressor dampening tool is a proven solution specifically designed for drilling environments that experience excessive vibrations. It helps prevent premature tool failures and optimizes operations with RSS-powered BHAs, while also reducing high cutter damage in challenging formations, minimizing the need for premature hole exits. The tool also ensures reliable performance in high-temperature environments, including geothermal applications.

Nonmagnetic assembly prevents BHA interference.

Metal-to-metal seal handles aggressive drilling fluids and severe downhole conditions.

Suppressor dampening tool supports up to 350 rpm to deliver higher ROP and minimize stick/slip.

The Suppressor dampening tool diminishes HFTO by over 60% compared with offset wells without damping. Its simple mechanical design and metal-to-metal sealing not only ensure reliability in high-temperature wells up to 500 degF [260 degC] but also reduces the risk of downhole tool failure. This dependable tool effectively minimizes the potential for unplanned trips caused by excessive shock and vibration in challenging hard rock formations. Additionally, it enhances drilling efficiency by enabling increased footage due to efficient energy transfer. The nonmagnetic assembly prevents BHA interference, and its compact length does not limit directional control.