Suppressor flex dampening tool

Eliminates the need for additional tools and connections within the BHA

High-frequency torsional dampening flex sub designed to improve efficiency without impacting BHA design.

The NeoSteer CL™ curve and lateral at-bit steerable system (ABSS) is purpose-built for efficiently navigating both the curve and lateral in a single run, outperforming traditional methods that require multiple trips. It excels in achieving rapid build rates, boosting on-bottom drilling speed, and extending lateral lengths. In scenarios where the vertical, curve, and lateral sections are the same hole sizes, the NeoSteer CL system reduces nonproductive time by removing the need to switch out the bottomhole assembly (BHA) for each section while reducing CO2 emissions on every project.

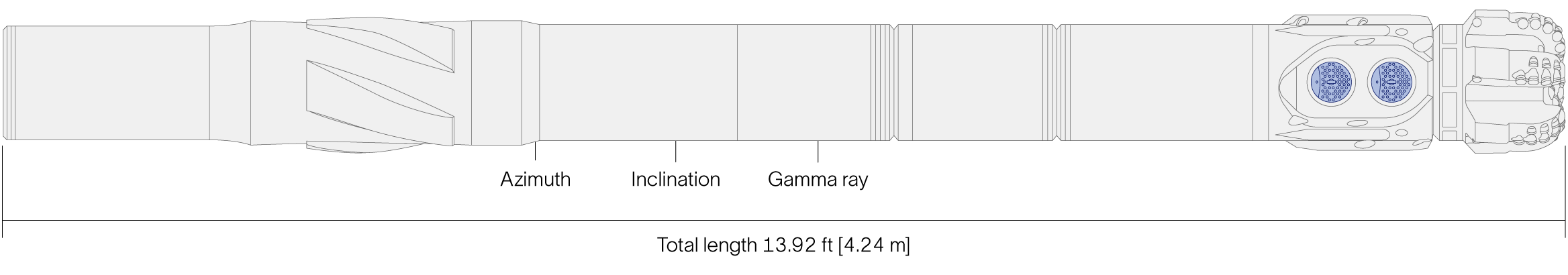

The NeoSteer CL system provides six-axis continuous inclination and azimuth measurements alongside automatic trajectory control, ensuring precise well placement in shale and unconventional wells. Its multiaxial component facilitates automatic hold inclination and azimuth (HIA) measurements to enhance well positioning accuracy. This, combined with its self-steering capabilities, facilitates smooth tangents with minimized tortuosity. Additionally, near-bit extended-range gamma ray measurements offer extra well positioning data for improved real-time decision making.

The NeoSteer CL system can be configured with an onboard azimuthal image gamma ray cartridge to improve in-zone percentage and enable steering within the reservoir sweet spot. Placed just 6 ft behind the cutting structure, the azimuthal gamma ray cartridge enables the ABSS to detect lithology changes sooner, allowing for immediate steering adjustments.