Wireless Telemetry

Enable real-time data monitoring and tool control for reservoir testing operations.

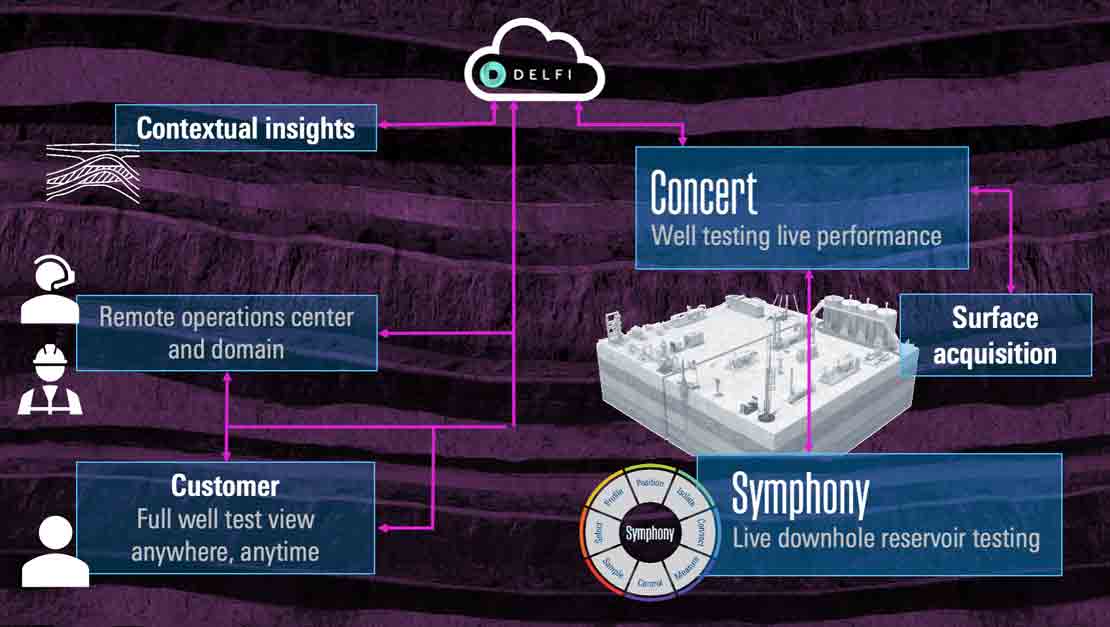

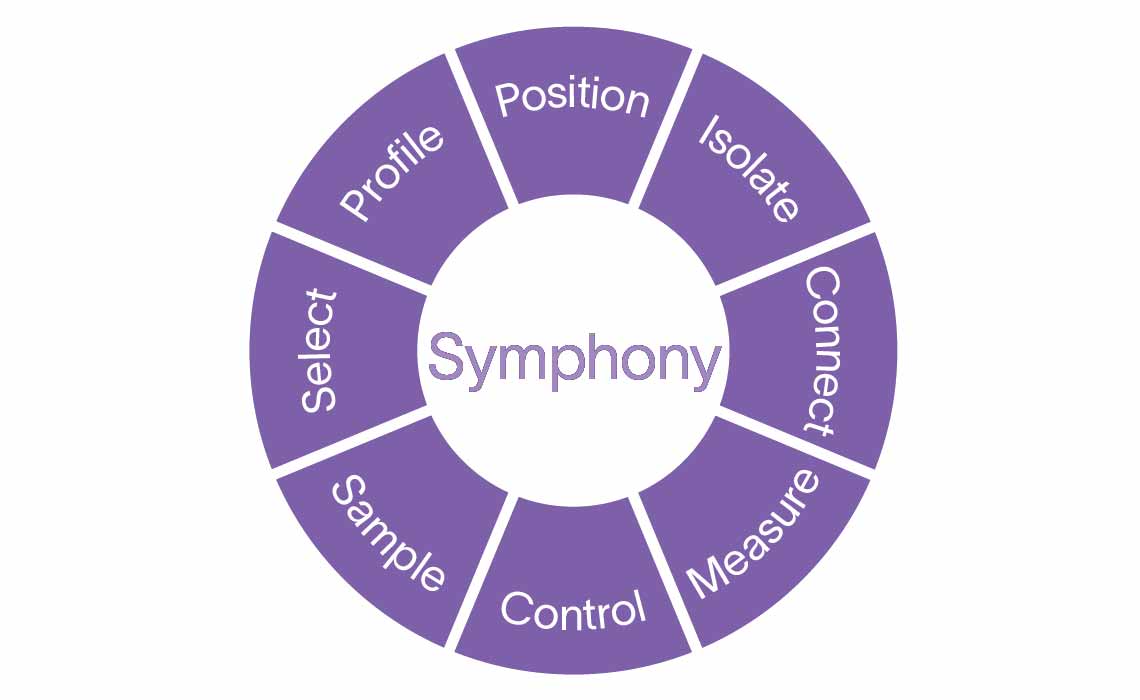

From initial design and simulation to site logistics and the delivery of answers, Symphony testing gives you the collective power of perfectly synchronized wireless reservoir testing—in real time.

We bring together tools, expertise, and global capabilities in perfect harmony to deliver the best customer experience, the best data, and the best value for your complex well tests.

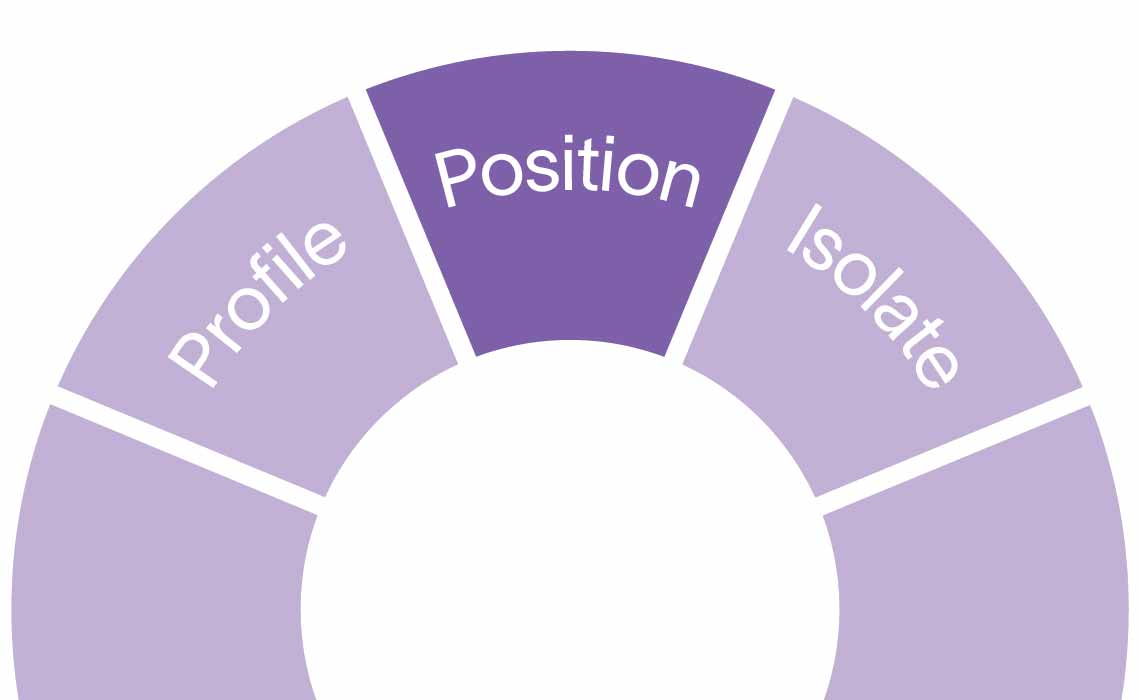

The Position tool wirelessly provides real-time depth correlation to a radioactive marker placed on the casing or to a natural formation gamma ray signature. Continuous real-time gamma ray and pressure measurements are used to position the perforating guns at the target interval with an accuracy of 1 ft [0.3 m]. A photomultiplier tube (PMT) sensor provides fast response and high signal-to-noise ratio for the gamma ray count. This correlation capability eliminates a separate intervention run to obtain a wireline gamma ray and casing correlation log for depth correlation to save rig time, reduce the number of personnel at the wellsite, and enhance safety. Download product sheet.

The Position tool integrated in the Symphony live downhole reservoir testing string provides critical data in real time— eliminating the need for a separate wireline correlation log— to ensure accurate perforating gun positioning in thin pay zones.

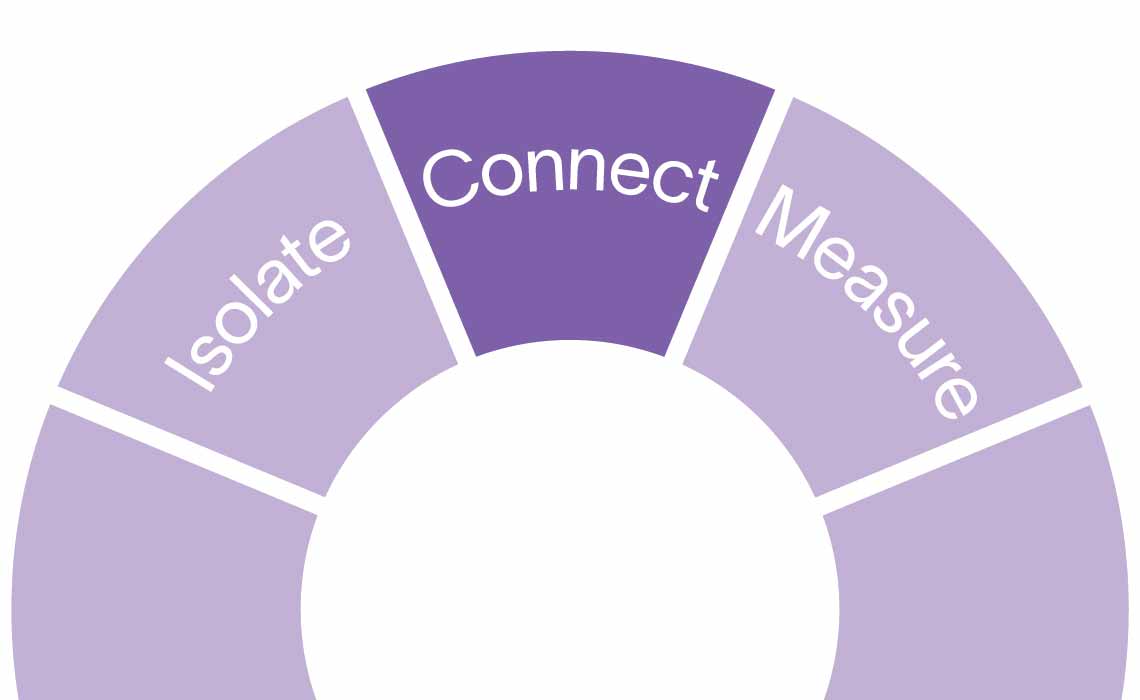

Read Case StudyThe Connect firing head is used to acoustically activate the perforating guns, unlike conventional technology that requires pressure pulse commands generated from high overpressure or mechanical movement to activate. Not only does using acoustic signals enable achieving optimal underbalance conditions before perforating, but it also significantly increases the reliability and safety of perforating operations in combination with the firing head’s field-proven sensors, battery power, microprocessors, and control switches. The system’s flexibility enables incorporating multiple Connect firing heads in a single run and initiating them independently for commingled or selective multizone reservoir testing. Download product sheet.

Measure wireless quartz gauges are seamlessly integrated in the Symphony testing toolstring to provide real-time pressure measurements that enable seeing beyond the near-wellbore area. This wealth of information makes it possible to identify reservoir features in detail and detect seemingly minor pressure fluctuations that can have a significant affect on field development plans. The entire Symphony testing toolstring is monitored by the Measure gauges during testing, and each gauge can be independently interrogated for pressure or temperature data in either real-time or historical mode. Download product sheet.

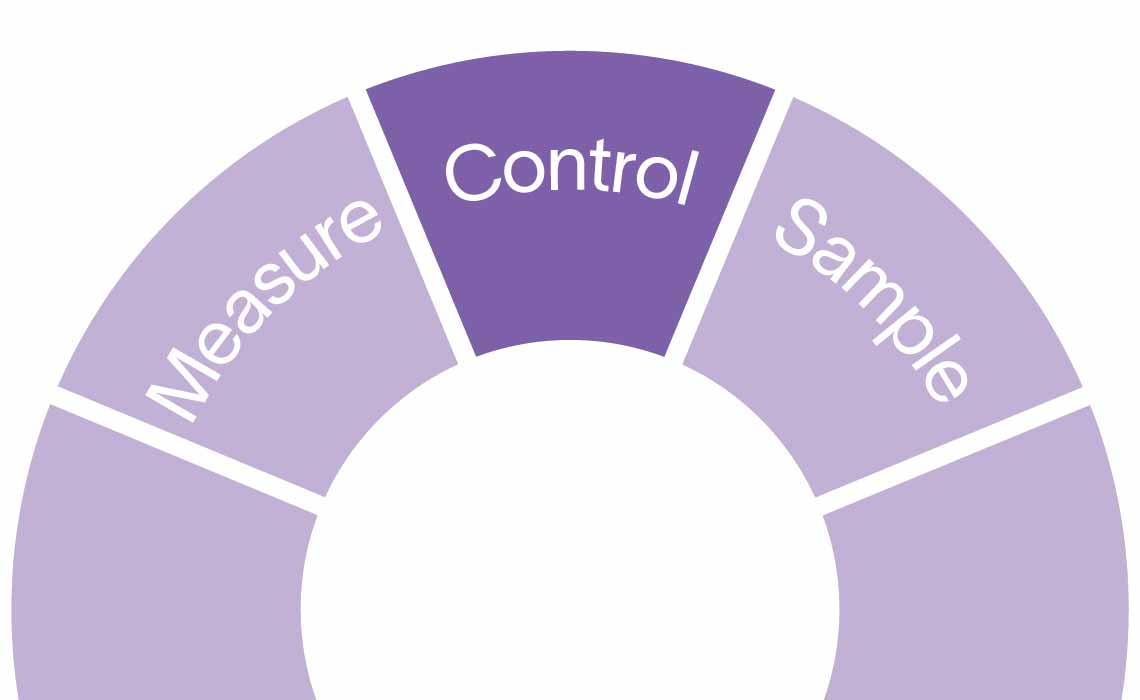

The Control wireless dual valve provides independent dual-valve operation controlled and verified via wireless bidirectional communication. Not only are the circulating and test valves of the Control dual valve operated independently, but multiple Control wireless dual valves can be run in a single Symphony testing string for extended operations or selective multizone testing, with each tool independently operated. The Control dual-valve hydraulic design is insensitive to pressure fluctuations and mud debris, which makes it the ideal tool in previously untestable environments, such as shallow wells or heavy muds, with control maintained going in and coming out of the well at any depth. This rugged operational flexibility is enhanced through redundancy of the wireless communication with contingency capabilities for low-pressure command sequences and mechanical override while eliminating the use of nitrogen for tool operation. Download product sheet.

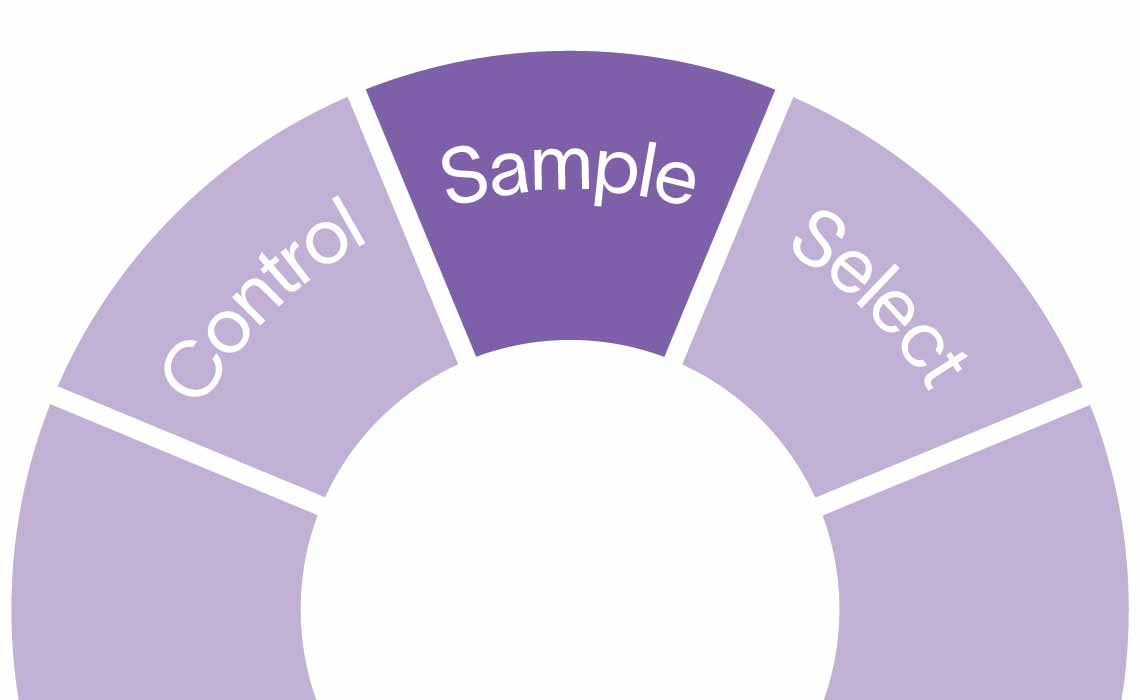

The Sample system obtains contamination-free, representative reservoir fluid samples and can accommodate up to eight INCONEL samplers that can be activated at any time during the flow period. Each sampler has a small independent nitrogen gas charge to ensure that once a sampler self-closes downhole, the individual samples remain in single phase, at or above reservoir pressure. An optional Dursan nonreactive sample chamber ensures that H2S, mercaptans, and trace elements are retained by the Sample system even at low concentration to deliver the most representative reservoir fluid samples.

The Sample wireless selective sampling system replaces pressure-activated rupture disc systems that require a large pressure window, which limits the choice of sample locations and restricts what type of fluid samples can be taken. A contingency pressure backup option ensures operational flexibility and control of sample collection with confidence. Download product sheet.

Wireless sampling system in Symphony testing string provides real-time feedback to activate samplers in optimal location.

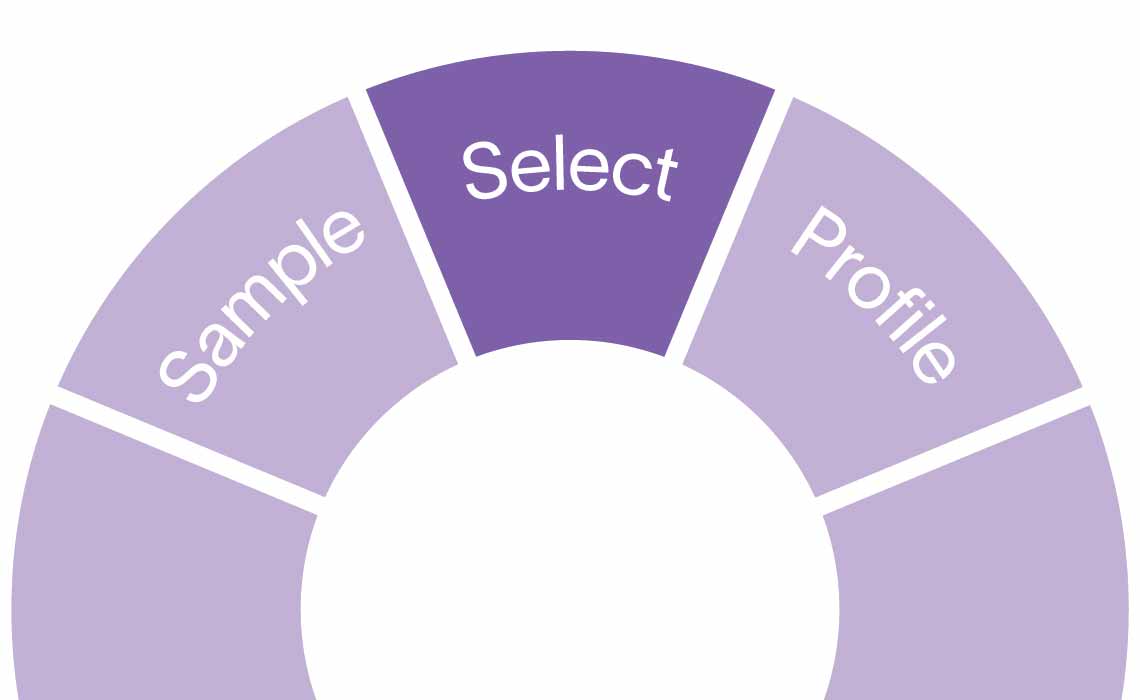

Read Case StudyThe Select wireless isolation valve enables real-time zonal selective flow to allow single-trip selective multizone reservoir testing when it is operated below the Isolate wireless high-integrity reservoir test isolation system in the Symphony testing toolstring. Other typical operations with the Select isolation valve are commingled flow and vertical interference testing. All valve operations are confirmed to surface in real time with measured positive feedback. The sleeve’s robust, highly reliably performance is enhanced through immunity to downhole pressure and temperature fluctuations and elimination of the use of nitrogen. Download product sheet.

We’ll make your job easier by supporting you through the planning and risk mitigation processes, and we take care of the logistics and resource availability headaches so you can focus on getting the results you need.

Our global support team assists by sharing advice and domain expertise, with on-demand response to issues. 24/7 monitoring by testing services specialists is consolidated at our Operations Control Center, supported by on-call technical experts.

With our help, you’ll make a leap in efficiency by developing tests with next-generation approaches that fundamentally reshape the way testing operations are planned and executed.

Symphony testing seamlessly integrates with Concert well testing live performance. Workflows are powered by the DELFI cognitive E&P environment to enable