OmegaX Gyro

Solid-state memory dual-gyroscope

OmegaX Gyro solid-state memory dual-gyroscope measures the Earth's rotation in just 32 seconds.

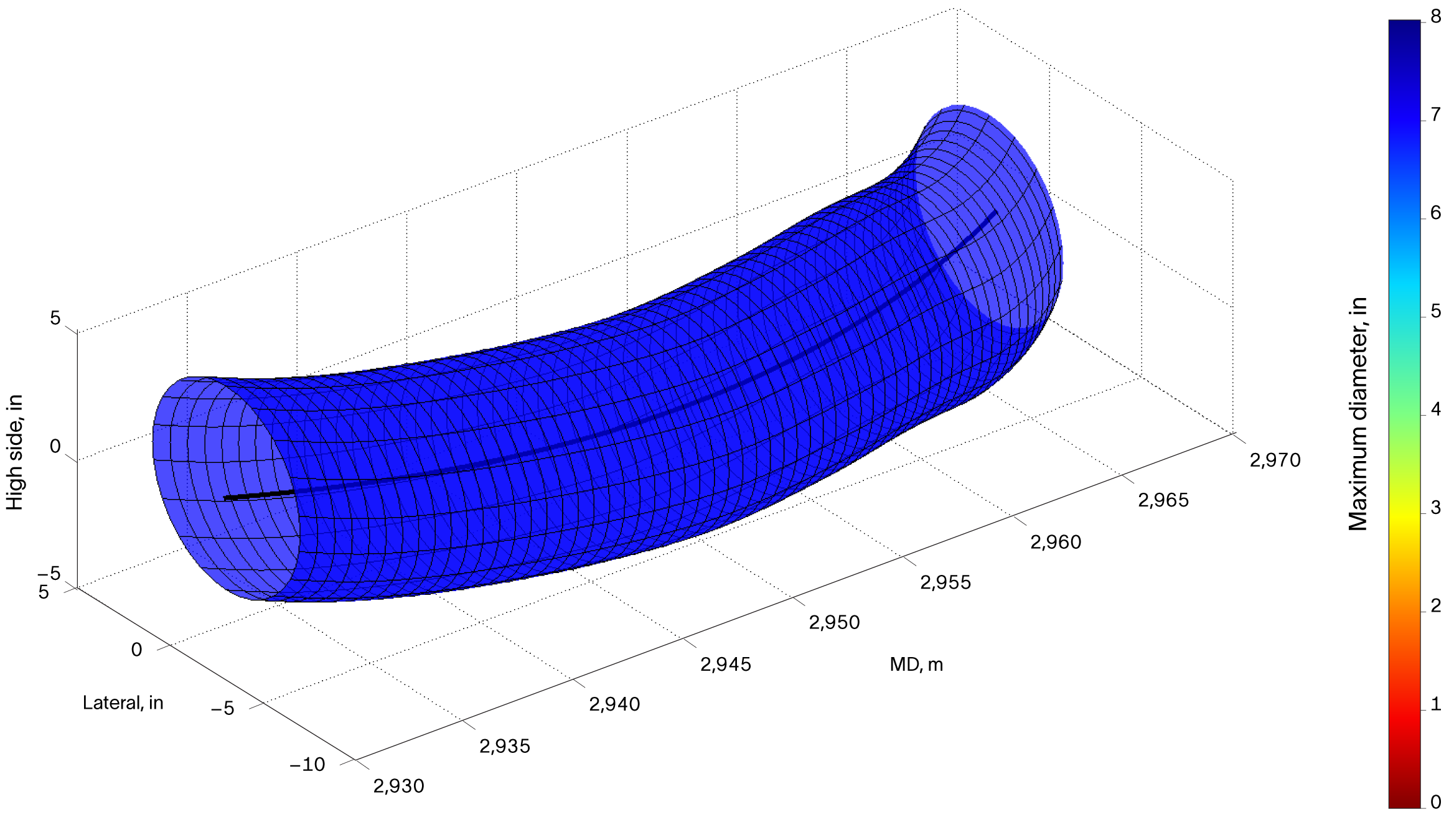

MicroGuide™ high-resolution tortuosity logging enables operators to easily detect anomalies in the wellbore, facilitating smoother drilling, completion, and production operations. With its high-resolution 3D visualization and traditional log formats, it quickly highlights tight intervals or tortuosity issues using high-frequency survey data of the wellbore trajectory. These logs provide comprehensive analyses of tortuosity and obstructions, helping ensure safer drilling operations, smoother casing runs, and optimal placement of artificial lift systems and other equipment, such as electric submersible pumps (ESPs) and rod lift systems. Additionally, interpretations and analysis reports from the MicroGuide log can be tailored to provide specific insights for each wellbore to extend the life of the well and minimize costly workovers.

The MicroGuide high-resolution tortuosity logging can be acquired through two modes. It can operate in continuous gyro surveys conducted through cased hole on wireline, allowing for precise identification of optimal locations for downhole ESPs and other completion equipment, such as packers. These devices are typically installed in the straightest sections of the well to reduce wear and damage, optimizing production and extending their lifespan. The second mode operates in combination with the TruLink™ definitive dynamic survey-while-drilling service, providing real-time insights on borehole quality, identifying tight spots before pulling out of the hole, and generating casing and completion running insights to improve well construction efficiency.

3D visualization of borehole quality

High-resolution tortuosity and obstruction analysis

Future field development improvement by running with existing datasets

Real-time decisions with TruLink™ definitive dynamic survey-while-drilling service