Performance-driven well intervention for production enhancement

A new mindset to optimize production using unique well intervention solutions

How can you optimize production in your brownfield?

When production declines in brownfields, two options to maintain or increase production levels include either drilling infill wells or intervening on already producing wells. As the need to produce more with reduced cost and lower environmental impact is more important than ever, well intervention is key. But nearly 35% of intervention operations don’t meet customer objectives of incremental barrels.*

So how can you ensure the best intervention outcome, every time?

*S. Kitsios; C.A. Shields; S. Vroemen. "Barrel Chasing Through Well Interventions - Can We Get Better At This? " Paper presented at the SPE Offshore Europe Oil and Gas Conference and Exhibition, Aberdeen, UK, September 2013. https://doi.org/10.2118/166598-MS.

A collaborative path to production enhancement

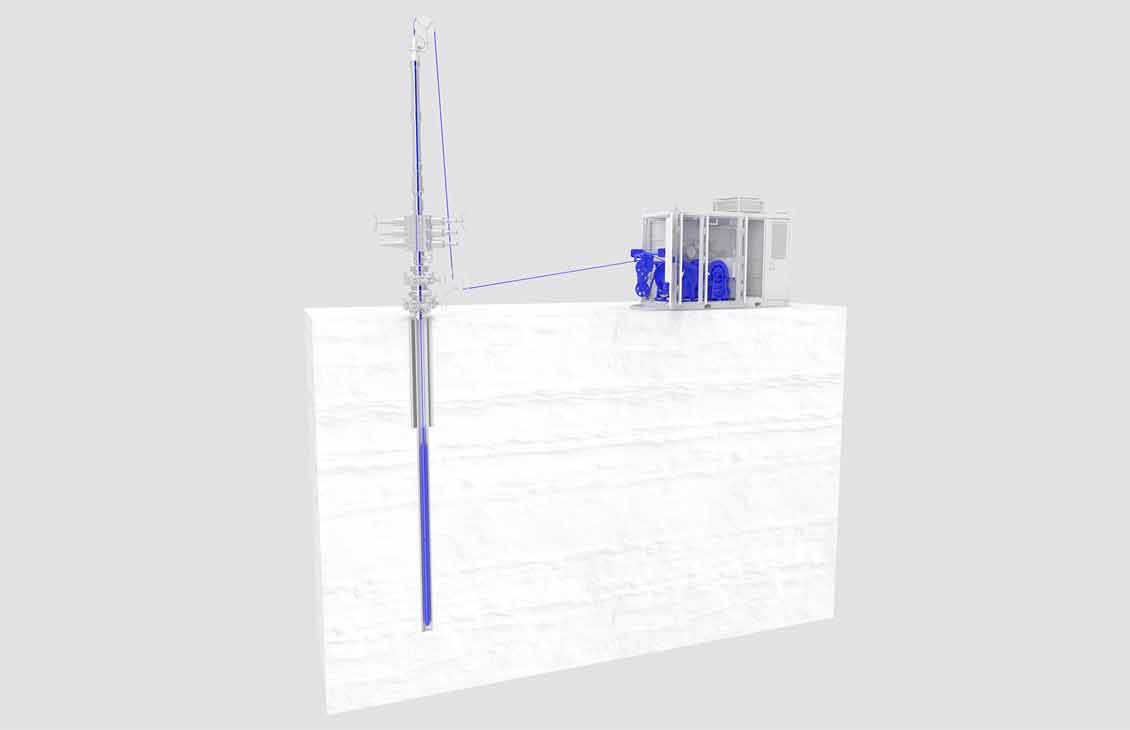

The production enhancement framework from SLB tackles complex production challenges through deep collaboration, domain expertise, a broad technology portfolio, and integrated digital workflows. It’s not a single technology—it’s a strategic approach built on mutual trust and aligned success criteria.

Early engagement

We begin by working closely with operator teams incorporating their knowledge and inputs to assess production constraints, screen candidate wells, and align on success metrics. This ensures shared goals and a clear path to measurable outcomes.

Planning and method selection

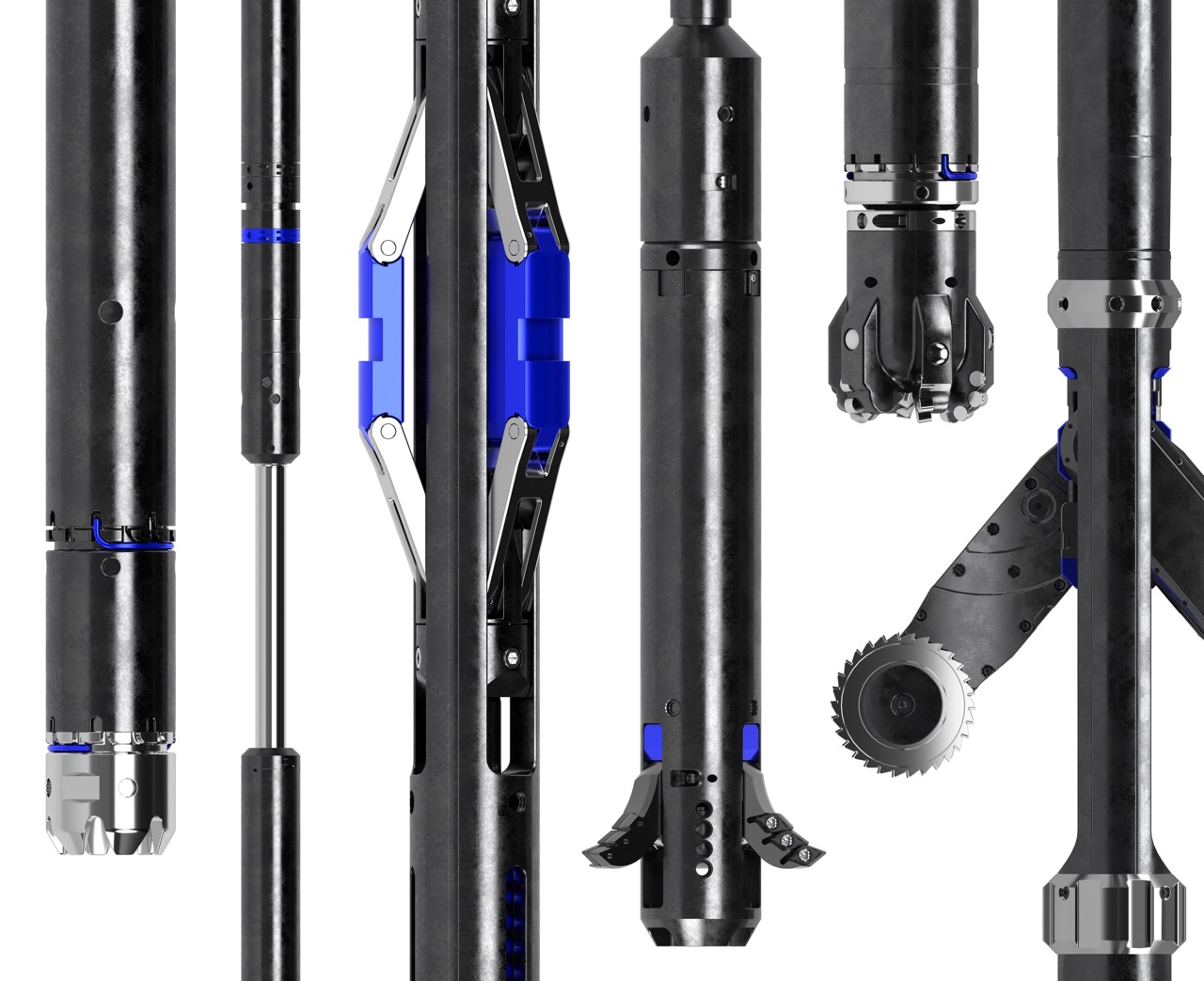

Together, we evaluate all viable intervention options—selecting the most effective solution for each well. This may include SLB technologies, third-party tools, or local solutions—whichever delivers the best performance and value.

Execution with performance focus

Execution is driven by performance metrics defined by the operator—typically incremental barrels, accelerated production, and service efficiency. Every intervention is planned and delivered with these outcomes in mind.

Targeted solutions for production enhancement

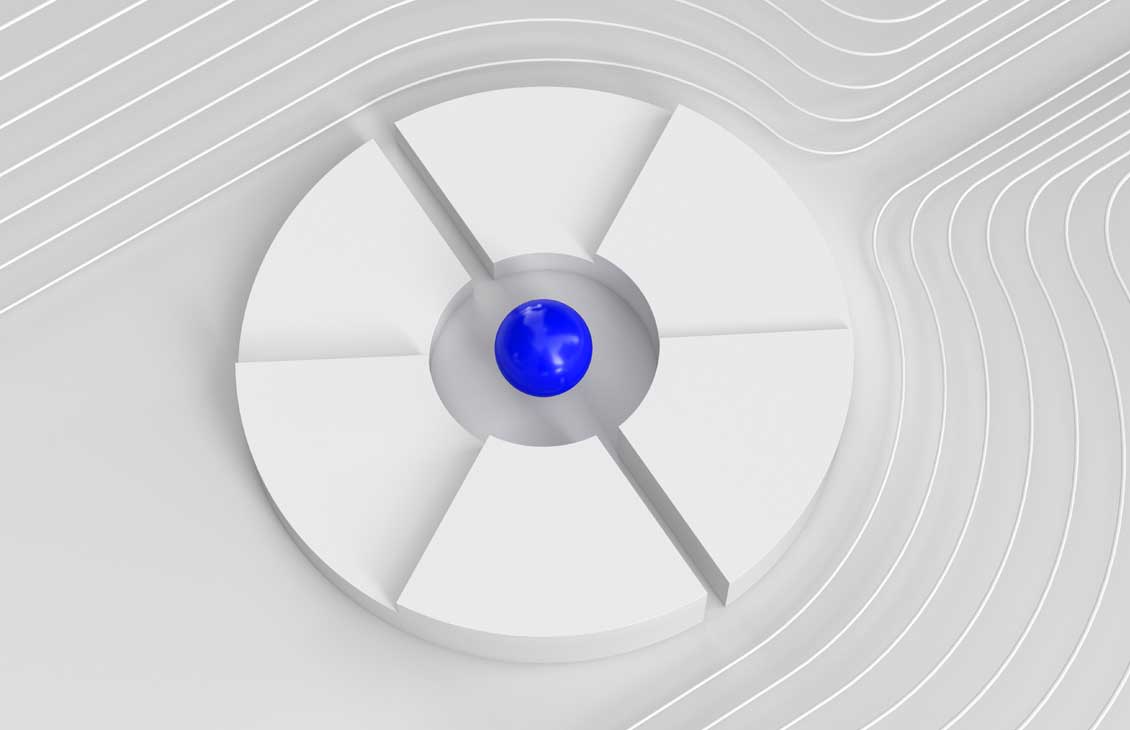

Our production enhancement approach delivers eight targeted solutions, each designed to address specific challenges across the wellbore and reservoir. These solutions are organized by the nature of the production constraint—enabling precise diagnostics, tailored interventions, and measurable outcomes.

Each solution is delivered through a structured workflow supported by advanced diagnostics, proprietary technologies, and proven methodologies. This ensures consistent planning, execution, and performance—driving repeatable success across your asset portfolio.

Well integrity

Extend well life and ensure safe operations by identifying and remediating casing and tubing integrity issues.

Flow assurance

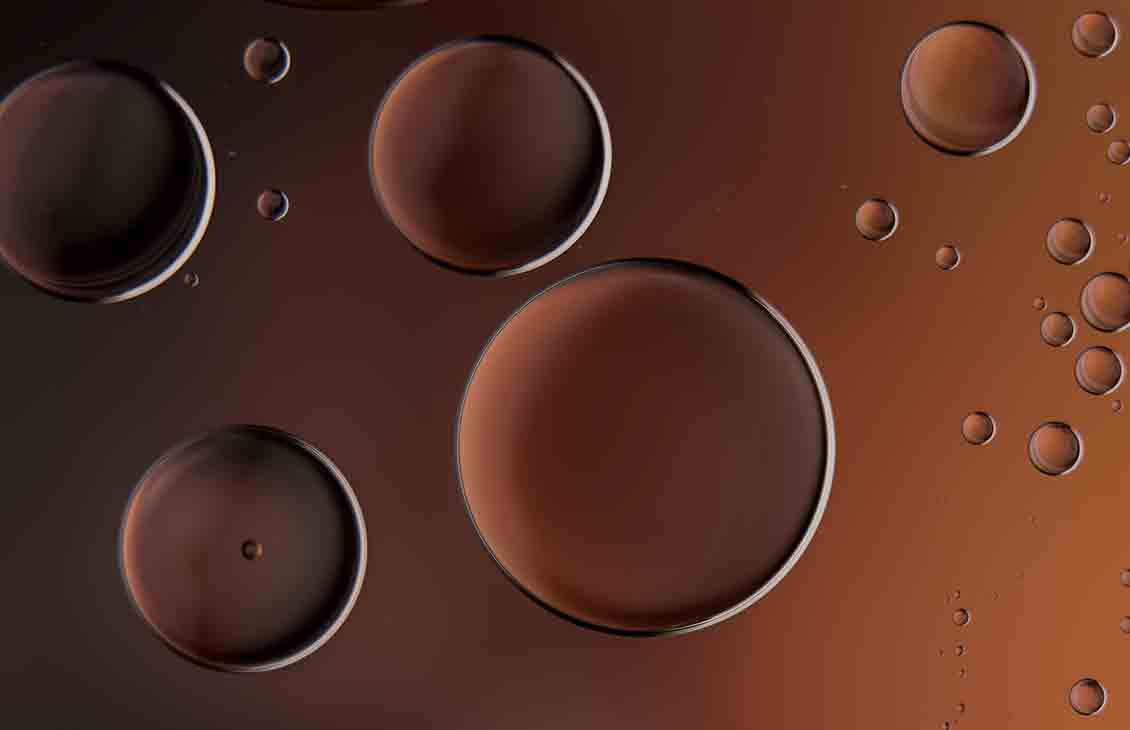

Restore and sustain optimal flow conditions by eliminating blockages and mitigating flow restrictions.

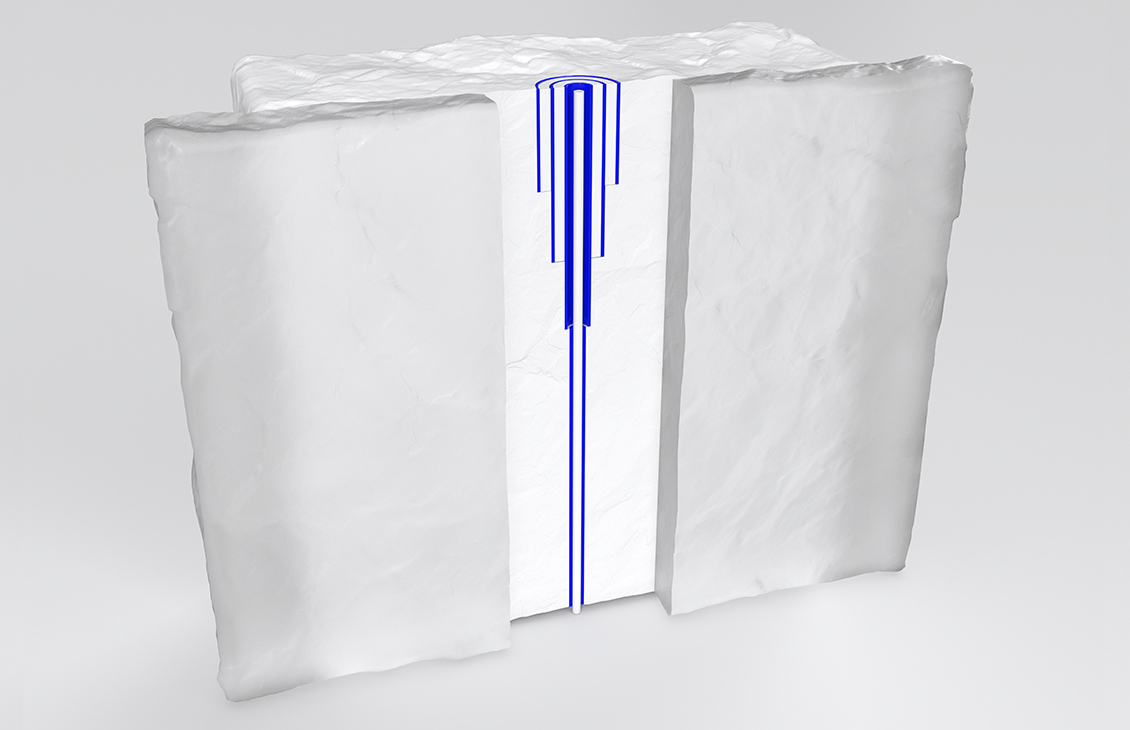

Water and gas shutoff

Reduce operating costs and improve efficiency by controlling unwanted water or gas production.

Production restoration

Recover or stabilize lost production through data-driven diagnostics and focused well interventions.

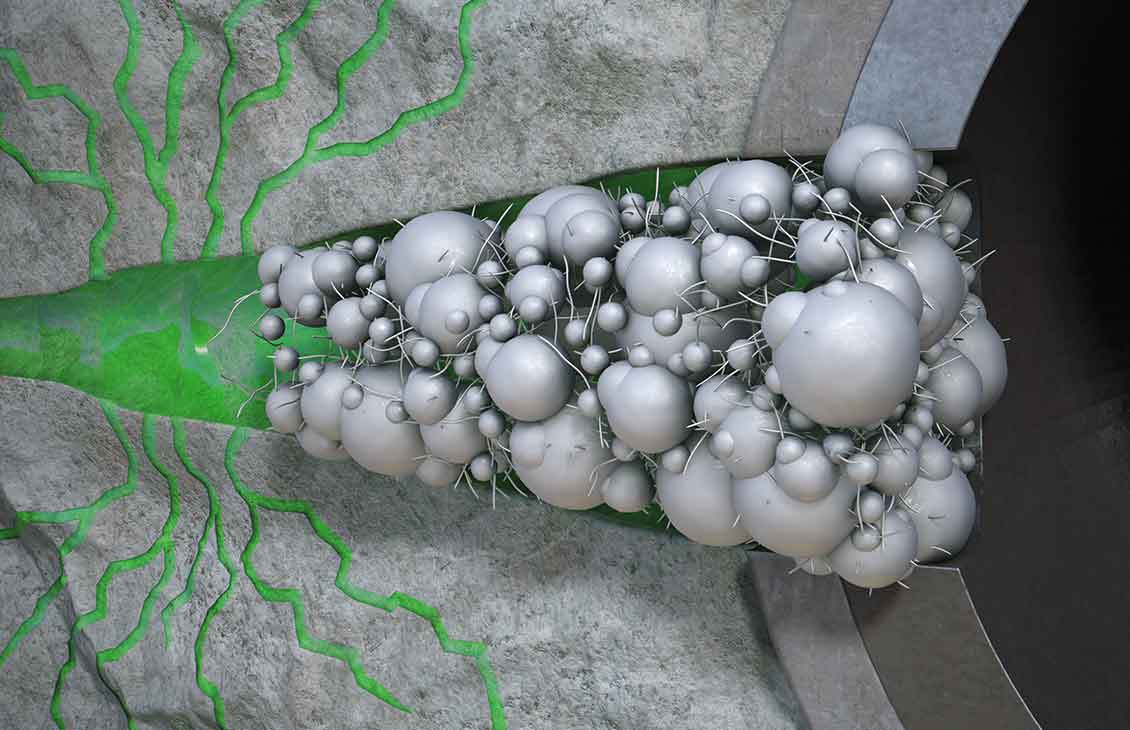

Restimulation

Reinvigorate reservoir contact by building on previous stimulation treatments to unlock additional production.

Sand remediation

Protect equipment and maintain flow continuity by eliminating and managing solids production effectively.

Idle well reactivation

Bring shut-in or non-producing wells back online using selective workovers guided by advanced diagnostics.

Lift optimization

Maximize artificial lift efficiency and sustain production rates through system tuning and performance analysis.

30%

lower cost per barrelCapex

reduction by utilizing existing assetsDigital tools for smarter intervention

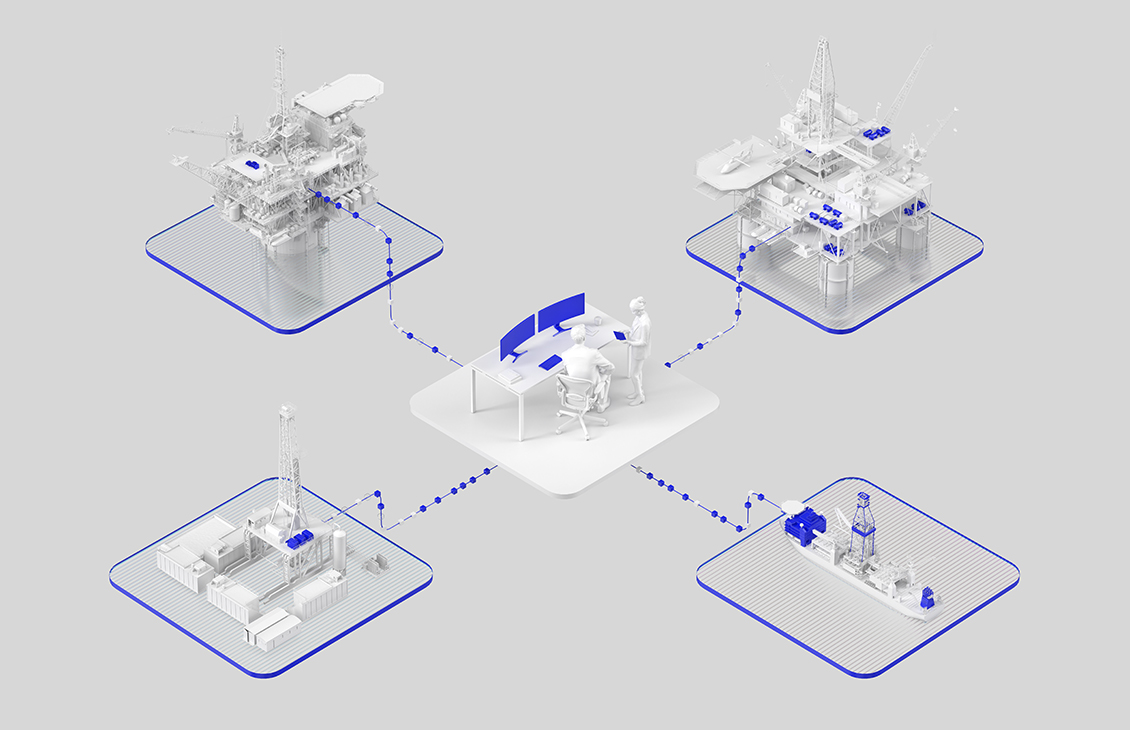

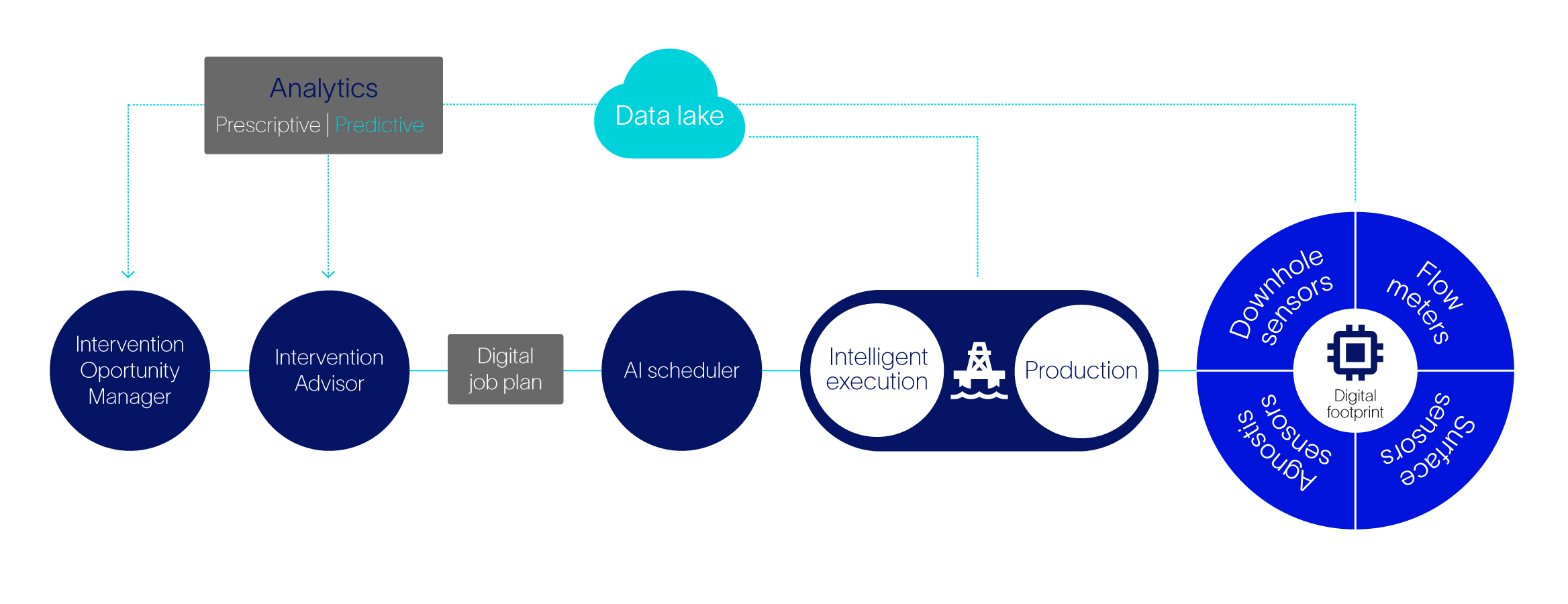

To streamline workflows, reduce complexity, and bring predictability to every stage of the intervention process, we’re building a fully integrated digital ecosystem. This approach enables smarter forecasting of incremental production, tighter cost control, and higher intervention success rates.

Our connected digital workflow links well screening, intervention method selection, planning, and scheduling into a seamless process. This connected approach transforms intervention into a scalable, repeatable, and outcome-focused process.

Candidate identification

AI automatically identifies and ranks the most promising wells using subsurface insights and historical performance data.

Method selection

The optimal intervention method is recommended based on reservoir diagnostics and engineering logic by evaluating cost, duration and chance of success of all available options.

Digital planning and scheduling

Operations are digitally planned with full visibility into risks and outcomes, then scheduled using AI that accounts for real-world constraints—logistics, weather, and resource availability.

Continuous learning loop

A feedback loop powered by AI/ML and prescriptive analytics continuously improves future candidate selection and intervention planning. With hundreds of thousands of jobs ingested into our global data lake, this system learns from every execution to enhance future outcomes.

Intervention Opportunity Manager

Intervention Opportunity Manager (IOM) is a standardized, domain-driven, and fully automated platform for managing well intervention opportunities. It integrates all well data into a unified foundation and continuously refreshes candidate lists and recommended interventions—24/7.

By combining petroleum engineering diagnostics with operator business logic and AI/ML algorithms, IOM delivers consistent, holistic well analysis. It doesn’t replace the workgroup—it empowers it, providing a prioritized shortlist of candidates for deeper evaluation.

Intervention Advisor

Intervention Advisor™ collaborative intervention method selection solution is an AI‑powered planning tool for intervention operations. It enables engineers to:

- Build decision trees to evaluate intervention methods based on cost, success probability, and economics

- Generate high-level intervention plans with built-in contingency options

- Collaborate with reservoir engineers to model pre- and post‑intervention production and estimate gains across scenarios

The platform also outputs workplan recommendations based on estimated duration and quantified success probability—helping teams make informed, confident decisions.

Featured case studies

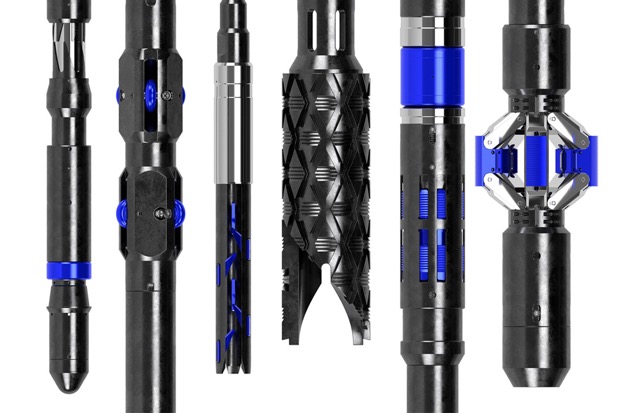

Featured technologies

SLB Solution

Accelerated Time to Market

Let's optimize your production

Partner with us and discover how our production enhancement framework can help you optimize production.