Facility Planner on Delfi

Oil & gas facility scoping, cost estimating, and project planning

Collaboratively analyze and simulate multiple facility concepts.

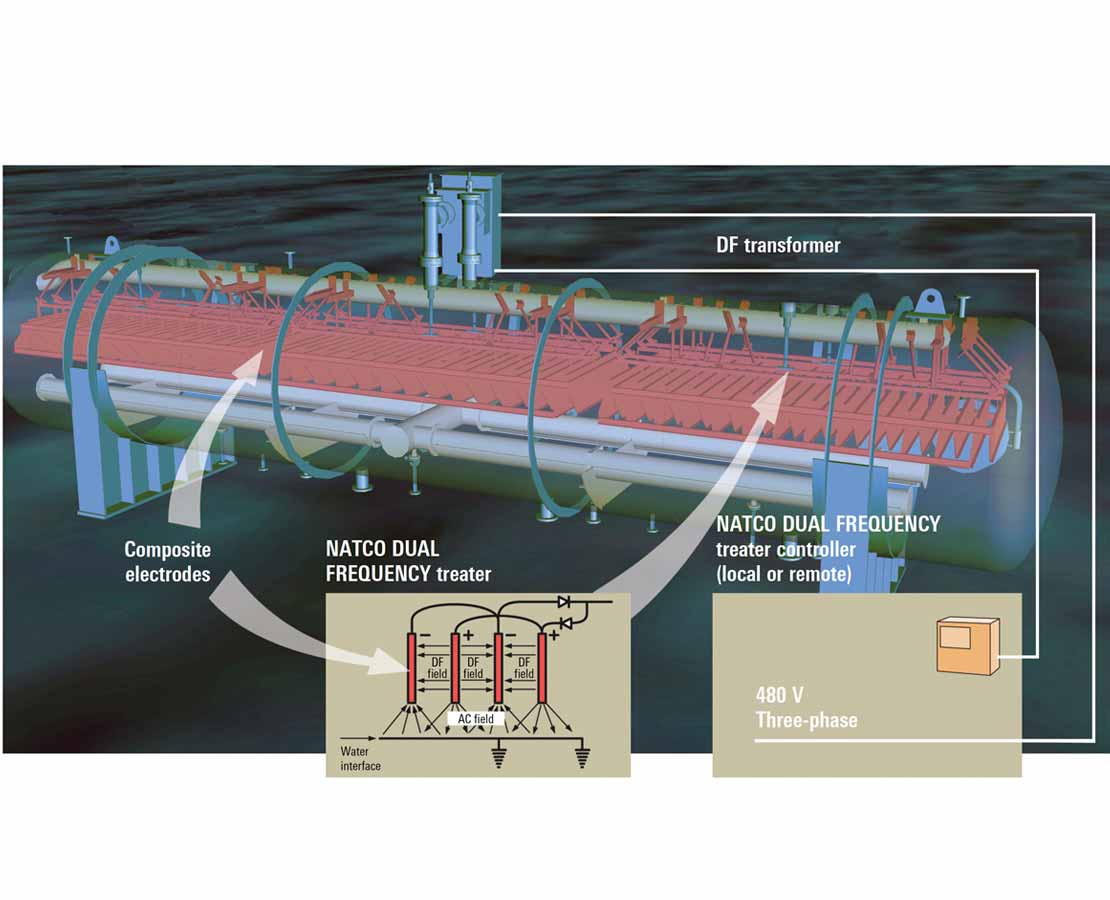

Cost-effective fourth-generation Natco Dual Frequency™ electrostatic treaters have lower annual power requirements than dehydration technologies that use AC-generated electric fields alone or conventional AC-DC technologies. The customizable bimodal AC-DC electrostatic field uses fewer watts per unit volume as it causes small water droplets dispersed within the wet crude to collide, grow, and separate by gravity. Lower electricity consumption leads to a reduction in emissions. In addition, this advanced AC-DC power unit—sometimes called an electrostatic treater transformer—decreases total connected power load and consequently, the heavy-duty high-voltage electrical infrastructure for power generation, power delivery on site, or both.

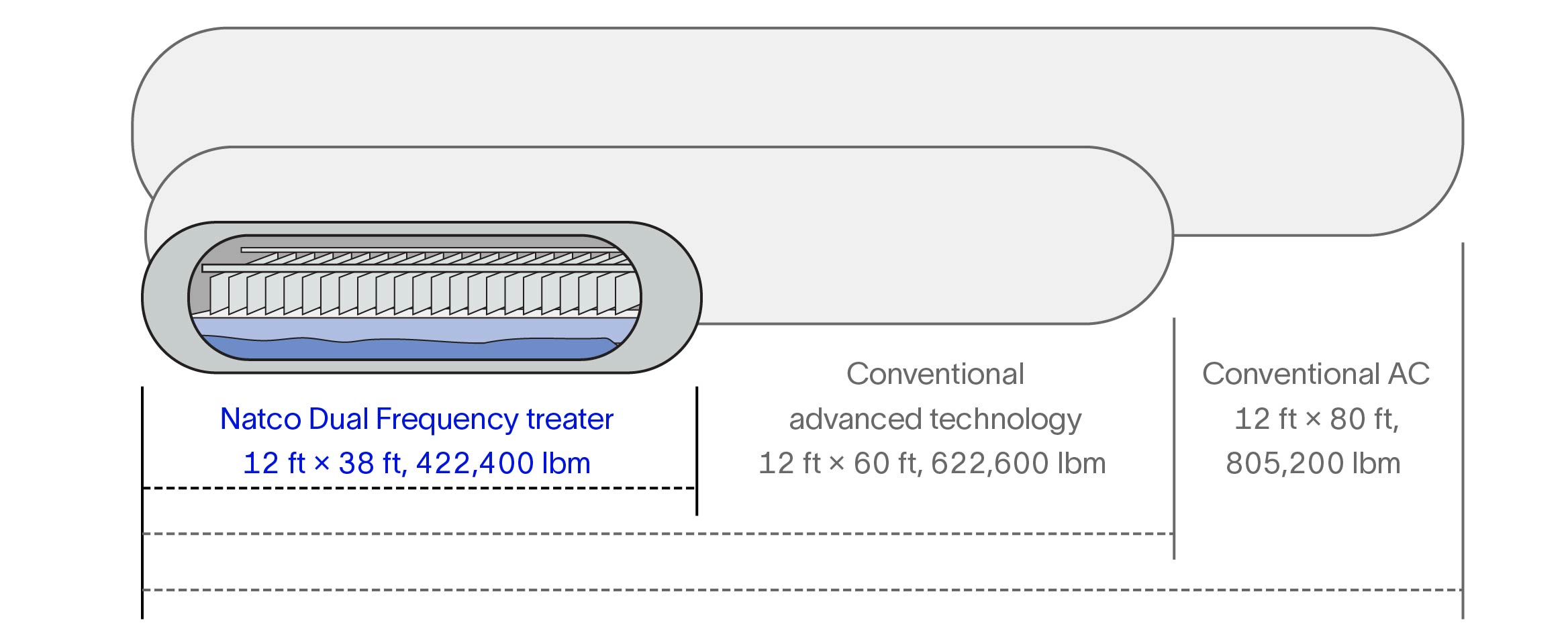

The vessel's superior hydraulic efficiency—enabled by our HiFlo spreader’s uniform distribution of vertical flow through the treater and electrodes—eliminates fluid bypass and zones of local recirculation, providing the highest level of dehydration. The high flux per square foot enables a smaller pressure vessel and therefore less embodied carbon, both for newly built and retrofitted dehydration and desalting process equipment.

Natco Dual Frequency treaters allow you to adjust and optimize the electrostatic processing parameters in real time. To break emulsions, the electrostatic treater transformer enables adjusting the shape and amplitude of voltage waveforms applied to the electrodes. Appropriate adjustments optimize coalescence of the water droplets, leading to effective emulsion resolution and low water content in oil without having to rely solely on heating and production chemicals—which are still important factors in oil dehydration and desalting. The ability to tune the electrostatic fields reduces heating requirements and therefore, energy consumption and emissions. Heat, production chemicals, mixing, and time eliminate barriers to dehydration, but the electrostatic fields provide the muscle to aid water droplet growth and gravitational separation.

† Compared with conventional AC and AC-DC electrostatic treater technology

Natco Dual Frequency electrostatic coalescers separate increasing volumes of produced water in a single stage and remove salt from produced crude more sustainably than AC electrostatic coalescers. They are especially useful as fields age and upstream gravity separators, often designed for smaller water treatment volumes, are unable to cope. As new reservoirs, reservoir compartments, or both are produced, fluid properties often differ from the separator's original design basis and the salt content of the water produced with crude oil often changes, making it challenging to meet commercial specifications for pounds of salt per thousand barrels of oil. Moreover, mixing crude oils with different compositions and solids content frequently generates challenging stable oil emulsions and increases crude oil conductivity. Both phenomena degrade the ability of water droplets to collide, grow, and gravitationally separate, increasing the need to add a demulsifier.

Natco Dual Frequency dehydrators and desalters provide the flexibility you need in your production processing designs to manage the uncertainty inherent in field development planning, especially for heavy crude oil—where electrostatic dehydration may be challenging because of smaller differences in oil and water densities—or when the produced water has very low salinity. They are also ideal for retrofitting existing facilities during planned turnarounds to reduce unit delivery costs when oil production is declining or when you need to add capacity but space and electricity supply are limited. In either case, you will greatly reduce your electric power requirements and consequently, your Scope 1 or 2 emissions.

The treater can be delivered as a heater treater, providing heating and dehydration in a single vessel and eliminating the need for an externally heated heat transfer fluid. It can also be supplied as a degassing treater, eliminating the need for a separate degasser.

Natco Dual Frequency electrostatic desalters desalt a wide range of crude oil slates more sustainably than AC technology. Based on years of scientific observation and evaluation at our Process Systems Technology Center and subsequent validation during refinery commissioning and operations, we've identified oils that have very high conductivity because of their inherent composition. Crude oil conductivity is also a function of temperature. Moreover, blending feedstocks from different sources and with different API gravities can increase conductivity.

High conductivity reduces the effectiveness of AC-generated electric fields in coalescing the small washwater droplets and desalting the crude oil charge entering the refinery process. This poor performance of legacy electrostatic technologies makes it challenging to meet downstream fluid specifications for pounds of salt per thousand barrels of oil—even in multistage AC desalting systems. Natco Dual Frequency electrostatic desalter is not particularly sensitive to oil conductivity because the applied voltage, base and modulation frequencies, and waveform parameters can be adjusted—a differentiated feature for dealing with highly stabilized emulsions that is unique in the market.

Natco Dual Frequency desalters provide the flexibility you need for initial refinery desalting process designs to manage the uncertainty inherent in crude oil supply. They are also ideal for retrofitting existing facilities during planned turnarounds to increase feedstock composition handling flexibility or when you need to add capacity but space and electricity supply are limited. In either case, you will greatly reduce your electric power requirements and consequently, your Scope 1 or 2 emissions.

The fourth-generation Natco Dual Frequency electrostatic treater's power unit includes several upgrades to enhance the process engineer's visibility and ability to tune the electrostatic dehydration and desalting process. Additionally, the plant electrical engineer's maintenance has been simplified compared with the previous-generation treater. All modifications are the result of feedback from operators and refiners using the third-generation technology.

Unlike legacy electrostatic treater transformers, which rely on inefficient, voltage-limiting reactors for overcurrent protection, our fourth-generation power units incorporate microcontrollers to proactively manage the current, protecting the unit while reducing energy usage and hence emissions.

The fourth-generation power unit can operate at higher ambient temperatures and with wider power variations. In addition,

The following SLB products are protected by patents in the U.S. and elsewhere. This website is provided to satisfy the virtual patent marking provisions of various jurisdictions including the virtual patent marking provisions of the America Invents Act and to provide notice under 35 U.S.C. §287. The following list of SLB products may not be all inclusive, and other SLB products not listed here may be protected by one or more patents.

Natco Dual Frequency: Protected by U.S. Patents US 7,758,738; US 10,913,013; US 8,900,460; US 9,115,316; US 9,422,484; US 10,112,850; US 10,745,301; US 10,590,017; US 11,794,131; US 11,801,457; US 12,095,376; US 11,398,781; US 12,128,330; US 12,121,830. Additional patents may be pending in the U.S. and elsewhere.

Within the Natco Dual Frequency treater, bulk water and larger water drops are coalesced and separated by gravity in the weaker AC field that exists between the grounded water phase and the electrodes. The stronger DC field between the electrodes causes rapid movement of the remaining small water droplets through electrophoretic attraction, causing them to collide, coalesce, grow, and separate by gravity. The modulated voltage waveform ensures coalescence without fragmenting (which would arrest water droplet growth), enabling droplets to descend to the bottom of the vessel via gravity. This electrostatic separation process has a higher flux per square foot, which reduces vessel size requirements, while the advanced power unit decreases electric power demand.

In desalter applications, washwater is injected through a proprietary injection quill upstream of the mixing valve in the inlet piping. Together with the electrophoretic movement of the water droplets, this provides a very high degree of mixing. Superior mixing and improved dehydration make the Natco Dual Frequency treater much more effective than conventional AC desalters of similar size.

Use of a high base frequency for the electrostatic field provides stronger electrostatic forces even in high-conductivity crudes and crude blends. Low-frequency amplitude modulation of the field improves conditions for water droplet coalescence, further enhancing dehydration and desalting efficiency.

We also retrofit existing AC treaters to improve their capacity.

Natco Dual Frequency electrostatic treater is part of our Transition Technologies™ portfolio. Learn about our collaborative approach and full field development solutions that drive high performance while reducing environmental impact throughout the life of your asset.

Read MoreThe content of this publication has not been approved by the United Nations and does not reflect the views of the United Nations or its officials or Member States.