Significantly improve footage and ROP in hard-to-drill formations.

StingBlade Bit Saves ENAP SIPEC 1.5 Days by Drilling Abrasive Formation Interval in One Run

Published: 08/02/2016

StingBlade Bit Saves ENAP SIPEC 1.5 Days by Drilling Abrasive Formation Interval in One Run

Published: 08/02/2016

Efficiently drill highly abrasive interbedded formation

A challenging interval of Ecuador's Paraíso Biguino Hauchito Intracampos (PBHI) block is the Tiyuyacu Formation, which consists of claystone, sandstone, and conglomerates of quartz, chert, and pebbles. Because of its composition, the Tiyuyacu Formation represents a high-impact, high-abrasiveness environment that can cause damage to conventional PDC bits. The control of drilling parameters—including surface rpm, surface WOB, and flow rate—is critical for reducing total rpm on the bit and impact on cutting structures.

ENAP SIPEC was constructing wells in the PBHI block that would drill through the Tiyuyacu Formation. The well plan included a dual-casing approach and reaching well TD in the 12 1/4-in section between 9,900-ft and 10,330-ft TVD with an S-type profile. In an offset well, the operator required two bits and BHAs to drill the Tiyuyacu Formation and four bits and BHAs to complete the 12 1/4-in section.

Pair StingBlade bit with powerful PDM for enhanced performance

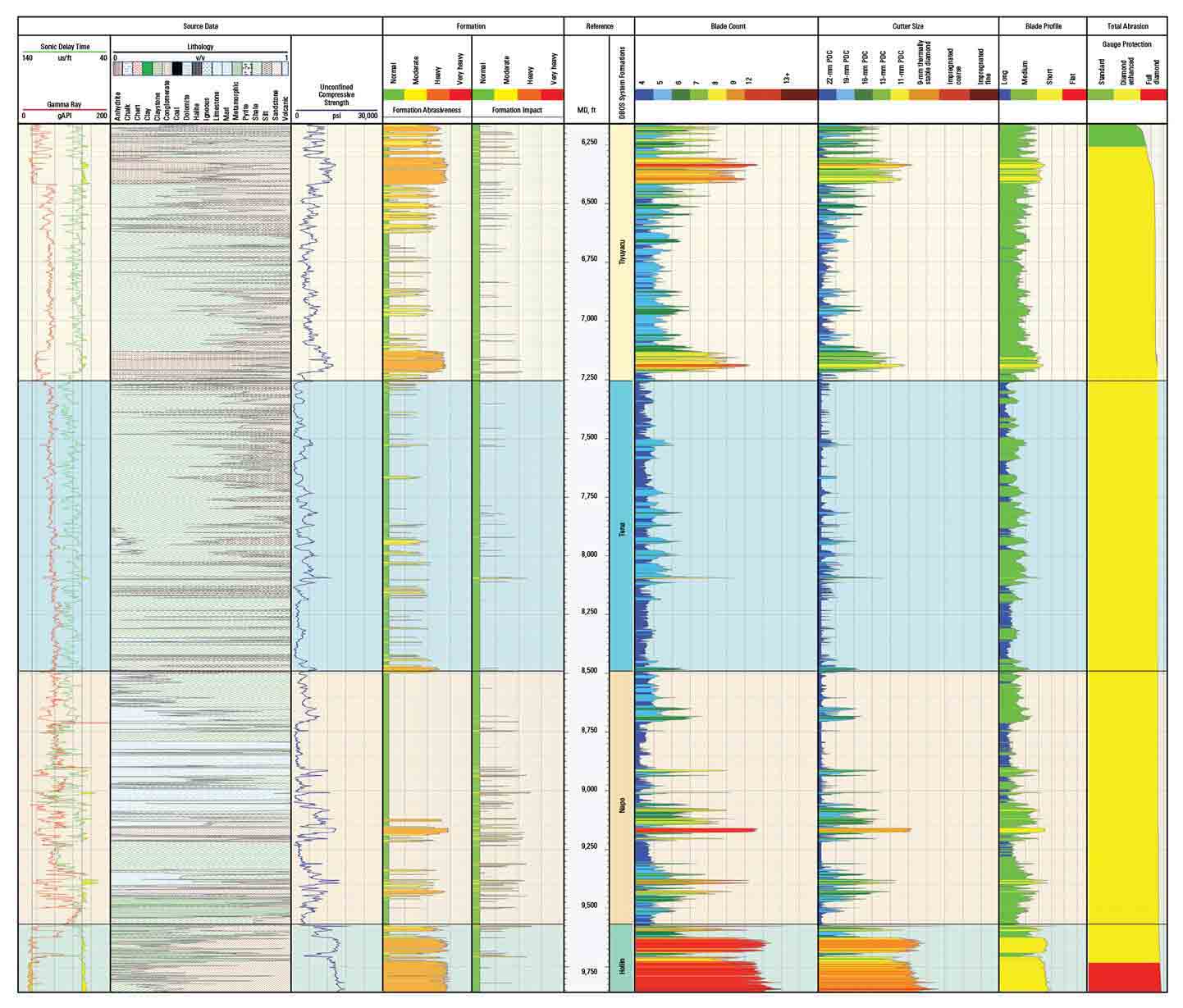

Schlumberger engineers used the DBOS drillbit optimization system to analyze the formation hardness and abrasiveness—information that was used to optimize the drillbit selection. After analyzing the formation and offset well data presented by Schlumberger, the ENAP SIPEC engineering team chose to run the 12 1/4-in StingBlade conical diamond element bit. The technology provides superior impact resistance by leveraging the durability of Stinger diamond conical elements, which are strategically positioned across the bit face.

Engineers also selected a powerful Schlumberger PDM to complement the StingBlade bit’s performance. Because the StingBlade bit features increased durability and ROP potential, the PDM was optimized for higher flow rates, output torque, and rpm. The technology and fit-for-purpose drilling parameters would enhance hole cleaning without compromising drilling power.

Save significant drilling time across multiple wells

The StingBlade bit and Schlumberger PDM not only drilled the Tiyuyacu Formation but the Tena and Napo Formations as well, extending the run by 1,332-ft MD. This single-run performance demonstrates a significant improvement over offset wells, which required two bits and BHAs to reach the same depth. The 12 1/4-in section was completed with two BHAs—compared with four in the offset well—saving ENAP SIPEC 1.5 days versus AFE.

The operator requested that the same drilling configuration be used on the 12 1/4-in section of its next two wells, where the integrated drilling solution delivered similar improvements to drilling efficiency.

![Graph - The StingBlade bit helped drill 2,369-ft [722-m] MD at an ROP of 57.8 ft/h [17.6 m/h], achieving TD faster compared with offsets. This performance spurred the operator to use the technology on two additional wells, where the technologies demonstrated equally significant drilling improvements.](/-/media/files/smith/case-study/stingblade-ecg-enap-sipec-cs-b.jpg)

Challenge: Drill 12 1/4-in well section through high-impact, highly abrasive conglomerates of the Tiyuyacu Formation, which historically requires multiple bits to complete.

Solution: Deploy StingBlade conical diamond element bit and optimized Schlumberger positive displacement motor (PDM) to withstand the formation and reach well TD.

Results:

- Exceeded customer expectations by drilling Tiyuyacu Formation as well as two additional formations, extending the run by 1,332-ft [406-m] MD.

- Completed the 12 1/4-in section with two bits and BHAs compared with four required in offset wells.

- Applied integrated drilling BHA on two additional wells and achieved similar improvements in drilling efficiency.