Decarbonize oil and gas production

Leverage technologies and solutions that reduce greenhouse gas emissions from every barrel produced

Challenge

Get closer to where—and when—counts most

Because production operations produce the largest proportion of greenhouse gas emissions (GHG) in the oil and gas value chain, they present the biggest decarbonization opportunity. Yet, we must consider decarbonization within the context of commercial reality and not in isolation. Maximizing ROI and minimizing emissions per barrel requires the right approach to tackling carbon emissions at their root cause.

Getting closer to the action

We'll help you find the right solutions for your assets and get close to emission sources across production operations. This can include leveraging our growing portfolio of Transition Technologies™ for opportunities to reduce energy consumption, increase efficiency, and minimize carbon emissions. Our solutions address some of the biggest challenges across multiple dimensions:

- Distance between the reservoir and the location where emissions occur

- Delay between the creation of unwanted byproducts and their treatment

- Gap between concepts and field-proven solutions

Explore our Transition Technologies portfolio

Increase lifting efficiency

Lifting fluids consumes a lot of energy. These technologies maximize energy efficiency and minimize emissions.

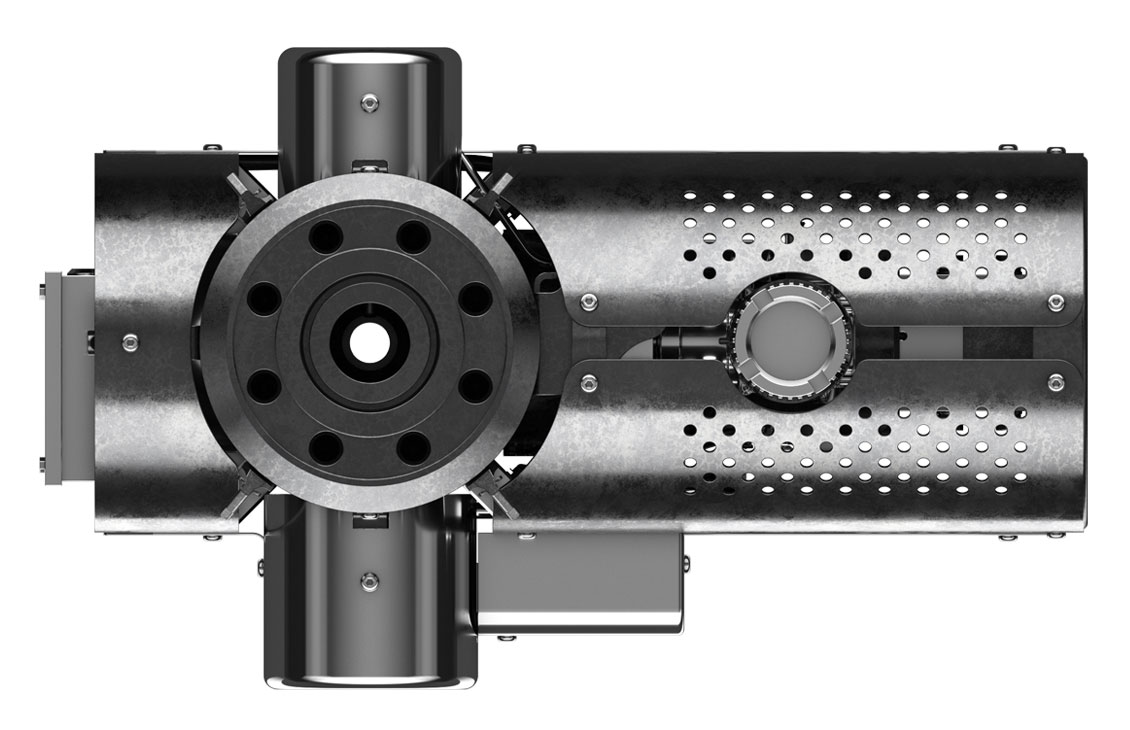

Subsea boosting (pumps)

Increase well flow and recoverable reserve with our subsea pumps

Increase well flow and recoverable reserve with our subsea pumps

Subsea compression

Provide flexible solutions with the highest flowrates and pressure ratio capabilities in the industry

Provide flexible solutions with the highest flowrates and pressure ratio capabilities in the industry

ESP Permanent Magnet Motors

Reduced energy costs and improved ESP performance

ESP Permanent magnet motors have power efficiency, power factor, and power density and help lower electricity consumption.

Reda Maximus Eon

Extended-life, install-ready ESP motor

Maximus Eon motor delivers greater electrical power efficiency, supporting your emissions reduction goals.

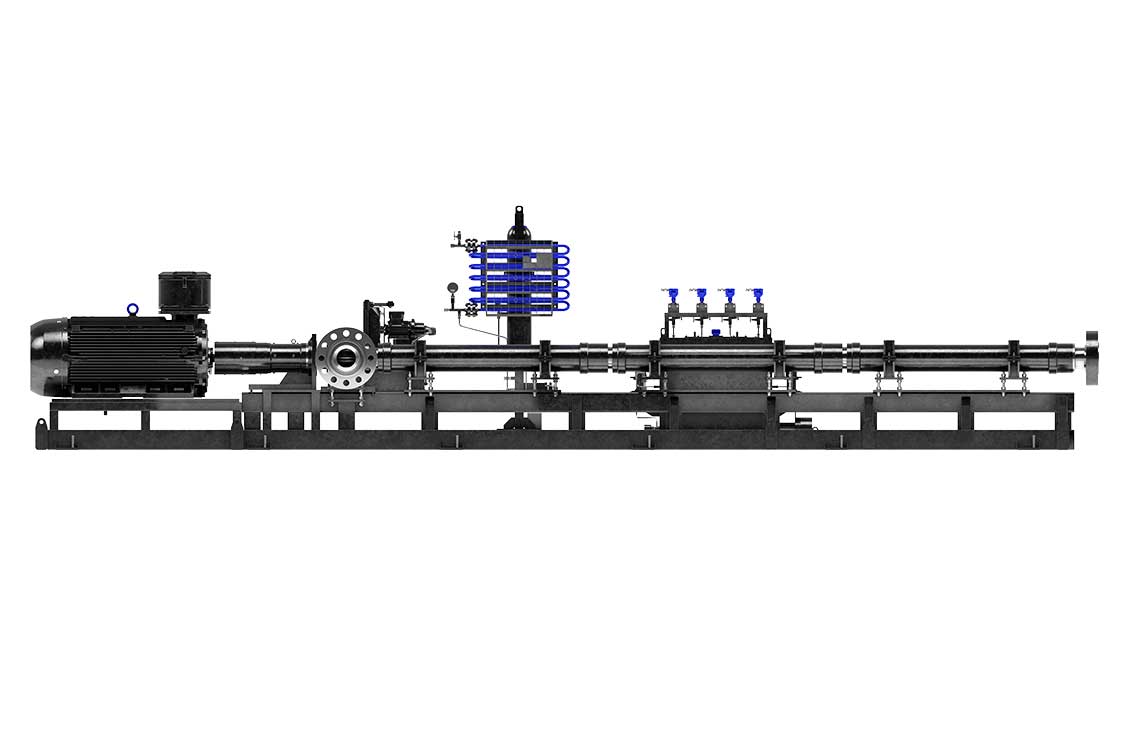

Reda Multiphase HPS

Horizontal multistage surface pump

Handles up to 90% gas volume fraction; used for zero-flaring well tests, well cleanup, and production boosting.

Create low-footprint infrastructure and minimize emissions per barrel

Production infrastructure represents a large investment. These technologies minimize its size while ensuring the flexibility for minimizing carbon per barrel throughout your asset's production life.

Rapid multilateral junction systems

Extend reach. Maximize contact. Simplify control.

Enhance reservoir contact and simplify multilateral well construction with SLB’s Rapid Multilateral Systems. Configurable from TAML 2 to 5, Rapid technologies deliver fullbore access, intelligent completion integration, and selective intervention capability.

Manara

First-generation electric interval control valves

Optimize recovery and reservoir management by monitoring and controlling flow from multiple zones in real time.

Electric surface actuator

Electrification, digitalization, and predictive condition-based maintenance of surface valves

Reduce opex, capex, and environmental impact.

Vx Spectra

Surface multiphase flowmeter

Accurately measure the full spectrum of multiphase flow rates while monitoring production in real time.

Drive process efficiency

Fluid processing and separation requires a lot of heat and mechanical energy for rotating machinery such as pumps and compressors. Our proven solutions cut emissions for each treated barrel.

Cynara

H2S and CO2 separation membranes

Separate acid gases from produced natural gas without chemicals.

Natco Dual Frequency

Electrostatic treaters, coalescers, and desalters

Use both AC and DC power to significantly improve processing vs. conventional AC electrostatic technologies.

THIOPAQ O&G

Oil and gas biodesulfurization system

Convert H2S in gas streams to solid sulfur ready for agriculture or disposal.

SELECT S

Hydrogen sulfide removal adsorbent

Mixed-metal-oxides-based adsorbents to remove harmful H2S from liquid and dry and water-saturated gas streams.

Mechanical Vapor Recompression for PureMEG System

Capture waste heat for monoethylene glycol (MEG) reclamation and regeneration

Reduce utility demand, opex, and greenhouse gas (GHG) emissions.

Learn how we get closer to the action

SLB Footprint Reduction

The technologies featured on this page are part of our Transition Technologies™ portfolio. Explore how these differentiated products and services support oil and gas decarbonization across the E&P value chain.

Learn more