Connected Wellhead System

Harness real-time data for optimal performance and unwavering reliability

Digitalization provides control and data to reduce cost, minimize HSE risk, and maximize reliability.

Aligns with United Nations Sustainable Development Goals 12 and 13

Avoids up to 1.8 metric tons of C02e per actuator per year

Saves 2.2 MW.h per actuator per year

Enables smaller footprint and highly reliable normally unattended facilities (NUF) with electric actuators and control systems that reduce maintenance needs

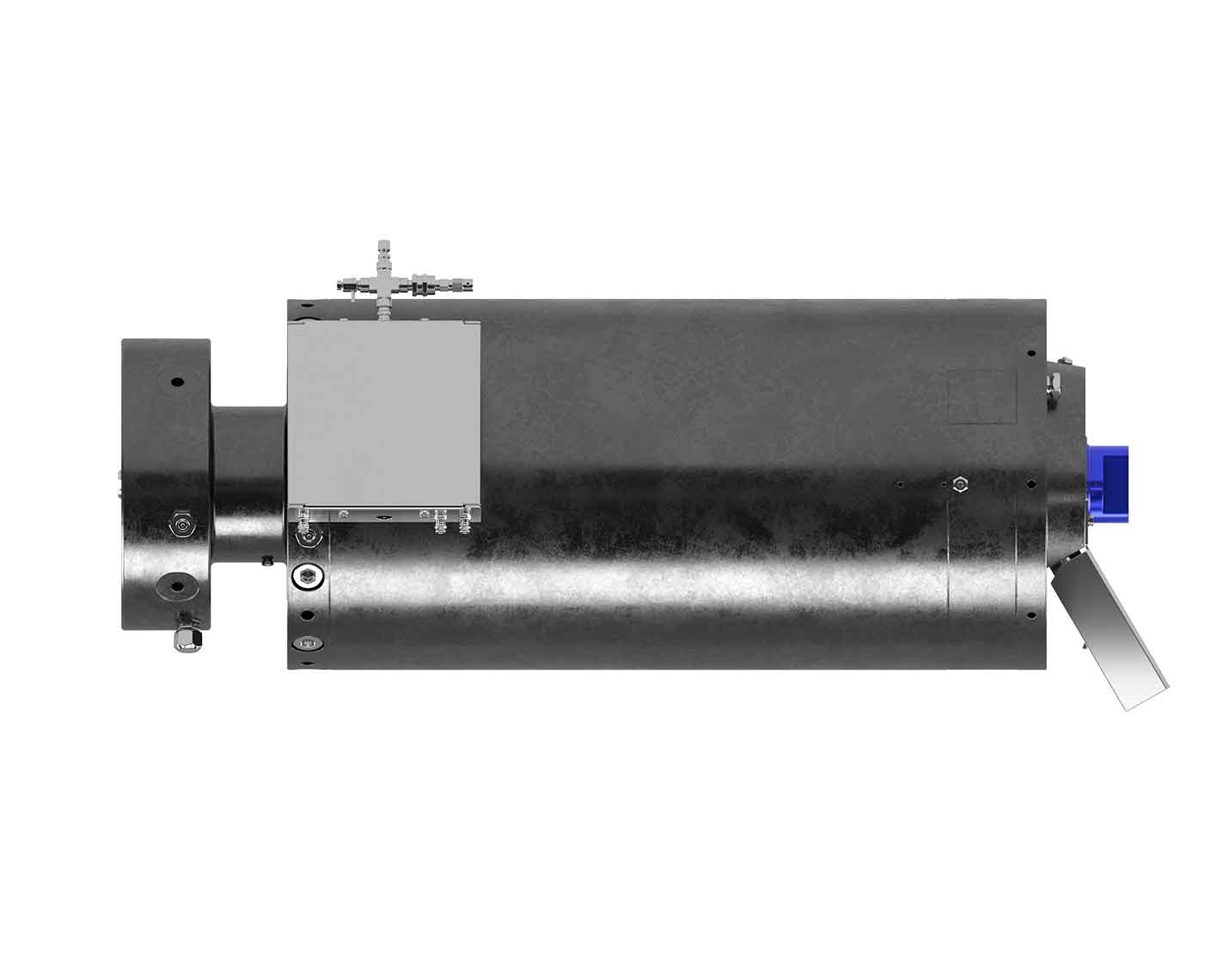

Our electric surface actuator is designed for offshore platforms—especially ones with no permanent crews—and remote or difficult-to-access onshore oil fields. It is suitable for retrofitting most standard wellheads and trees and supports a fully electric system and future automation. The electric surface actuator has a proven 30-year life and 5 years of maintenance-free performance.

The electric surface actuator lowers your opex by up to 30% via reliable, long-term remote control of surface valves as well as condition-based monitoring and money-saving predictive maintenance. By eliminating unnecessary site visits and personnel on location, these actuators enable you to rethink platform design, potentially removing costly structures such as helidecks, living quarters, and control rooms. Reducing maintenance visits also decreases CO2 emissions. Asset field crews can run leaner because technicians are better informed about the maintenance required.

Hydraulic actuators require periodic control fluid replacement and disposal and are sensitive to control fluid contamination. They must be monitored for leaking control lines and the overall control system consumes more energy. The increased energy consumption along with high interval maintenance requirements create higher CO2 emissions.

Pressure rating: up to 10,000 psi

Available for gate valve sizes from

2 1/16 in to 6 3/8 in

Input voltage requirements: 3-phase 480 VAC. See datasheet details.

The electric surface actuator comes with integrated sensors which track actuator position, monitor housing pressure, and measure current for main actuator components. Valve sensing can also be included to identify gate and stem leaks. These features can be integrated into a smart actuator control system.

Actuator designs are fail-close, using a clutch to disengage the valve from the electrical system and enable a mechanical spring to rapidly close the valve.

The sensors interface with your SCADA systems or distributed control systems (DCS) using industry-standard communication protocols.

To complement the electric surface actuator, SLB has designed a smart control system equipped with programmable logic control (PLC), servo drive, and handheld wireless tablet with HMI. This intelligent control system manages the electric actuator valve open-close operations and provides condition monitoring of various components of the electrical actuator, valve, and tree. The control system software is configured with partial stroke test capability for the fail-safe actuators and facilitates remote well testing.

The control system can be integrated into any wellhead control panel configuration where it can be operated via a platform safety system using various industry standard communication protocols, such as MODBUS®, OPC UA™, or PROFINET™. While specific open and close routines are handled by the local software within the CPU, sequencing, and decisions of valve operations on the tree are controlled by the platform safety system.

All fail-safe main actuator drive electronics are located away from the valve and tree for ease of installation, maintenance, and troubleshooting. For these safety functions, this separation ensures that sensitive electronics are kept out of the red zone and away from what can be a relative harsh environment.

Modbus is a registered trademark of Schneider Electric. OPC UA is a mark of OPC Foundation. PROFINET is a mark of PROFIBUS & PROFINET International.

The content of this publication has not been approved by the United Nations and does not reflect the views of the United Nations or its officials or Member States.