FLS-S

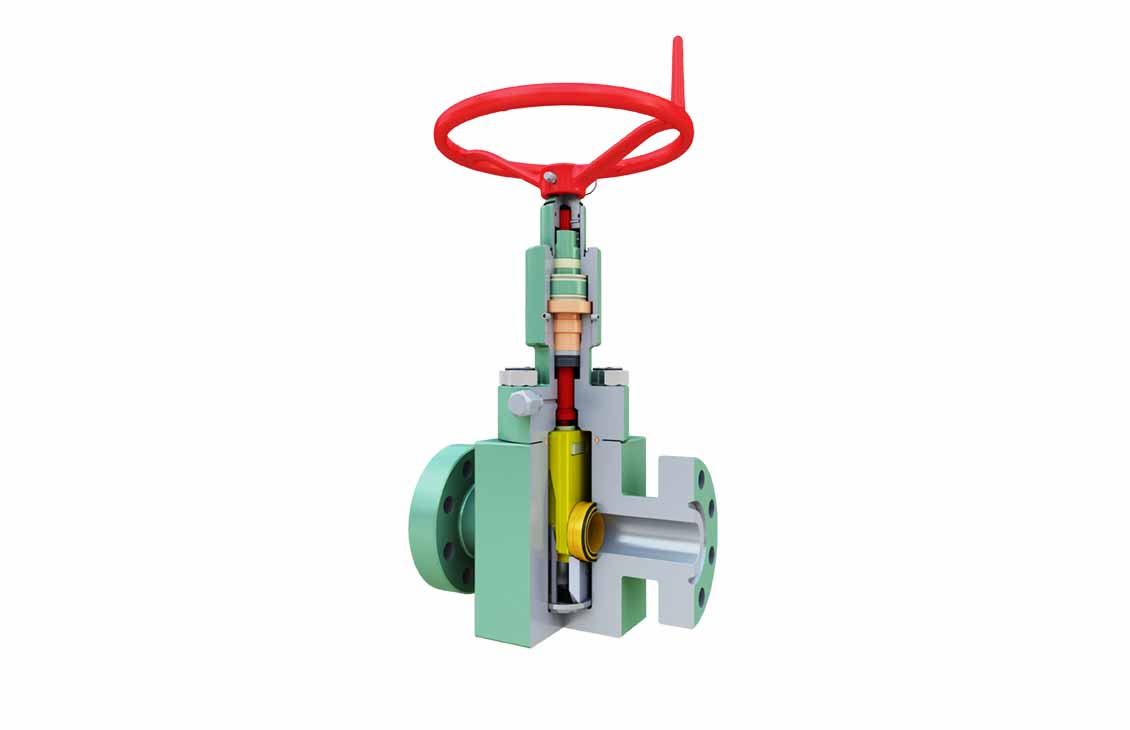

API 6A split slab-style gate valve

The Cameron FLS-S gate valve features forged construction, metal-to-metal sealing, and a split gate design that enables performing a single dual-seat seal test. Depending on valve actuation methods (either manual or power actuated), the two gates are energized mechanically by applying torque or spring forces to create the initial sealing.

When performing the seal test, the two gates first are energized mechanically to create the initial sealing. Test pressure then is applied and relieved through the bonnet grease fitting located behind the stem backseat. The valve is not intended to be stroked when performing a dual-seal test at full working pressure. A true shear pin is located in the valve handwheel adapter to protect over-torque and ease pin replacement.

This split gate design is available for all FLS and FLS-R valve pressure ratings and bore sizes.

Advantages

- Bidirectional design that provides flow direction versatility and increased service life

- Positive metal-to-metal sealing at the gate-to-seat and seat-to-body seals

- Simple, reliable gate and seat design that promotes ease of field service and minimal spare parts inventory

- Split gate design that allows for single seat test for both flow directions

- Two spring-loaded, pressure energized, nonelastomeric lip seals between each seat and body that assist in low-pressure sealing and protect against intrusion of particle contaminants into the body cavity and seal areas

- Stem seal design that covers the full range of pressures, temperatures, and fluids encountered in wellhead and manifold service

- Metal-to-metal bonnet seal

- Stem that can be backseated to allow stem seal replacement with the valve under pressure

- Grease injection fitting located downstream of stem backseat for safety

- Fitting located in bonnet for elimination of body penetration

- Bearing cap grease fitting that allows positive bearing lubrication

- Easy closing and sealing without excessive torque

- True shear pin protection from torque