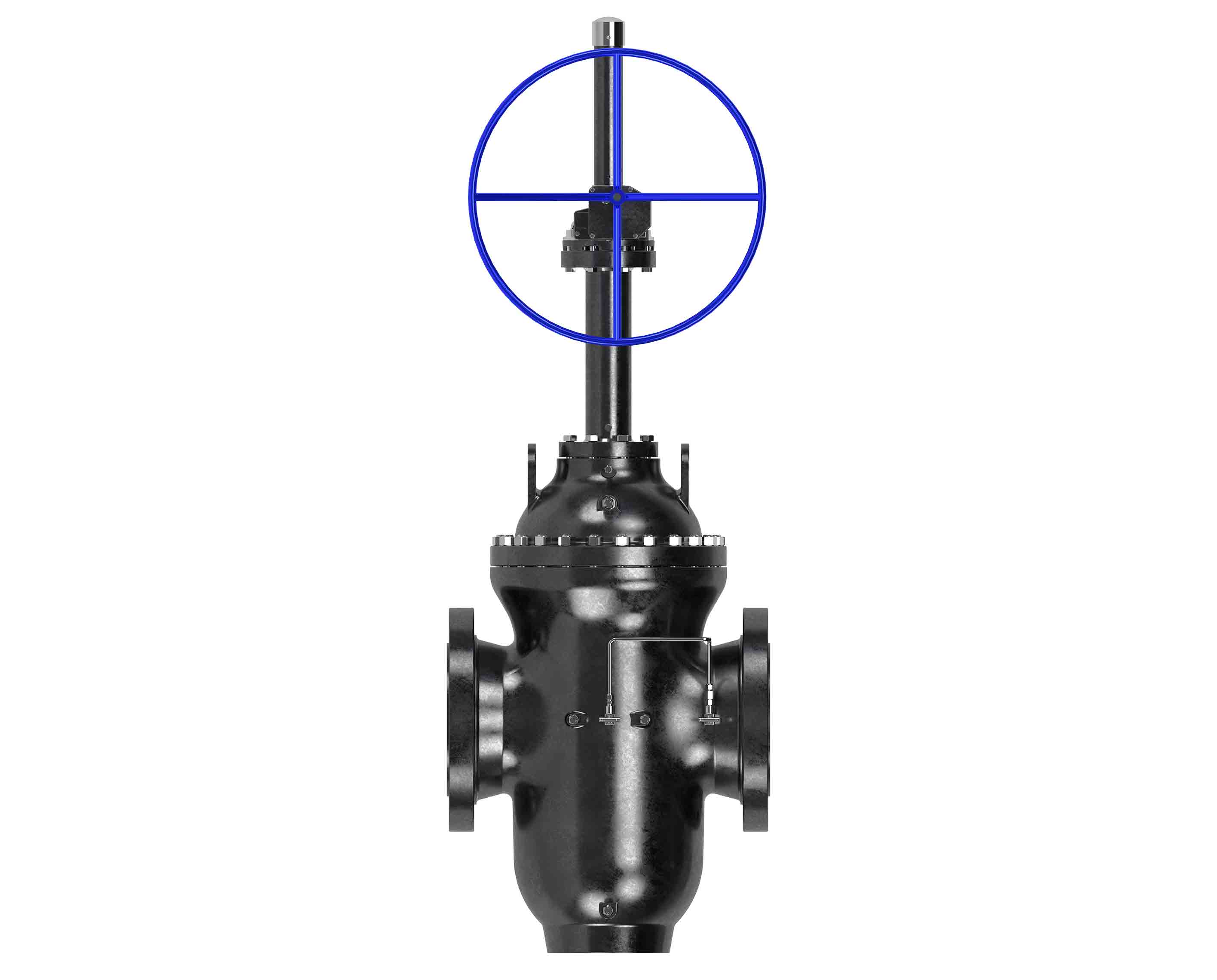

WKM Saf-T-Seal

Slab gate valve

Simple yet rugged and reliable through-conduit valve.

Double expanding gate valve

A 60-year record of worldwide service in oil, gas, chemicals, water, slurry, and multiproduct applications has established the WKM™ Pow-R-Seal™ double expanding gate valve as one of the most trusted gate valves, especially where safety and seal reliability are critical.

The positive mechanical seating force of the lock-in-place seals holds with zero leakage through vibration and pressure and temperature changes. The rigid, cast steel body resists pipeline bending moments.

PTFE seals on both faces of the valve provide drop-tight sealing even at low differential pressure, while metal-to-metal contact between the seats and gate mechanism ensures fire-safe shutoff. Optional all-metal seals are also available for service up to 1,000 degF [538 degC], where leakage rates comply with API Spec 6D.

Our Pow-R-Seal gate valve is the choice of pipeline operators transporting liquids because it tolerates the wax, paraffin, abrasives, and multiproduct flow that cause problems with other valve designs.

The wide range of applications includes

The Pow-R-Seal gate valve provides the following advantages:

The Pow-R-Seal gate valve uses an expanding gate design consisting of a two-piece gate and segment assembly. In the fully closed position, the segment has engaged with an end stop and the gate is wedged downward, expanding the segment and gate so that they form a tight mechanical closure against the upstream and downstream seats.

During travel toward opening, the gate slides across the wedge angle of the segment, collapsing the assembly so that it travels freely between the seal faces. Our lever-lock gate centralizer holds the mechanism in the neutral position until seal expansion is required.

When the bore in the segment is aligned with the conduit bore, an end stop prevents further travel and the gate slides across the wedge angle, expanding the gate and segment and isolating the flow from the body. The preferred flow direction ensures easier operation.