Facility Planner on Delfi

Oil & gas facility scoping, cost estimating, and project planning

Collaboratively analyze and simulate multiple facility concepts.

Electrostatic treaters, coalescers, and desalters

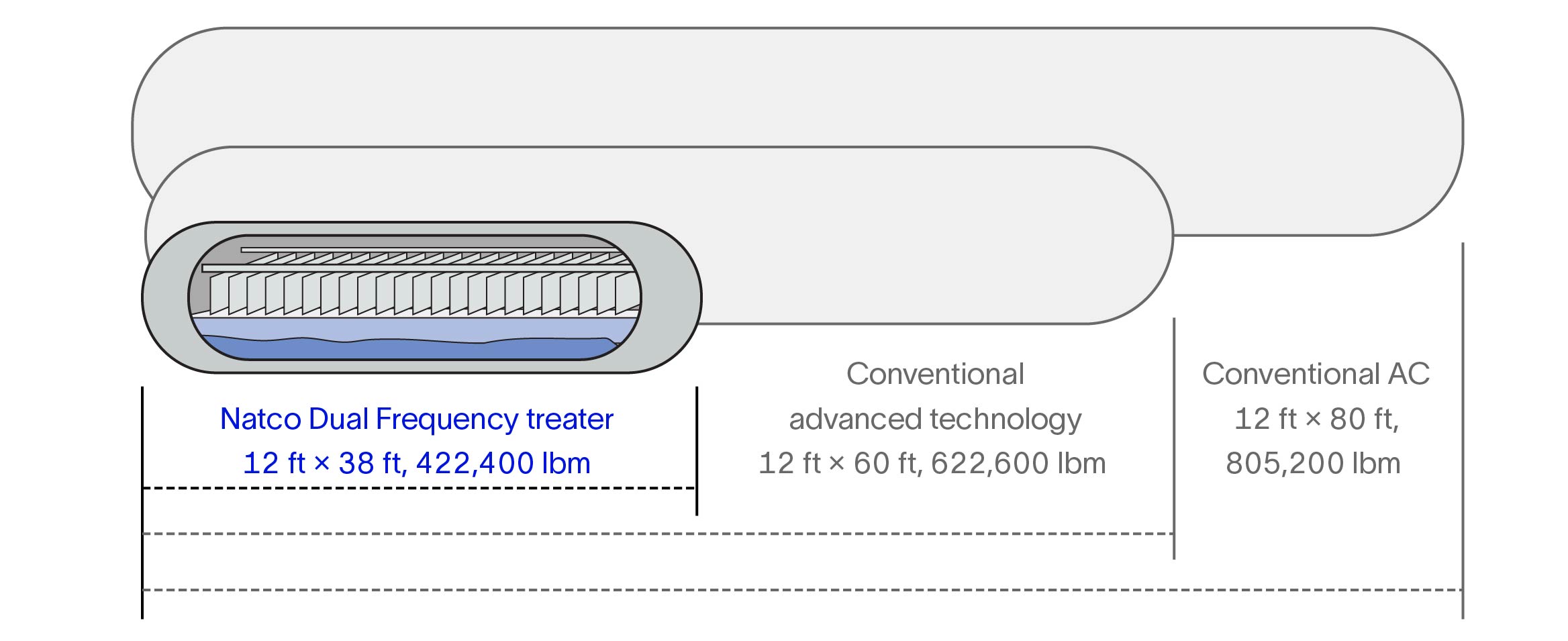

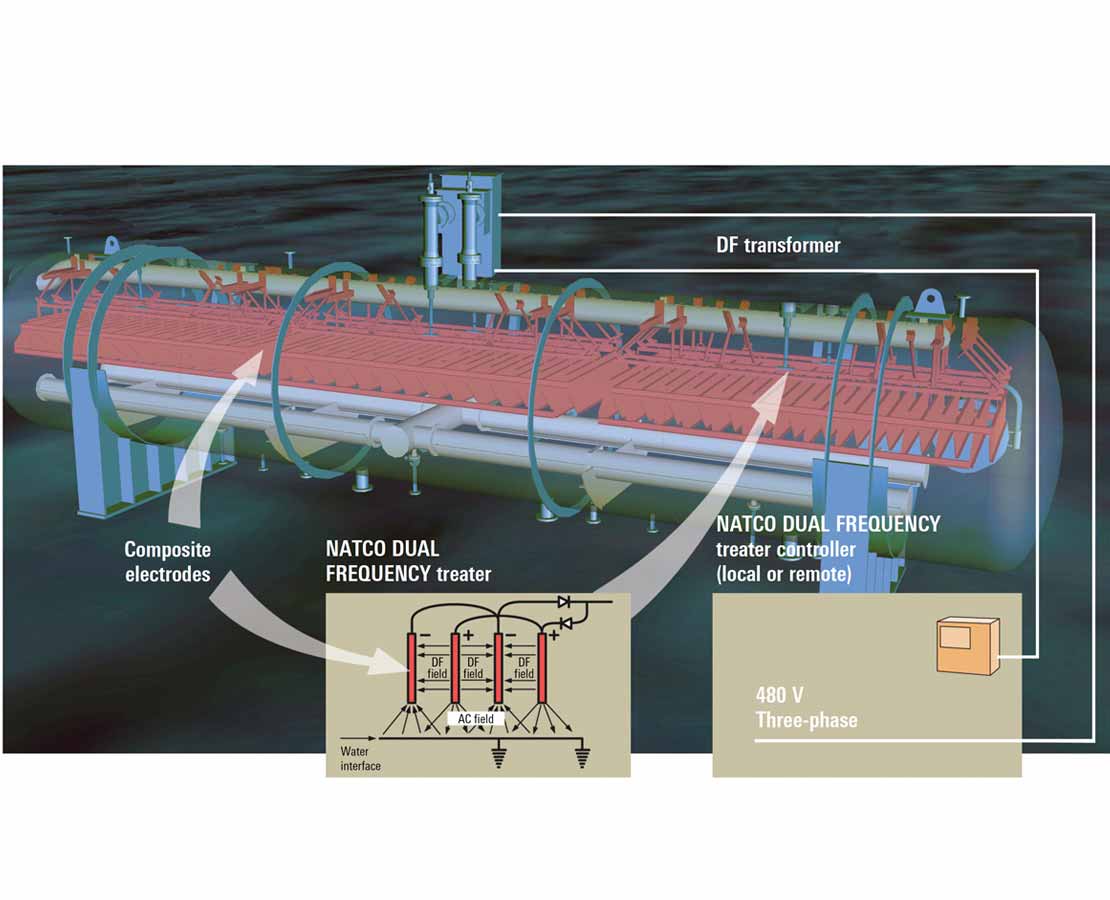

Cost-effective fourth-generation Natco Dual Frequency™ electrostatic treaters have lower annual power requirements than dehydration technologies that use AC-generated electric fields alone or conventional AC-DC technologies. The customizable bimodal AC-DC electrostatic field uses fewer watts per unit volume as it causes small water droplets dispersed within the wet crude to collide, grow, and separate by gravity. Lower electricity consumption leads to a reduction in emissions. In addition, this advanced AC-DC power unit—sometimes called an electrostatic treater transformer—decreases total connected power load and consequently, the heavy-duty high-voltage electrical infrastructure for power generation, power delivery on site, or both.

The vessel's superior hydraulic efficiency—enabled by our HiFlo spreader’s uniform distribution of vertical flow through the treater and electrodes—eliminates fluid bypass and zones of local recirculation, providing the highest level of dehydration. The high flux per square foot enables a smaller pressure vessel and therefore less embodied carbon, both for newly built and retrofitted dehydration and desalting process equipment.

Natco Dual Frequency treaters allow you to adjust and optimize the electrostatic processing parameters in real time. To break emulsions, the electrostatic treater transformer enables adjusting the shape and amplitude of voltage waveforms applied to the electrodes. Appropriate adjustments optimize coalescence of the water droplets, leading to effective emulsion resolution and low water content in oil without having to rely solely on heating and production chemicals—which are still important factors in oil dehydration and desalting. The ability to tune the electrostatic fields reduces heating requirements and therefore, energy consumption and emissions. Heat, production chemicals, mixing, and time eliminate barriers to dehydration, but the electrostatic fields provide the muscle to aid water droplet growth and gravitational separation.

† Compared with conventional AC and AC-DC electrostatic treater technology

The fourth-generation Natco Dual Frequency electrostatic treater's power unit includes several upgrades to enhance the process engineer's visibility and ability to tune the electrostatic dehydration and desalting process. Additionally, the plant electrical engineer's maintenance has been simplified compared with the previous-generation treater. All modifications are the result of feedback from operators and refiners using the third-generation technology.

Unlike legacy electrostatic treater transformers, which rely on inefficient, voltage-limiting reactors for overcurrent protection, our fourth-generation power units incorporate microcontrollers to proactively manage the current, protecting the unit while reducing energy usage and hence emissions.

The fourth-generation power unit can operate at higher ambient temperatures and with wider power variations. In addition,

Within the Natco Dual Frequency treater, bulk water and larger water drops are coalesced and separated by gravity in the weaker AC field that exists between the grounded water phase and the electrodes. The stronger DC field between the electrodes causes rapid movement of the remaining small water droplets through electrophoretic attraction, causing them to collide, coalesce, grow, and separate by gravity. The modulated voltage waveform ensures coalescence without fragmenting (which would arrest water droplet growth), enabling droplets to descend to the bottom of the vessel via gravity. This electrostatic separation process has a higher flux per square foot, which reduces vessel size requirements, while the advanced power unit decreases electric power demand.

In desalter applications, washwater is injected through a proprietary injection quill upstream of the mixing valve in the inlet piping. Together with the electrophoretic movement of the water droplets, this provides a very high degree of mixing. Superior mixing and improved dehydration make the Natco Dual Frequency treater much more effective than conventional AC desalters of similar size.

Use of a high base frequency for the electrostatic field provides stronger electrostatic forces even in high-conductivity crudes and crude blends. Low-frequency amplitude modulation of the field improves conditions for water droplet coalescence, further enhancing dehydration and desalting efficiency.

We also retrofit existing AC treaters to improve their capacity.

Natco Dual Frequency electrostatic treater is part of our Transition Technologies™ portfolio. Learn about our collaborative approach and full field development solutions that drive high performance while reducing environmental impact throughout the life of your asset.

Read More