Sucker rods and couplings

Improve lifetime performance with maximum quality manufacturing

Choose high-quality and highly corrosion-resistant coated rods and couplings from Schlumberger.

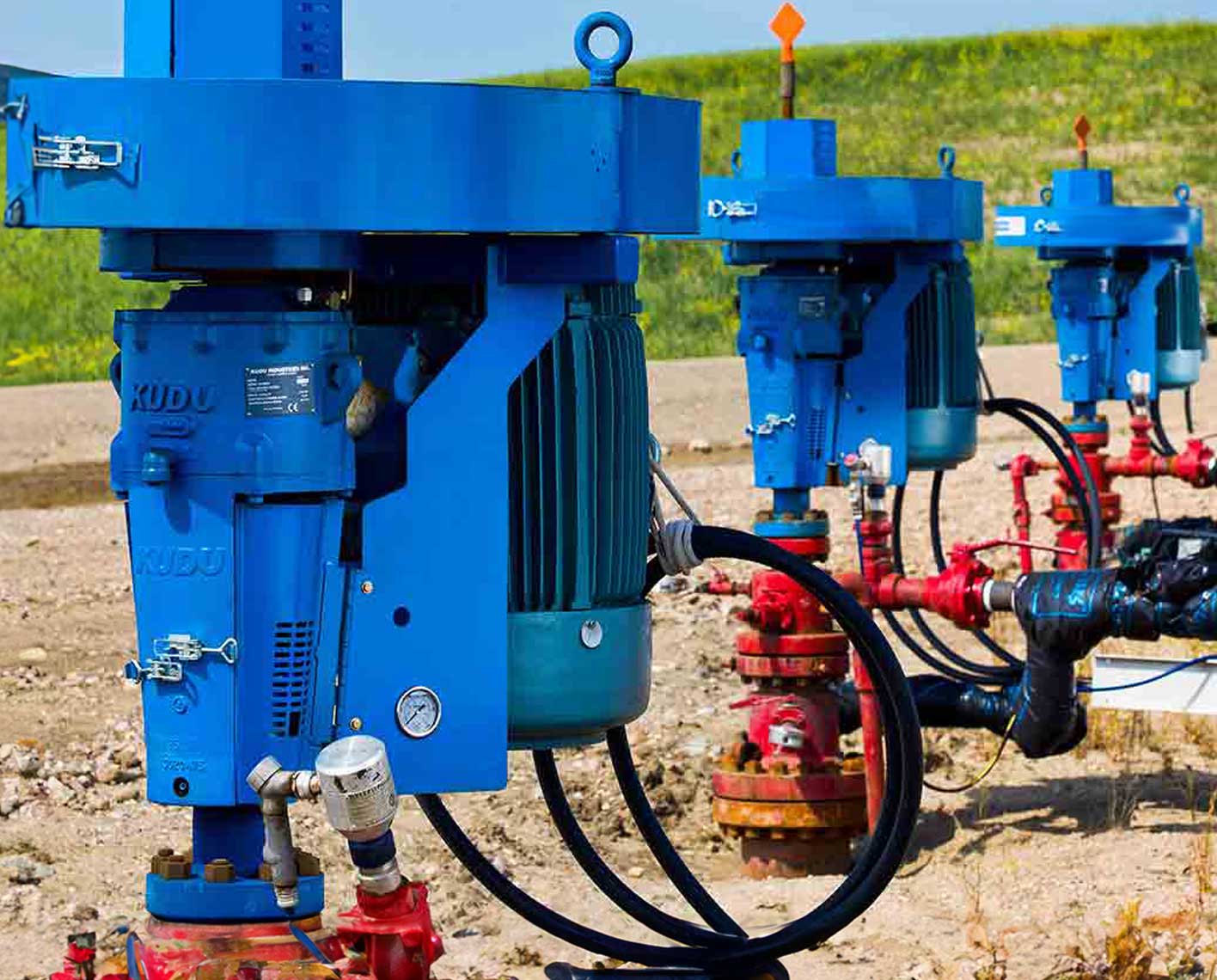

Downhole permanent magnet motor with progressive cavity pump eliminates sucker rodstring and friction challenges

Read case studyThe KUDU ESPCP PMM delivers constant and high torque across the full PCP speed range of 50 to 500 rpm. This flexibility enables accommodating a wide range of production rates without replacing the pump, which simplifies artificial lift planning and reduces capex and opex. No downhole gearbox or speed reducer is required.

A synchronous machine incorporating rare earth magnets in its rotor design, the PMM provides additional benefits, such as improved energy efficiency because of low power loss in the rotor and enhanced dynamic performance with a variable frequency drive (VFD) specifically designed for PMMs.

The system uses downhole telemetry to prevent pumpoff conditions, monitor equipment performance, and optimize well production in real time. A multisensor downhole gauge package measures intake pressure and temperature, well fluid and motor winding temperatures, vibration, and pump discharge pressure.

Downhole signals are interpreted by a data acquisition system on the surface and then sent to the VFD for monitoring, control, and recording.

Compatibility with ESP telemetry systems and completion technology—including the ESP cable— facilitates replacing an ESP with a KUDU ESPCP PMM and improves cost-effectiveness.