Dissolvable frac plugs

Reduce plug-and-perf duration and associated scope 1 and 2 emissions from postfracturing cleanout operations

Energy consumption reduction

Reduce diesel consumption by more than 5,700 L per 50-stage well by eliminating coiled tubing milling

Emissions reduction

Reduce CO2e emissions by 31,000 kg by using 100 dissolvable plugs instead of 100 composite plugs

Track record

Reduce diesel usage and resulting emissions from coiled tubing operations during plug-and-perf completions

Conventional frac plugs require milling out before production can start. These milling runs are performed as part of well cleanout operations, typically with a coiled tubing (CT) unit. Daily diesel consumption for a CT milling operation ranges from 4,000 L to 6,000 L. The fuel is required for pumps, injector heads, water treatment, cranes, and other ancillary support. Each liter of diesel adds 2.712 kg of CO2e emissions to the atmosphere.

Our ReacXion fully dissolvable frac plugs, on the other hand, easily dissolve in the presence of common wellbore fluids after hydraulic fracturing is complete, considerably simplifying cleanout operations and reducing time to production. The time savings results in reduced diesel consumption and hence, lower CO2e emissions. Dissolution performance is tuned with the optimal material for freshwater or brine.

Immediate production

Fullbore production

Longer laterals

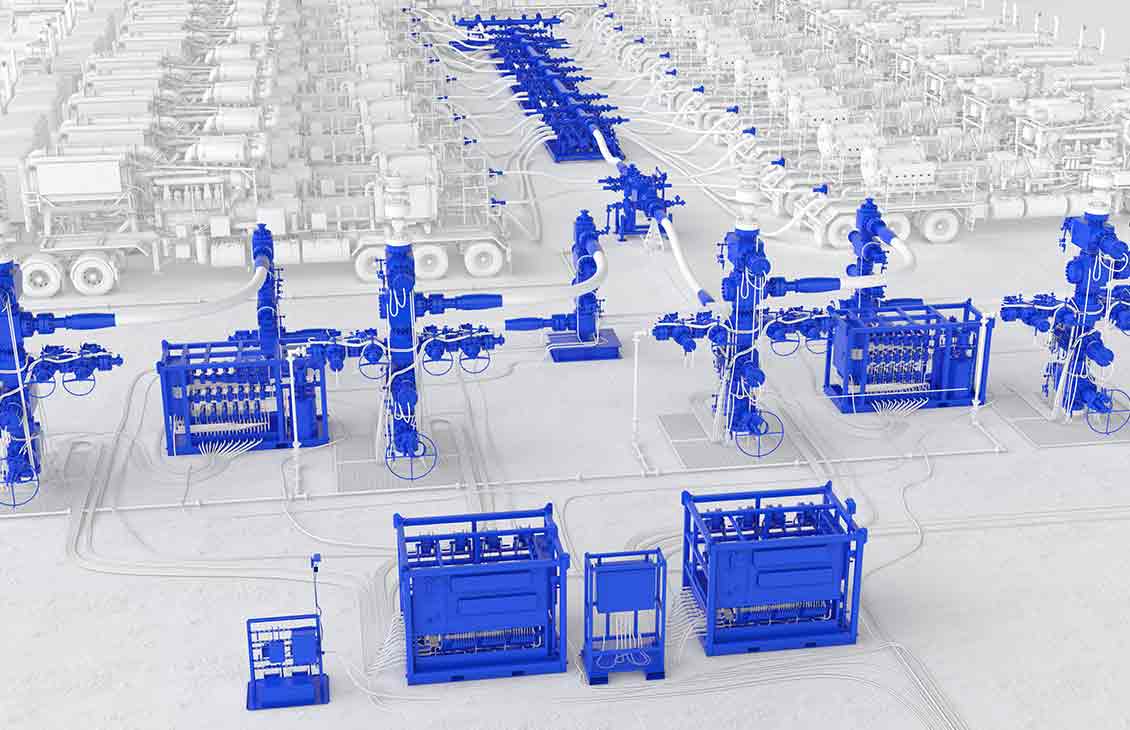

Is the Unity system what you need to improve your operational efficiency?

Learn more about how our Unity™ integrated frac plug and perf gun system can help you accelerate rig-up, reduce risk, and improve reliability.

Tell me more