Tech Paper Industry First Subsea Reentry Multilateral Wells

Technological breakthrough boosts recovery while minimizing costs, time to market, and environmental impact.

Increase production by expanding reservoir exposure

Benefits of multilateral technology can be enormous. Field development plans define well counts required to drain the reservoir―often with significant technical constraints and uncertainty. Multilateral well completions maximize reservoir contact per well, reducing the number of wells required. Having fewer wells simplifies surface and subsea infrastructure designs and reduces field development costs.

As fields mature, reservoir certainty increases, and near-field exploration offers additional opportunities to target accretive reserves; however, the production infrastructure is often slot limited. Meanwhile, if regulators or economics encourage operators to P&A dead or underperforming wells, they become an enticing target for sidetracking—even if they are not optimally positioned to reach the new reserves without complicated trajectories.

With retrofit multilaterals using RapidX TAML 5 high-strength, hydraulic sealed multilateral junction or RapidXtreme TAML 3, 4, or 5 large-bore multilateral junction, operators can select optimally positioned candidate wells to intersect accretive resource targets, with lateral initiation from intermediate or production casing―greatly reducing infill drilling and completion complexity and maintaining the production from the existing main bore.

Without adding additional infrastructure, RapidX junctions deliver access to up to 8,000,000 bbl of oil from subsea reservoirs with minimal CO2 emissions impact.

READ CASE STUDYMultilateral well construction and completions reduce generated and embodied carbon during field development. Drilling rigs that are used to drill the boreholes represent sources of generated carbon of varying intensity based on their power source and consumption. Steel casing and cement that are used to construct wells represent sources of embodied carbon of varying intensity based on their source of origination.

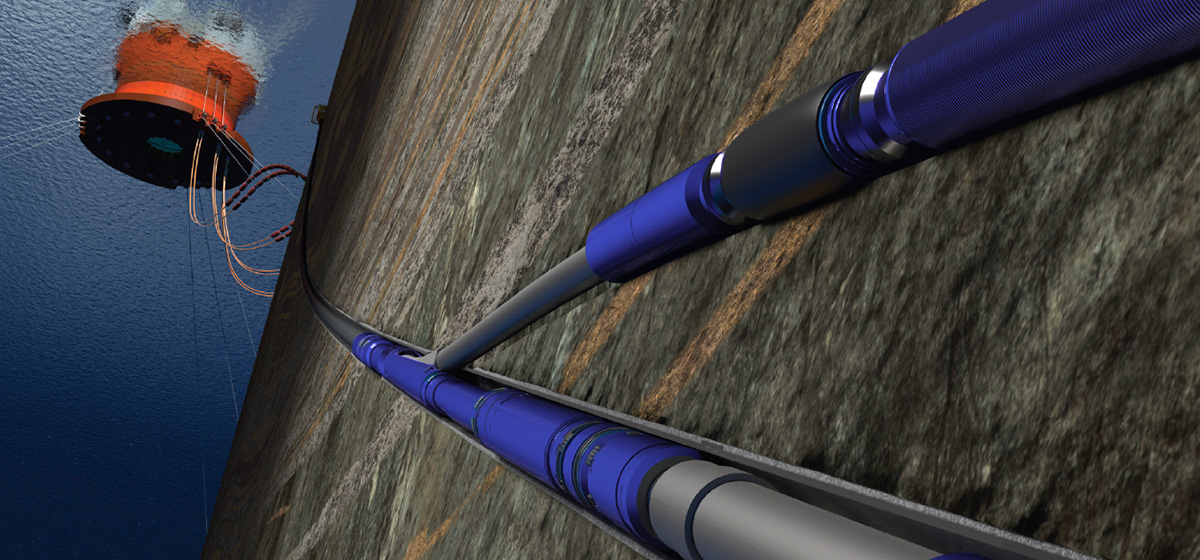

By targeting accretive reserves with a multilateral junction versus drilling a new well or sidetracking a poorly placed well, operators avoid carbon-generating activities by eliminating rig time―in some cases, 10 days or more. Operators reduce embodied carbon sources by eliminating procurement and installation of multiple steel casing strings and cement to surface; instead, they initiate the multilateral junction casing exit deep in the producing well. Operators further reduce embodied and generated carbon sources in the subsea environment by eliminating procurement and installation of additional subsea production system components, including subsea umbilicals, risers, and flow lines (SURF) that require specialized subsea construction vessels.

The carbon savings equates to 5 to 55 million miles [8 to 89 million km] driven by an average passenger vehicle, as determined using a US EPA greenhouse gas equivalencies calculator.

RapidX and RapidXtreme multilateral junctions are part of our Transition Technologies portfolio, offering collaborative full-field development solutions to sustainably drive high performance for decreased carbon impact. They maximize the value of existing infrastructure and reduce total well count, simultaneously minimizing emissions and maximizing business benefit.

Learn moreRapid multilateral systems enable you to consistently and repeatedly add laterals to increase reserves while minimizing investment.

Laterals can be planned as part of a greenfield development strategy from the outset to reduce total well count or to overcome the challenges of developing a complex field with horizontal extended-reach multilateral wells. They can also be added later during reentry as retrofit multilaterals to maintain production from the original well while targeting a nearby reservoir resource or to target and produce from accretive reserves while reducing surface or subsea infrastructure cost, lead time, and complexity.

Whether you're developing a reservoir on land or offshore, SLB has the technology you need to optimize your field development costs. Onshore, for example, surface constraints for conventional or unconventional fields can be eliminated. Offshore, on fixed or floating platforms with dry trees, slot limitations and near-platform collision avoidance challenges are reduced or eliminated because you can select the optimal well—whether producing or not—for interception of the primary reservoir target to produce. This value is also seen for offshore subsea developments, in addition to the elimination of procuring and installing the associated subsea infrastructure.

| TAML 2 | TAML 3 | TAML 4 | TAML 5 | |

| 7-in casing | RapidAccess; RapidMSS |

RapidTieBack |

RapidTieBack | RapidX |

| 9 5/8-in casing | RapidAccess | RapidXtreme | RapidXtreme | RapidXtreme; RapidX |

| 10 3/4-in casing | None | None | None | RapidX |

RapidX TAML Level 5 junctions connect 31 laterals to only 13 wellheads, maximizing reservoir contact while reducing opex and capex

Read case study