Monoline

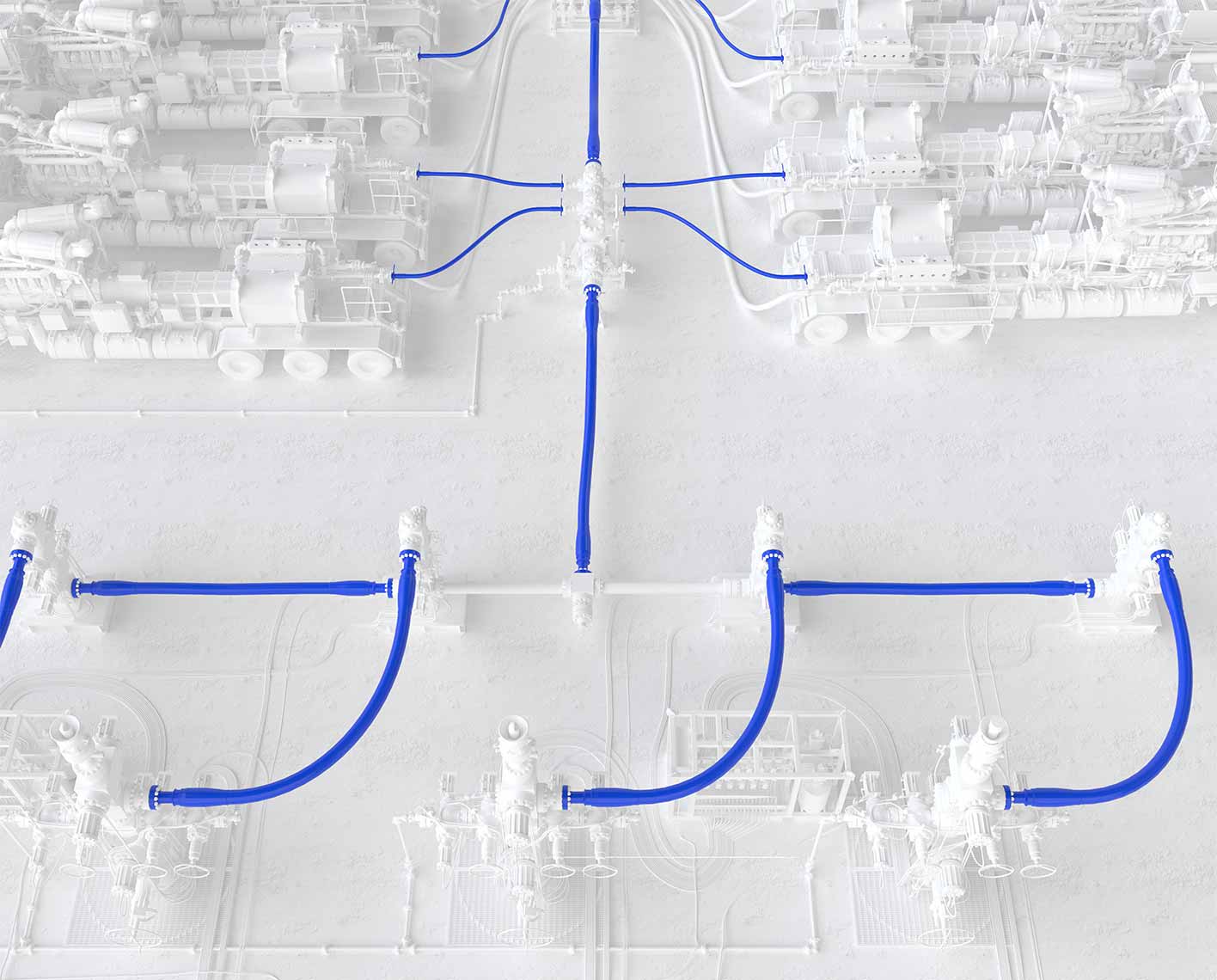

Flanged-connection fracturing fluid delivery technology

API 6A flanged connections provide reliable frac fluid delivery

MonoFlex™ dual-connection fracturing fluid delivery technology speeds up multiwell pad rig-up, reduces NPT, and limits HSE risks with a flexible, erosion-resistant conduit that can be used on any part of the fracturing fluid delivery system.

MonoFlex technology has been proven in field applications since 2017. By simplifying flow paths and minimizing the number of connections and flowlines, the technology has streamlined operations and optimized proppant and fracturing fluid delivery in more than 2,000 wells across North America.

Available to oil and gas operators and service companies, the technology has been used to connect

over 7,000

Wells treated200 MM

lbm of sand delivered through one line100

bbl/min average pump rate for 5-in sizeVarious bore sizes with 15,000-psi [103.4-MPa] maximum working pressure and temperature range from –40 to 158 degF [–40 to 70 degC].

| Nominal Diameter, in | 2 | 2.7 | 3 | 4 | 5 | 6 |

| Max. injection rate, bbl/min [m3/min] | 13 [2.1] | 24 [3.8] | 30 [4.8] | 65 [10.3] | 110 [17.5] | 160 [25.4] |

The following SLB products are protected by patents in the U.S. and elsewhere. This website is provided to satisfy the virtual patent marking provisions of various jurisdictions including the virtual patent marking provisions of the America Invents Act. The following list of SLB products may not be all inclusive, and other SLB products not listed here may be protected by one or more patents.

MonoFlex™ Dual-connection fracturing fluid delivery technology: Protected by U.S. Patents 8,839,867; 8,978,763; 9,222,345; 9,255,469; 9,903,190; 9,915,132; 10,132,146; 10,323,475; 10,385,662; 10,787,879; 10,934,816; 10,487,637; 9,068,450; 9,518,430; 11,162,320; 11,391,109; 10,480,300; 11,066,913; 11,434,739; 11,828,148; 11,015,413; 11,898,411; 11,319,757; 11,725,460; 11,885,207. Additional patents may be pending in the U.S. and elsewhere.