Suppressor flex dampening tool

Eliminates the need for additional tools and connections within the BHA

High-frequency torsional dampening flex sub designed to improve efficiency without impacting BHA design.

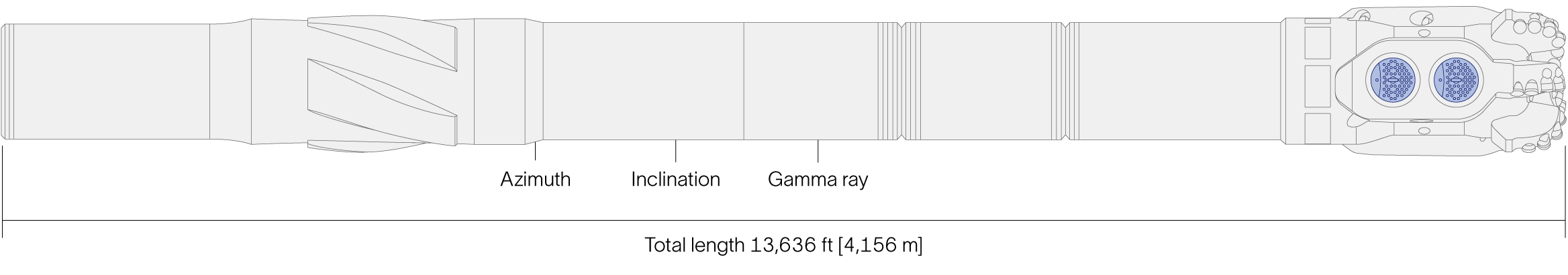

The NeoSteer CLx™ extreme curve and lateral at-bit steerable system (ABSS) is designed to enable drilling the curve and lateral in a single run. This innovative system empowers operators to attain exceptional build rates and elongate lateral lengths within unconventional drilling applications. In scenarios where the hole size does not change across the vertical, curve, and lateral sections, the NeoSteer CLx system reduces NPT by eliminating the need to change out the BHA for every section.

The NeoSteer CLx system includes comprehensive six-axis continuous inclination and azimuth measurements. This multiaxial feature enables automatic high inclination angle (HIA) capability, ensuring accuracy during drilling. Combined with self-steering capabilities and closed-loop automation, it helps provide smooth tangents with minimal tortuosity. Near-bit extended-range gamma ray measurements deliver enhanced real-time decision making by providing supplementary well positioning data.

The NeoSteer CLx system uses an actuating system to exert pressure against the borehole wall for propulsion. The fully integrated pistons enhance curvature leverage within the cutting structure. It uses this leverage to achieve higher build rates without requiring additional hydraulic force. This enables the system to meet both the curvature requirements in the curve section and the directional control needs in the lateral section effectively. Its steering unit incorporates metal-to-metal hydraulic seals to minimize erosion and enhance hydraulic design capacity for improved performance. When configured within a motor-assisted BHA, the NeoSteer CLx system can achieve speeds of up to 350 rpm, ensuring precise directional control and reliable steerability.