Drill through a narrow 0.5-lbm/galUS window limited by wellbore

instability and the risk of differential sticking

Repsol experienced a number of challenges while drilling the production

section of its highly deviated Sagari wells in Peru. The succession of

high-permeability, low-pressure sand reservoirs presented a high risk for

losses and differential sticking. The operation also required drilling through

the highly mechanically unstable interbedded Shinai Formation. In addition,

naturally fractured dolomite leads to low ROP and risk of severe losses. In one

well, with a narrow 0.5 lbm/galUS operating window, Repsol sought an automated

MPD solution that would enable nearly constant bottomhole pressure, mitigating

the risk of wellbore instability and high ECDs that can induce losses and

differential sticking.

Minimize pressure variations and sustain ECD

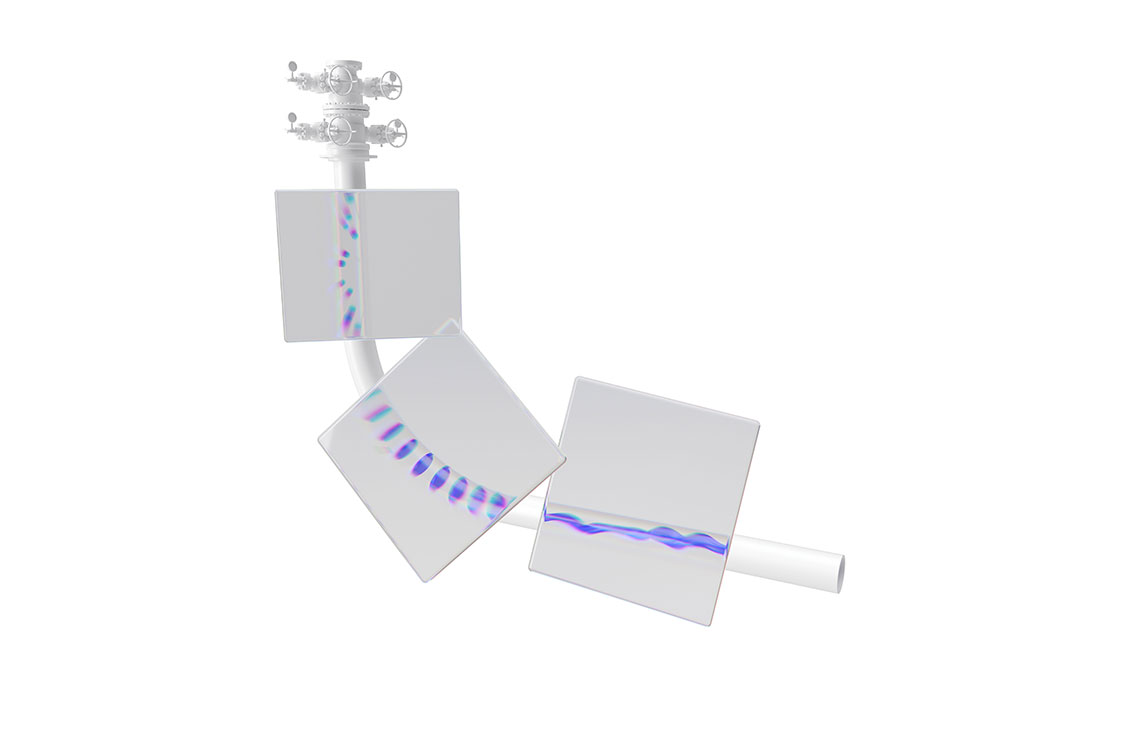

M-I SWACO recommended a mud weight of 9.2 lbm/galUS along with the

@balance Control MPD system. The system’s small footprint enabled

streamlined transportation via helicopter to the remote jungle rig site and

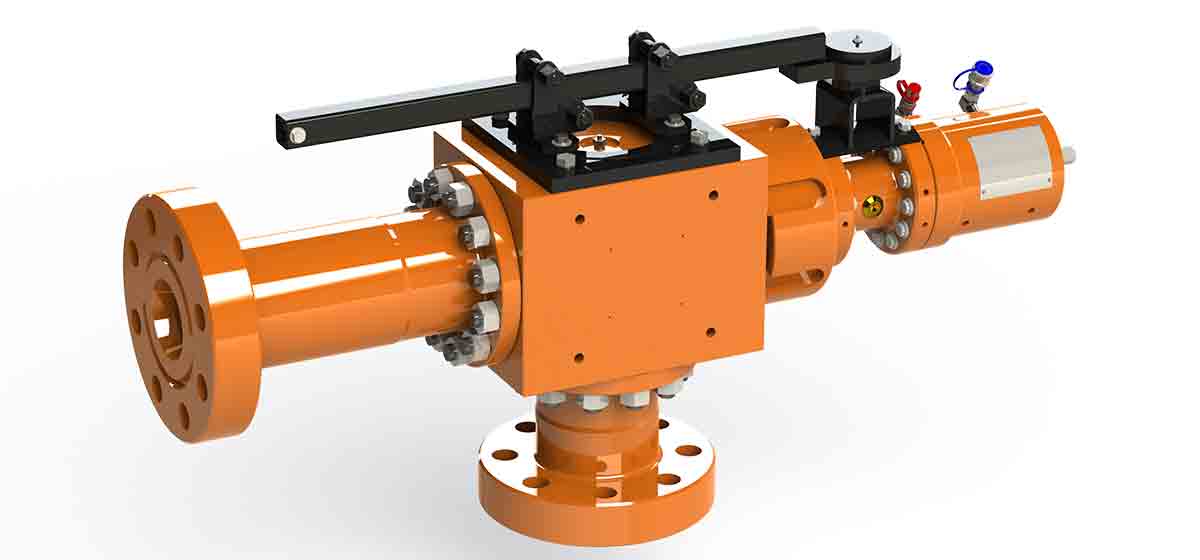

rigged up in less than 15 hours. The package included a HOLD remotely operated

annular control device with a dual-sealing element assembly, 41/16 in automated

choke manifold with two VERSA-CHOKE modular drilling choke technologies,

backpressure pump, flowmeter to serve as an early kick detection system,

piping, and human machine interface.

The RCD together with the sealing elements sealed the annular space and

deviated the drilling fluids coming out of the annulus toward the MPD choke,

permitting the application of surface backpressure as necessary. Real-time

hydraulics software adjusted surface backpressure automatically to changing

drilling parameters. The backpressure pump enabled better control of the

applied surface backpressure during connections and while tripping without

circulation. It maintained the flow of drilling fluid through the chokes when

the rig pumps were off, keeping the well full of drilling fluid at all times.

The flowmeter that was placed downstream of the MPD choke provided early

indication of fluid losses or influx by precisely monitoring small

discrepancies between flow in and flow out.

Repsol used @balance services to drill three production sections in two

wells in the same location. Additionally, managed pressure cementing (MPC) was

used in the intermediate casing and production liner in the last well.

Mitigated risk of wellbore instability, fluid losses, and differential

sticking

The MPD strategy was based on a geomechanical model and on past

experience from offset wells. In the planning phase, comprehensive hydraulic

simulations were performed with VIRTUAL HYDRAULICS drilling fluid simulation

software and Drillbench dynamic drilling simulation software to predict the

pressure profile along the wellbore in different operational phases, such as

drilling, tripping in and out, and performing mud rollovers. The impact of

parameter variations—including mud density, rheology, ROP, pipe rpm,

bottomhole temperature, and bottomhole assembly design on the pressure

profile—was studied to design the MPD strategy and make recommendations,

mitigating riskthroughout the job. The MPD strategy evolved from well to well

based on lessons to optimize the MPD strategy for drilling the challenging

production section in Sagari field.