Manage or shut off water and gas production with application-specific permeability modifiers, chemical blocks, or cements.

Increase Oil Production Without Increasing Water Cut in Ecuador

Published: 03/01/2011

Increase Oil Production Without Increasing Water Cut in Ecuador

Published: 03/01/2011

Stimulating oil intervals and diverting from water zone

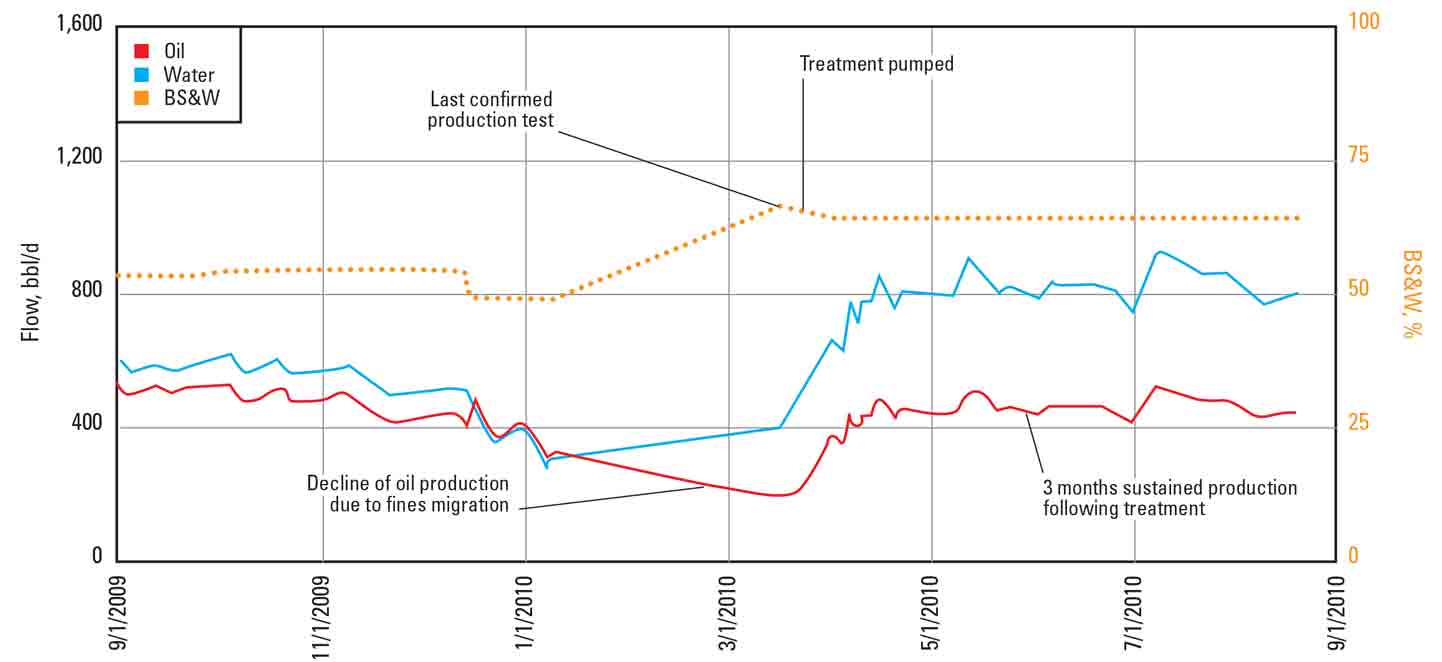

PetroEcuador, the Ecuadorean national oil company, produces from the Napo "U" Inferior sandstone formation in the Shushufindi field with permeability ranging from 90 to 300 mD. Pressure support from a lateral aquifer results in increasing water production with time. In September 2008, water broke through in the high permeability intervals in a well producing 500 bbl/d of oil, with 60% water cut.

Oil production then decreased to 200 bbl/d. This production decline was the result of a high drawdown, the onset of water production, and the high clay content—including kaolinite— in the formation. The primary damage mechanism was identified as fines migration, a common problem in Ecuador. This was in addition to an emulsion caused by completion fluids during a previous workover.

Engineered solution

A treatment was needed to remove the damage in the intervals producing oil and “good” water without stimulating the interval where water had already broken through. Schlumberger proposed the following treatment:

- brine with mutual solvent and de-emulsifier to break the emulsion

- OilMax treatment to divert away from intervals with high water cut and high permeability streaks

- acetic acid preflush and OCA LT organic clay acid main treatment fluid to remove the damage caused by fines migration

The stimulation treatment using OilMAX diverter enabled the treatment to be diverted to the intervals where water had not broken through. A nodal analysis model predicted that the well had a skin of approximately 10 prior to the treatment, and this skin was reduced to nearly zero after the treatment. The production level after the treatment is stable after more than 5 months with no increase in water cut, indicating that the stimulation treatment was successful in stabilizing the clays and limiting water production.

Achieving sustained production increase

After the treatment, oil production increased from 200 to 500 bbl/d with no change in the water cut. The OilMAX diverter, successfully diverting the stimulation fluid away from the intervals with high water cut, allowed it to successfully stimulate the oil-producing intervals.

Challenge: Increase oil production in a well with a high water cut, without increasing the water cut.

Solution: Use a matrix stimulation treatment combining organic clay acid (OCA) and OilMAX diversion and conformance control to maximize zonal coverage and minimize water production.

Results: Doubled production. Sustained production increase with same water cut as pre-treatment.