Manage or shut off water and gas production with application-specific permeability modifiers, chemical blocks, or cements.

Bolivian Operator Uses High-Performance Acid System to Increase Mature Well Production 400%

Published: 08/01/2012

Bolivian Operator Uses High-Performance Acid System to Increase Mature Well Production 400%

Published: 08/01/2012

Operator wanted to increase sustained production in mature sandstone formation

YPFB Andina, one of Bolivia’s main operators, conducted several studies and tests aimed at optimizing production from its oil fields and increasing Bolivian oil production overall. YPFB Andina selected the Los Penocos (LPS) field, which produces mainly from the Petaca formation.

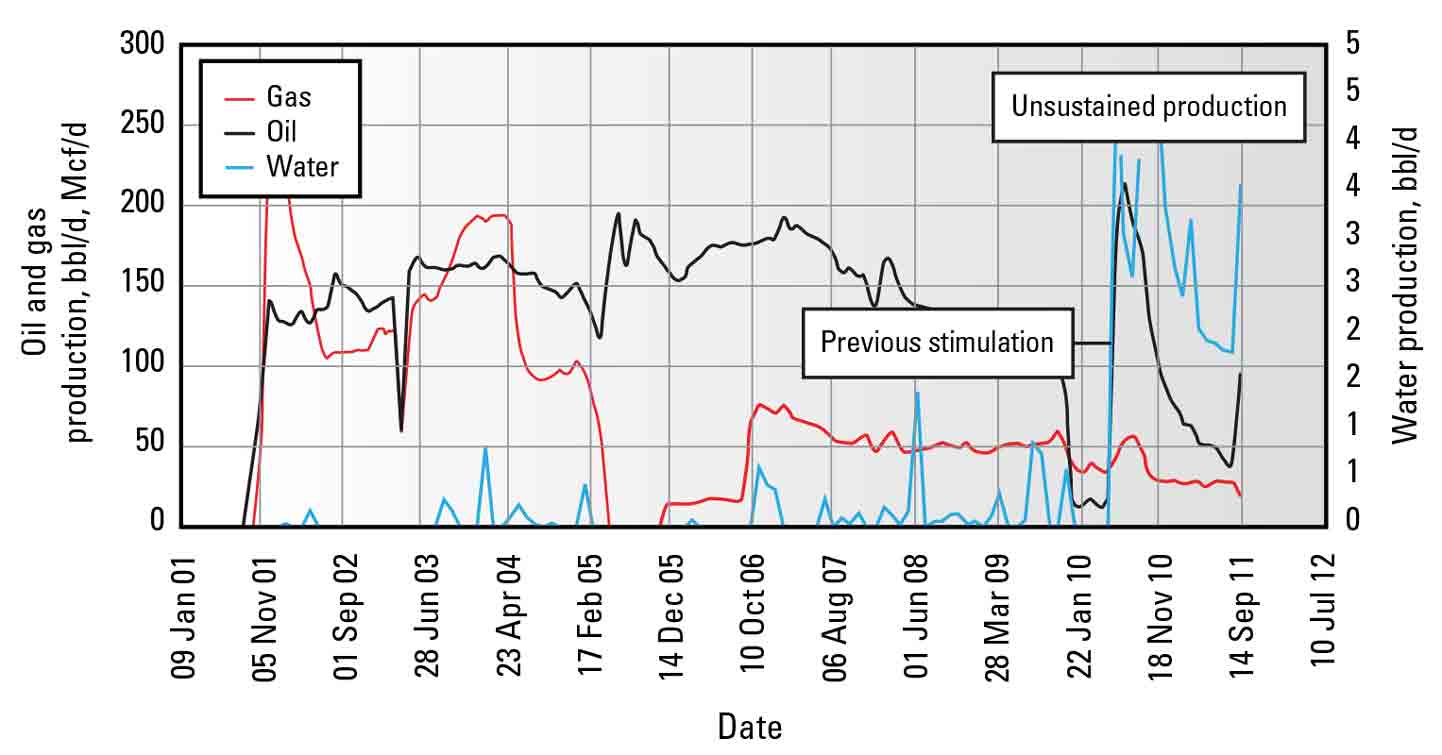

The field has been producing since 2001, and its wells have been completed with gravel packs because of the unconsolidated sands. YPFB Andina has focused on reactivating this mature field while searching for a recompletion strategy designed to stimulate the Petaca formation through matrix treatments. Several stimulation attempts were made in the Los Penocos, but they proved unsuccessful because of unsustained post-treatment production.

YPFB Andina applied enhanced recovery system

Production from the reservoir has been historically unstable with a constant drop in the production rate since 2006. As a result, the YPFB Andina production and development engineering team proposed using a gas-lift system with a packoff and calibrated valves conveyed on slickline. Well production reached 200 bbl/d for 2 months but declined sharply. The well was then cleaned with an acid system. Production increased to initial rates but declined again after 1 year (Fig. 1).

After performing an overall well history analysis, the team concluded that well performance was affected by the reduced diameter of packoff pipes due to the presence of paraffin and fines. Therefore, they decided to replace the gas-lift system with a packoff by a conventional gas-lift mandrel array. Production was restored but quickly declined.

Schlumberger recommended OCA fluid system to stimulate matrix and stabilize fines

Owing to the repeated negative results, the engineering team decided to commission Schlumberger to perform a full stimulation study.

Schlumberger recommended a CT-conveyed matrix acid treatment with nitrogen to clean the well. Based on the formation damage characterization analysis, the proposal included CLEAN SWEEP solvent systems, hydrochloric acid, and OCA fluid as the primary treatment. OilSEEKER acid diverter was required due to the interval length. Nitrified fluids were recommended to promote well cleanup following treatment.

YPFB Andina increased sustained oil production 400%, broadened project scope

Production results after the treatment were above average levels compared to historical data. After stimulation, production reached 265 bbl/d, a dramatic four-fold increase compared with production before treatment in the subject well (Fig. 2). In addition, the treatment delivered a sustained production for more than 2 months, which had not been achieved with previous treatments applied in the same well.

NODAL analysis, based on data provided by YPFB Andina, is shown in Fig. 3. The well yielded a 400% sustained production increase compared with initial production.

Challenge: Increase sustained production in unconsolidated sandstone formation by

- cleaning up wellbore damage

- stabilizing fines

- achieving deep, live-acid penetration

Solution: Perform matrix acidizing treatment with OCA fluid and OilSEEKER acid diverter to increase estimated ultimate recovery while minimizing risk of precipitation, corrosion, and fines migration.

Results: Improved sustained production from stimulated wells by 400% compared with previous treatments and offset wells.