Carbon capture

Differentiated technologies and expertise to optimize your carbon capture and lower costs

Accelerate decarbonization—starting with carbon capture

CO2 is rarely accessible as a standalone molecule to capture and store underground. Instead, it’s usually mixed with other gases produced in industrial processes. So, the ability to capture CO2 from different effluent gas streams is key. Additional challenges include high energy consumption, complex systems integration, infrastructure footprint, and the handling of contamination in gas streams—all resulting in higher capex and opex.

Leveraging our expertise, SLB is building a broad and highly differentiated carbon capture portfolio that covers a wide range of emissions streams. This includes solutions across a broad variety of industrial emissions and those for typically hard-to-abate and dilute CO2 streams. Through our technology leadership and unique commercial models, we improve your capture performance while lowering costs.

A market-ready portfolio of solutions

SLB Capturi combines technology portfolios, expertise, and operations platforms to accelerate carbon capture adoption for industrial decarbonization at scale. Through this joint venture, we will apply advanced carbon capture solutions across a broad range of industrial sectors—from cement and steel manufacturing to coal and gas power generation, chemicals, and hydrogen.

Our portfolio of technologies includes amine-based Advanced Carbon Capture™ technologies, Just Catch™ and Big Catch™ modular plant technologies for medium- and large-scale facilities, and Just Catch Offshore™ for offshore gas turbines, as well as a portfolio of innovative technology solutions, including non-aqueous solvent and emerging sorbent-based offerings.

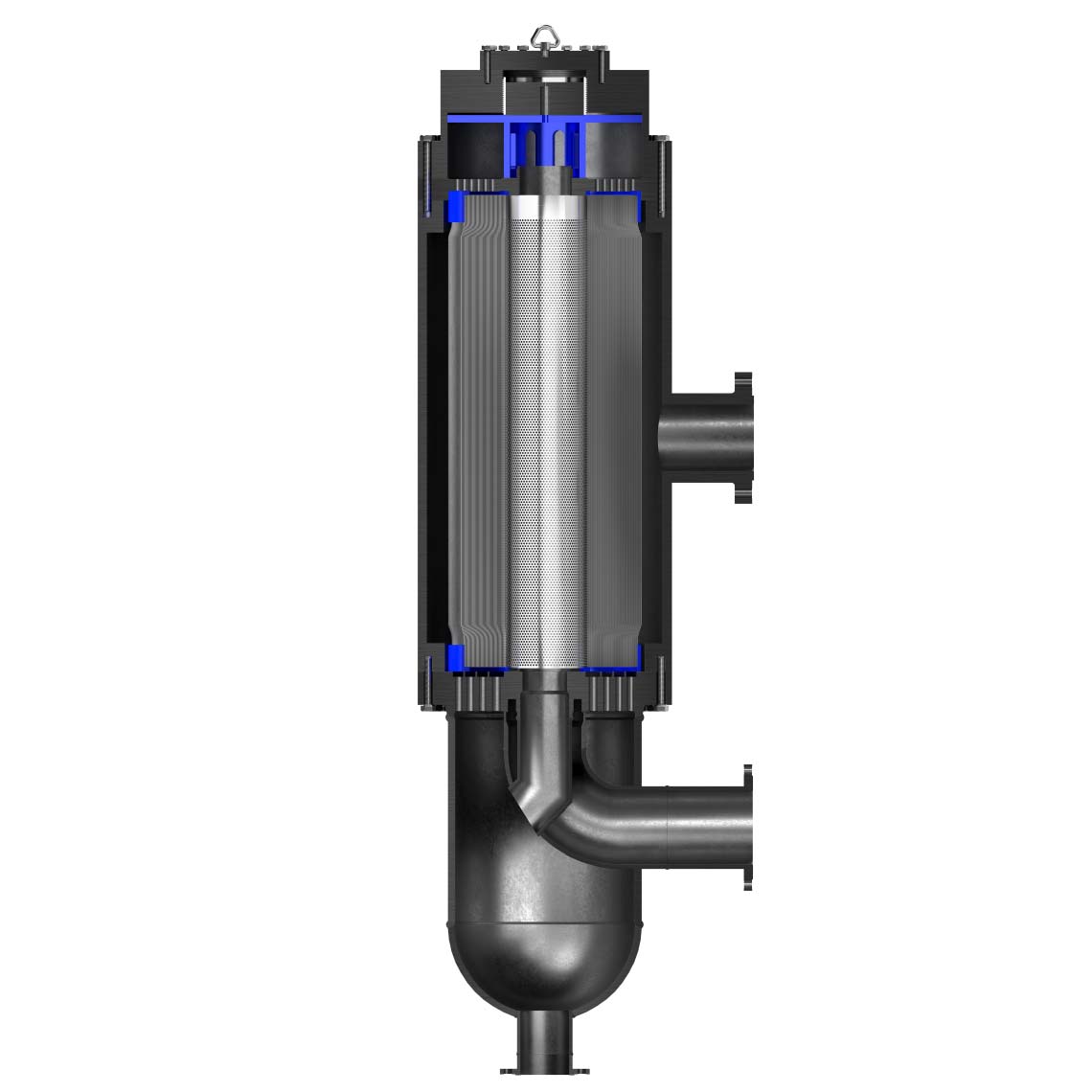

Leading CO2 capture from natural gas

SLB has been removing CO2 from natural gas streams since the early 1980s with our Cynara H2S and CO2 separation membranes. Cynara membranes have a proprietary membrane design with the most efficient surface area in the market, which is critical for scaling CO2 separation and capture. This provides higher-efficiency CO2 separation without chemicals, reducing cost and environmental impact while delivering a track record of 99% uptime. Cynara membranes also reduce embodied carbon by up to 50% compared with alternative methods of acid gas removal and minimize emissions by 30% to 50% when compared with amine sweetening.

The higher hydrocarbon retention from Cynara membranes versus alternative membranes enables CCUS for high-purity CO2 outlet streams, further reducing emissions intensity.

99%

Up to 50%

30%–50%

Dive deeper

-

Carbon Sequestration

Integrated solutions for selecting, planning, constructing, operating, and monitoring carbon storage sites.

-

The Vital Role of CCUS

SLB’s bold approach to a practical and viable carbon abatement solution.

-

Carbon Capture and Processing

Processing systems knowledge and intelligent software to help determine the capture technology fit for you.

-

Carbon Transport

On the road to reducing emissions, choose transport solutions you can count onCaptured carbon only goes as far as delivering it with the highest safety and optimization in mind.

Fundamental carbon capture and sequestration for managers

This virtual course will familiarize management personnel across industries about CCUS. Topics include a discussion on the global outlook for CCUS, integrated workflows for projects, key technologies, case studies, and more.

The vital role of CCUS and SLB’s involvement

Watch as our SLB experts discuss the challenges facing the CCUS industry and how we’re poised to ensure your project’s success.

Carbon capture and sequestration—a rapidly growing industry

This webinar discusses the critical stages to planning and implementing successful CCUS projects. It also presents case studies and talks about how SLB evolved its technology portfolio to support CCUS.

Featured products and services

-

Implementation-Ready Capture Platform

SLB and Aker Carbon Capture joint ventureTechnology solutions for mid-range to large-scale industrial emissions streams.

-

Carbon Capture, Utilization & Sequestration

We have the tech, talent, and experience to take on your biggest carbon challenges—all in one placeCombining subsurface and surface expertise and technologies for an end-to-end partnership you can count on.

-

Cynara

H2S and CO2 separation membranesSeparate acid gases from produced natural gas without chemicals.

-

Amine Gas Treating Systems

Standard and customized gas-treating designsPrepare natural gas for transport and use by removing CO2, H2S, and mercaptans.

-

ChampionX production chemicals and services

Maximize production from reservoir to refineryImprove and assure production more safely with chemistry technologies, software, and mechanical solutions.

-

Symmetry process simulation software

Improve safety, profits, and performance by optimizing process workflows in one platform.Improve safety, profits, and performance by optimizing process workflows in one platform.

-

Olga dynamic multiphase flow simulator

The industry-standard tool for dynamic multiphase flow simulationThe industry-standard tool for dynamic multiphase flow simulation.

SLB Carbon Capture and Sequestration

Accelerate your path to net zero with flexible, reliable, collaborative, and cost-effective solutions across the CCUS value chain.

Explore more