Physics-Informed AI

Simulation-quality insight with the speed and flexibility of AI

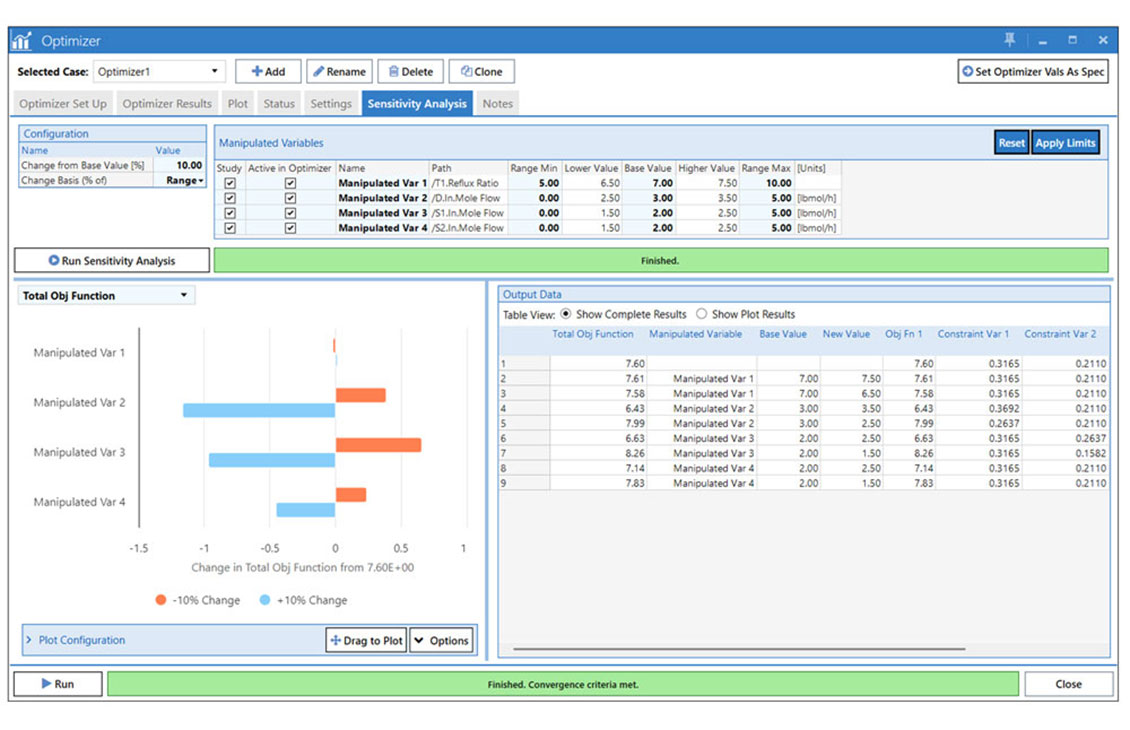

Physics-informed AI is a breakthrough hybrid model building technique, that fuses physics-based simulation and process data.

The Symmetry™ process simulation software offers a unique opportunity to model your process workflows in one environment, integrating facilities, process units (Symmetry Process) with pipelines, networks (Symmetry Pipe) and flare, safety systems (Symmetry Flare) models, while ensuring consistent thermodynamics and fluid characterization across the full system. This approach enables companies to optimize processes in upstream, midstream and downstream sectors, maximizing profits and minimizing CAPEX.

Symmetry software empowers teams across the full life cycle of process modeling—from initial conceptualization to detailed engineering and design, through commissioning and startup and into operations. It supports continuous improvement by helping maximize reliability and availability, reducing emissions and energy consumption, and optimizing economic performance. With its integrated workflows and advanced simulation capabilities, Symmetry software enables smarter decisions and more efficient operations at every stage.

Model inflow and flow assurance workflows, predict and manage pigging and slugging, forecast field production rates, model gathering systems and pipeline networks.

Optimize gas processing, oil and heavy oil processing, LNG and gas-to-liquids conversion, and utilities management, including steam and power generation.

Optimize oil refining, petrochemical and production, and alternative technologies such as fuel cells and gasification.

Feasibility, concept selection and detailed design for transition and alternative technologies including geothermal, hydrogen, energy storage, and carbon capture.

Establish baseline performance and evaluate different options for reducing emissions, including reduced routine flaring, alternatives to flaring, fuel gas minimization through energy management, and feedstock management (hydrogen or bio-feed blending).

Applying total site energy management supports the reduction in energy consumption in facilities at all scales, from rotating equipment to entire plants. Applications are as varied as reducing fuel consumption, power generation from waste heat (energy integration), and optimizing the application of renewable power.

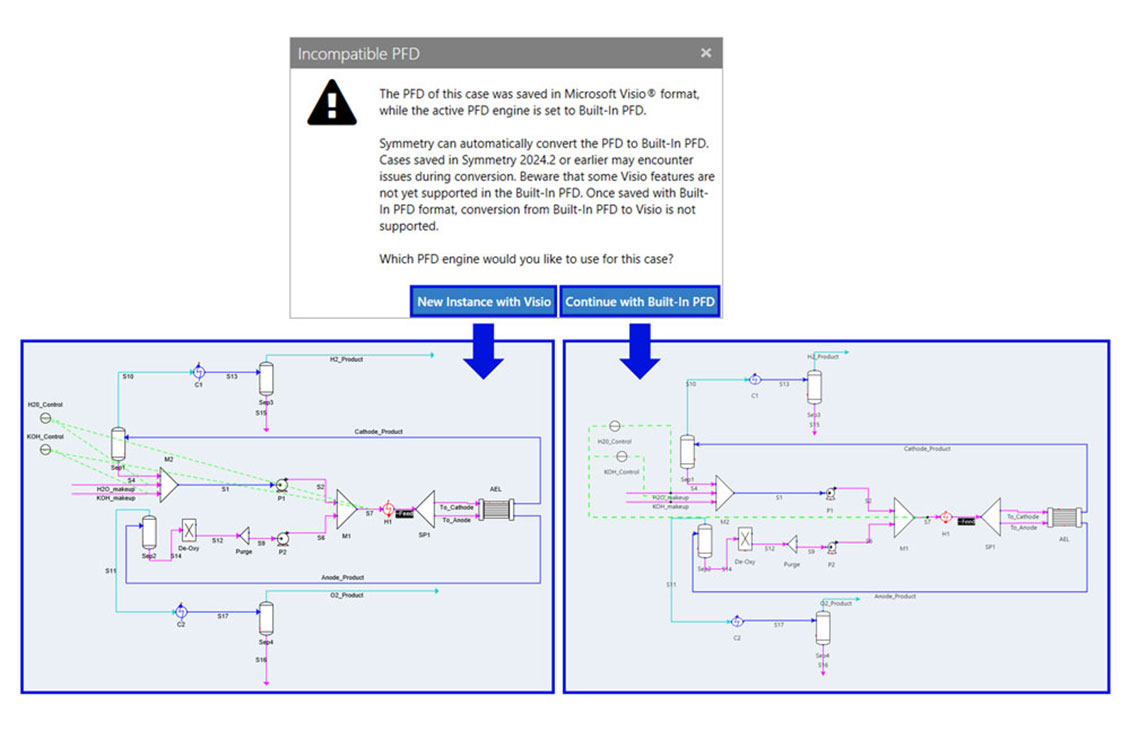

Symmetry software enables you to model process workflows in a single integrated environment, with accurate thermodynamic fluid representation and consistent modeling across all disciplines including process, production, and HSE. The simulator integrates steady-state and transient (dynamic) analyses that can be tailored for each domain. This approach enables companies to optimize processes in upstream, midstream, and downstream sectors while maximizing profits and minimizing capital expenditures. Offered as one of SLB's Transition Technologies, Symmetry software can help reduce emissions, energy consumption, and waste.

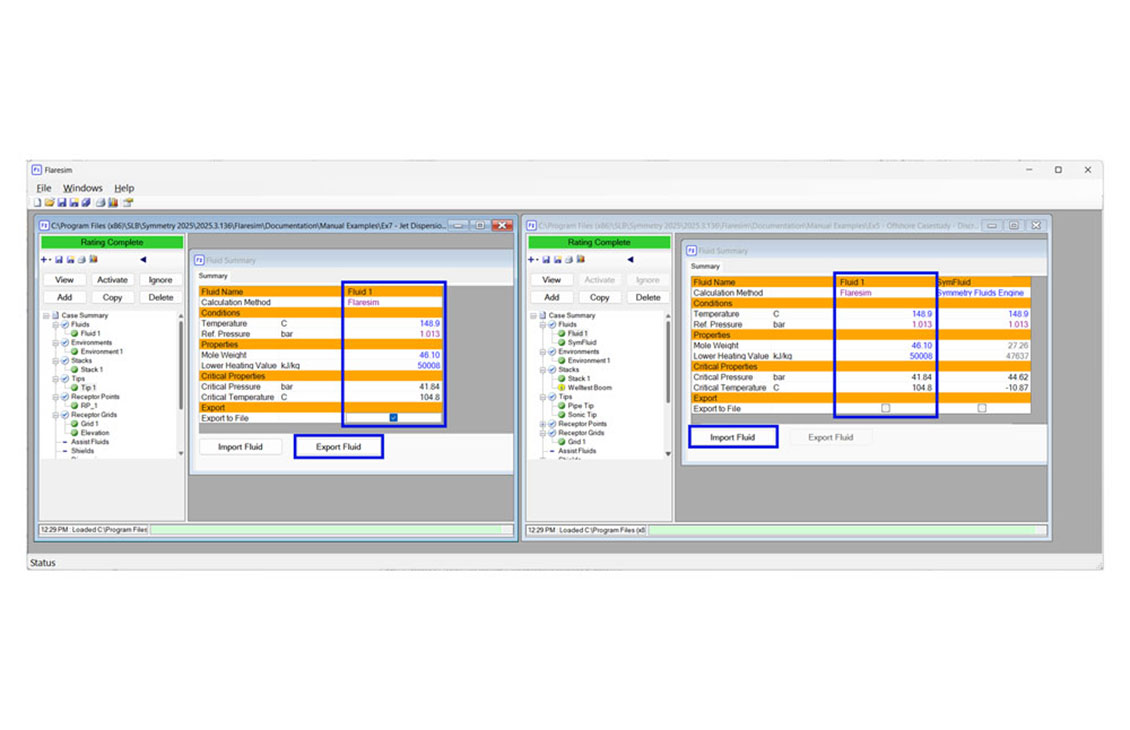

Characterize fluid with a best-in-class approach

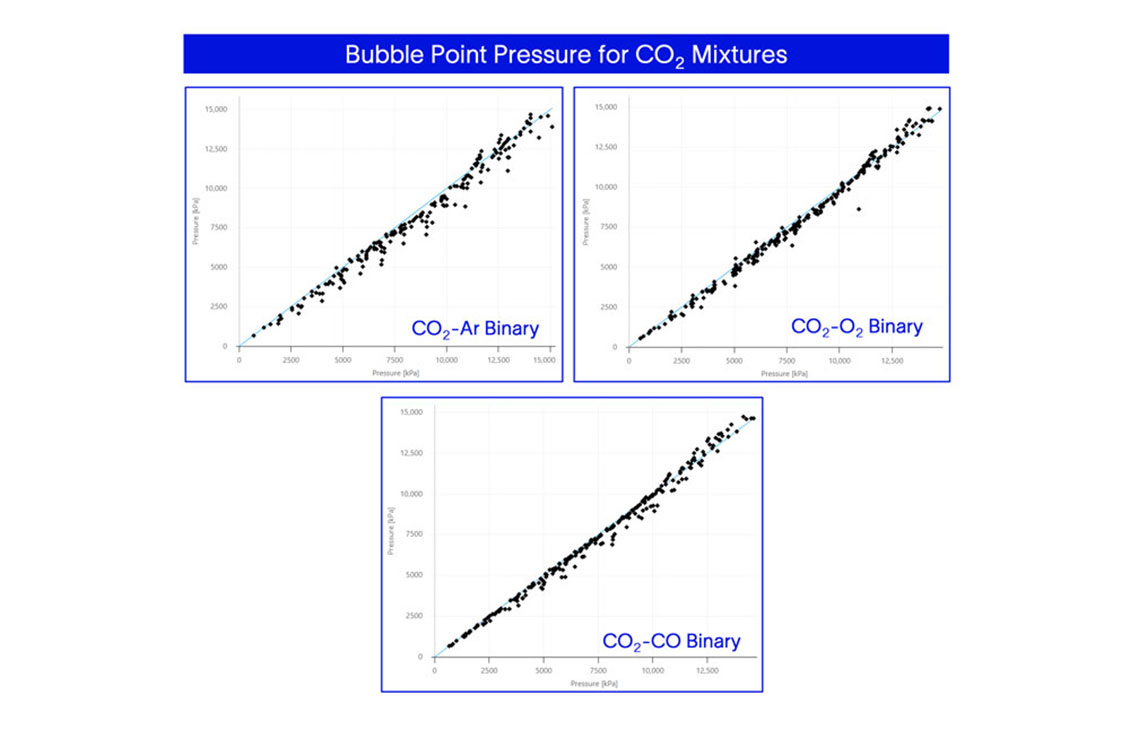

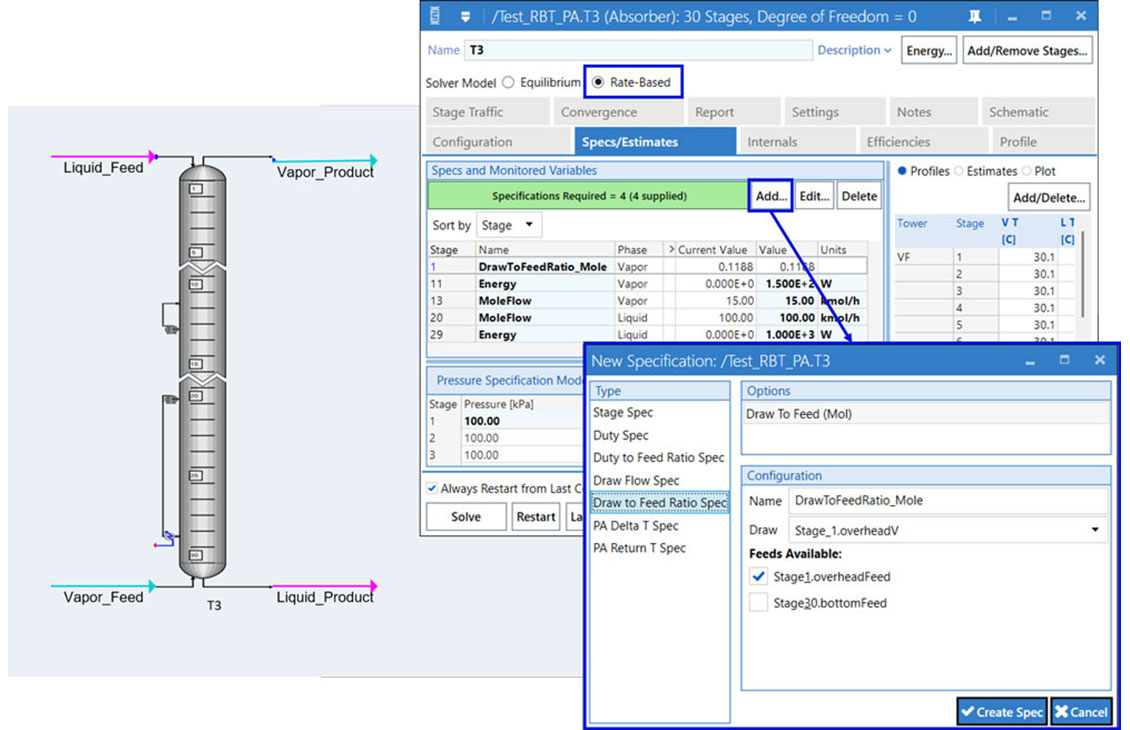

Symmetry software is powered by a best-in-class thermodynamic engine used for fluid representation, which is extensively validated against experimental data. The built-in database includes more than 20,000 chemicals, 80 thermodynamic property packages, and hundreds of unit operations, providing unparalleled model sophistication and precision.

The software uses a PIONA approach to model hydrocarbons, enabling process engineers to accurately simulate blending, separation, and even reactive systems. This molecular approach can accurately model the formation of hydrates, wax, and asphaltene and can accurately simulate hydrocarbon mixtures coming from different fields. The behavior of hydrate inhibitors is also accurately represented.

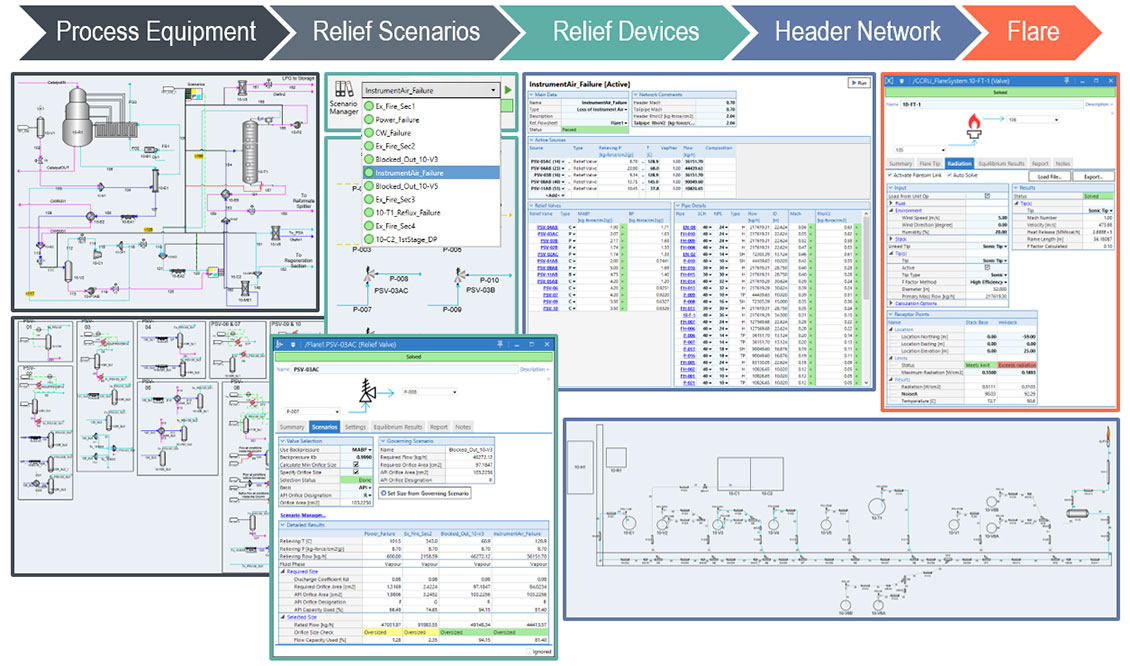

Comprehensive identification of specific safety concerns, from fire scenarios to equipment failures and much more, is an essential element of all operations. To enabling the mitigation of HSE and operational risks, Symmetry software provides a complete set of flare and relief system design tools that empowers users to verify the performance of entire safety systems.

The software is flexible enough to suit any application, analyzing standalone components or complete system with various levels of detail, in steady state or dynamics.

Symmetry software enables full life cycle modeling from conception to operation, which provides better options to troubleshoot performance, create FEED and start up studies, and fully optimize your system. The software offers extensive options to provide openness such as COM, OPC connectivity, CAPE open, custom interfaces and more, to enable integration with different systems, helping you fully understand your asset.

Symmetry software provides a new approach to traditional oil pseudo-component characterization techniques. Its PIONA-based fluid characterization uses chemical family structures to enable accurate physical property estimation in blending, separation, and even reactive systems to be more accurately simulated. Ensuring consistent thermodynamics and component tracking across the full system.

Symmetry software provides additional competitive advantage by leveraging the Delfi™ digital platform. This provides access to more than 20 years of deep science across the spectrum, and the ability to utilize advanced AI techniques.

NExT offers a comprehensive training program to support users of the SLB software, plugins, and other software products.

Reducing software costs and making dynamic simulation affordable to companies in the process industries.

Symmetry Field Workspace models large and small gas properties.

The Flare workspace empowers users to verify safety systems completely, efficiently, and rigorously.

Integrated approach to optimize production.

Advancing process understanding.

An extensively validated thermodynamics library with almost 20 years of program refinement.

Market-leading technologies integrated in the cloud focused on key domain user profiles.

Learn more