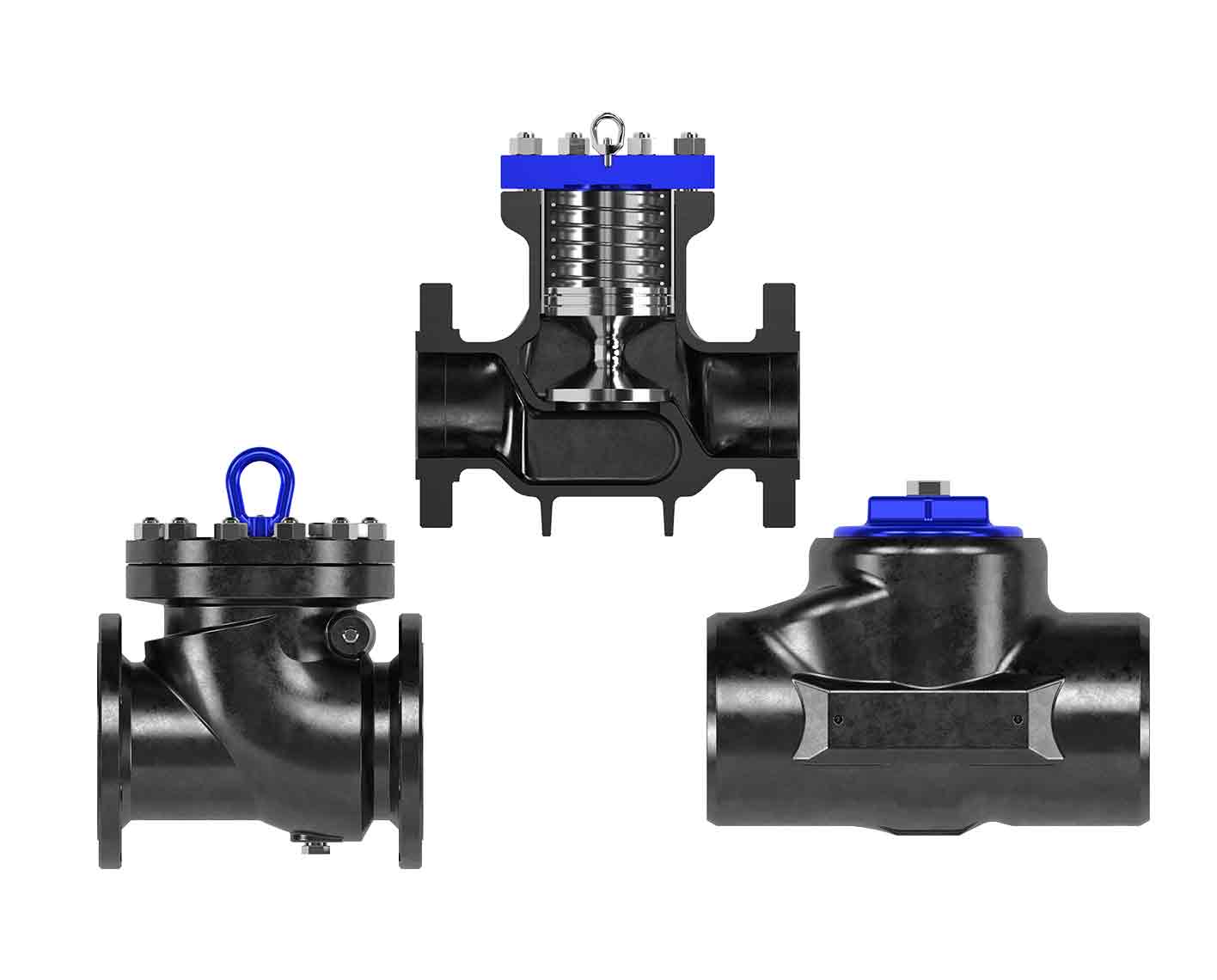

Check valves

Reliable fit-for-purpose flow control solutions with ease of access and low maintenance

Flow control solutions that eliminate backflow

Check valves have long been a cornerstone of the energy industry because of their reliability and proven performance in sealing tightly to prevent reverse flow. Our portfolio includes valves for a wide variety of high- and low-pressure applications where backflow prevention is critical, including reciprocating pumps and compressors; renewable fuels, hydrogen, and CCUS service; gas compressor stations, storage, and processing stations; and exploration and development drilling on land.

Benefits of top-entry valve design

Featuring robust top-entry designs, our check valves perform reliably with low maintenance requirements. Top entry means that maintenance tasks are completed more easily and quickly, reducing both downtime and cost of ownership.

Tom Wheatley™ piston check valves

Especially effective in scenarios with pressure surges and pulsating flow, such as gas compressor station discharges

Wheatley™ series 822 and series 500 check valves

Designed to protect pumps by preventing backflow over years of trouble-free service

Tom Wheatley swing check valves

API Spec 6D–compliant, fullbore pipeline swing check valves for demanding environments

Entech™ nozzle check valve models DRV-Z and DRV-BN

Modular design and maintenance-free, nonslamming, quick-close performance for liquid and gas compressor and pumping stations (suction and discharge)