Low-emission valves

Trust our API- and ISO-certified Low-E valves to mitigate fugitive emissions in your operations

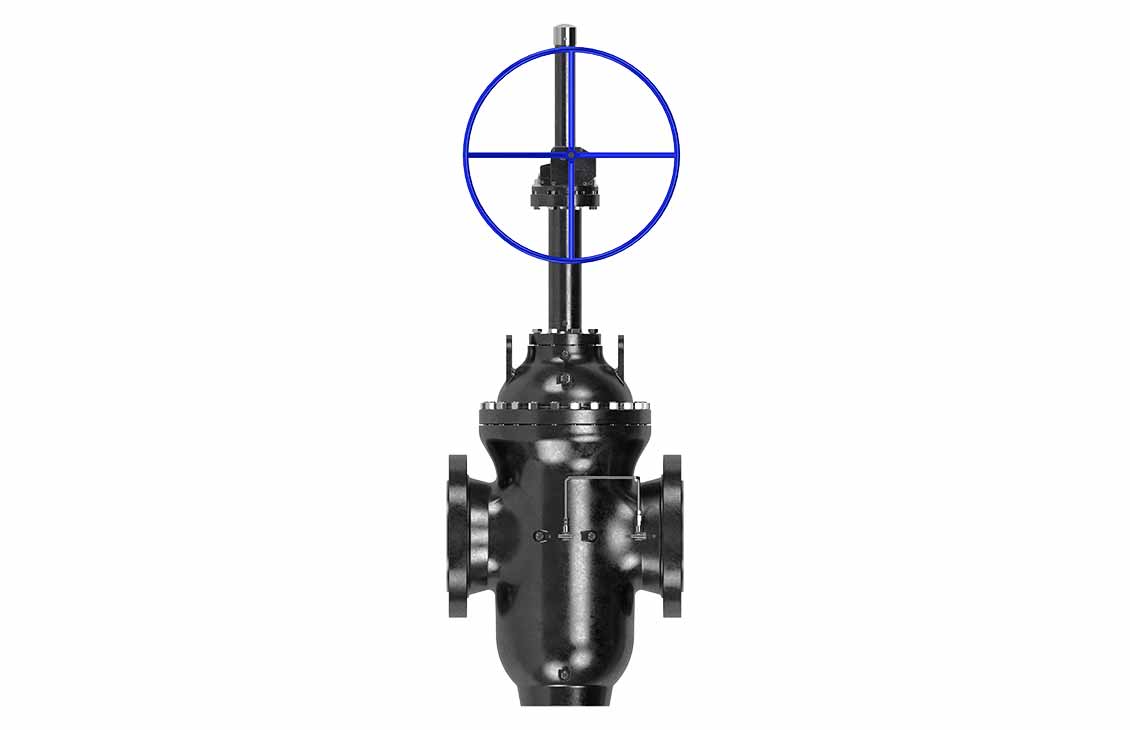

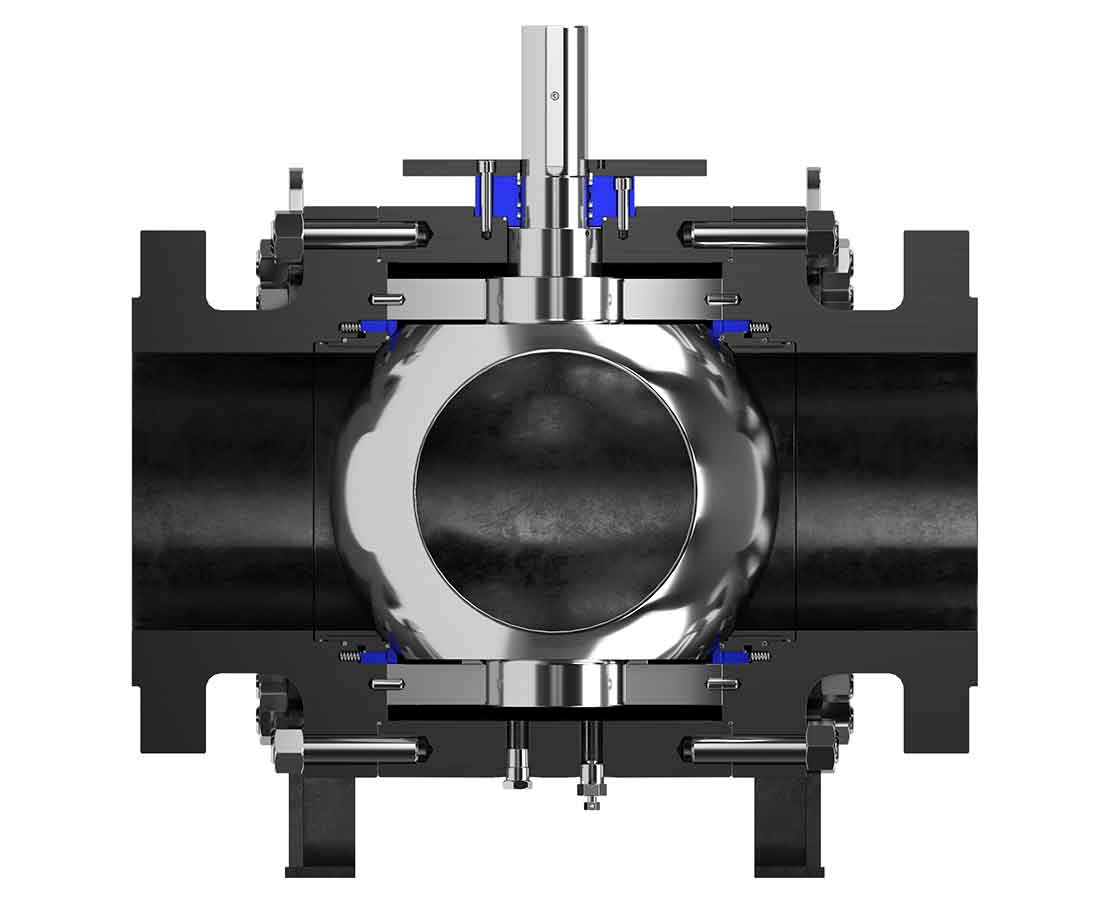

Our portfolio of fugitive emissions– (FE-) compliant valves, also called Low-E valves, includes traditional, well-known ball valve types—trunnion-mounted, floating, and rising stem—together with gate valves, plug valves, and new technology, such as the integrated-seat ball valve. Certified to industry FE design standards API 624 and 641 and ISO 15848-1, these valves have a wide range of applications, including gas processing plants, LNG plants, refineries, petrochemical plants, oil and gas production, and pipelines.

Emissions reduction

Low-E valve packing can provide up to 96% reduction in emissions relative to standard packing.

Minimize greenhouse gas emissions in upstream, midstream, and downstream valve applications

Low-E valves are an integral part of emissions reduction strategies across any industry. This is because valves contribute significantly to the number of joint and pressure boundary penetrations in a pressure-containing system and are therefore, potential sources of emissions.

Qualifying valves to relevant industry standards can help assure that emissions from pressure boundary penetrations are minimized to acceptable levels. Our Low-E valves meet global emissions standards across their full life cycle, using technology you’ve trusted for 50 years—now enhanced to address the challenges of today and tomorrow. Current standards qualify against methane emissions. However, SLB provides FE-certified valves that can also be used for services involving hydrogen (provided the valves undergo helium testing), CO2, and other greenhouse gases, in addition to methane.

The right valve, maintained optimally

Selecting the right valve technologies and maintaining them properly is the best way to minimize or prevent fugitive emissions. Targeting these emissions presents a low-risk, high-yield opportunity to reduce your environmental impact. Our valve technology and OEM maintenance services and support deliver long-term value and help you maintain your social license to operate.

Whether you have an existing installation or are working on a new project, our experts can walk you through available valve types and testing, certification, monitoring, and maintenance options so that you can install what you need and keep it operational for years to come.

Services to maintain and monitor valve performance

Maintenance of certification

Any deviation from the valve parameters, such as tolerances, finishes, seal material, and grade, that results from valve servicing and repair renders the original certification invalid and provides no guarantees regarding the emissions performance. Our extensive OEM service capabilities for repair or rework ensure adherence to the original parameters.

Enhanced FE performance

Recognizing that the emissions performance of valves in operation should be verified through a leak detection and repair (LDAR) program, we offer upgrade options to further enhance Low-E performance, as required, for your most demanding applications.

Tailored solutions for methane challenges

The complete product and service offering of SLB End-to-end Emissions Solutions (SEES) is a one-stop shop for the tools and services that you need to measure, monitor, and report methane emissions.

Decarbonize your operations

Low-emission valves are part of our Transition Technologies™ portfolio and address the challenge of fugitive methane emissions. These technologies reduce environmental impact, helping you reach your sustainability goals by mitigating or preventing unintended emissions.

Learn more596

million metric tons of methane emitted into the atmosphere annually*86×

stronger global warming potential of methane vs. CO2 across 20 years*57%

CO2e emissions from oil and gas operations caused by vented and fugitive methane* Source: R B Jackson et al. 2020. Increasing anthropogenic methane emissions arise equally from agricultural and fossil fuel sources. Environ. Res. Lett.15 071002. https://iopscience.iop.org/article/10.1088/1748-9326/ab9ed2.

Industry standards and government regulations about fugitive emissions and low-emission valves

Code of Federal Regulations (CFR), Title 40, Part 61 (40 CFR Part 61): National Emission Standards for Hazardous Air Pollutants.

40 CFR Part 63: National Emission Standards for Hazardous Air Pollutants for Source Categories.

API Standard 622: Fugitive emissions testing of process valve packing in a test fixture subject to pressure, temperature, and mechanical cycles

API Standard 624: Type Testing of Rising Stem Valves Equipped with Graphite Packing for Fugitive Emissions

API Standard 641: Type Testing of Quarter-Turn Valves for Fugitive Emissions. Ball, butterfly, and plug valves with API Standard 622-compliant packing if graphite is used or various elastomer options at a range of temperatures

ISO 15848-1: Industrial Valves—Measurement, Test and Qualification Procedures for Fugitive Emissions

Specialty testing requirements for Low-E valves

With multiple international standards and differing parameters, care must be taken to ensure that qualifications meet the expectations of the operator and regulatory bodies by taking into account test media, temperature range, number of mechanical cycles, and pressure ratings.

For example, when the intended process fluid is methane, a major focus of emissions monitoring, an FE qualification test with methane is sufficient. However, when considering applications such as hydrogen, where external leakage presents a greater challenge, FE certification with helium is recommended.

The size and pressure rating of the valve must also be considered when selecting the FE testing standard. For smaller valves and lower pressure classes, API Standards 624 and 641 as well as ISO 15848-1 are all acceptable. However, for valves with a nominal bore greater than 24 in or ASME class higher than 1500, ISO 15848-1 is the only FE certification option.

These points highlight the need to fully understand the various criteria and implications when seeking to source emissions-compliant valve products.

We are leveraging our expertise to support ongoing efforts to develop a standard for FE certification of wellhead valves. Standards will evolve in time, so due diligence is required to ensure that products meet the intent of future revisions and requirements.

Special requirements for repairing Low-E valves so that they maintain their capability to prevent unwanted emissions

Qualification standards for FE-compliant valves are complex. Aside from valve size, pressure rating, and style, other aspects that affect continued compliance include seal material, design, shape, and construction; sealing stress; surface finish; and tolerance classes.

A product that does not maintain its properties would no longer be covered by its original FE certification. It is, therefore, vital that repair and redressing take account of these parameters to ensure that a refurbished or repaired product continues to be covered by its original FE compliance certification.

Count on us as your trusted OEM partner for repairs on the SLB family of FE-certified valves.

Avoid fugitive emissions with the most comprehensive Low-E valve portfolio

We have invested many years in the design, engineering, manufacturing, and testing of a comprehensive valve portfolio that meets or exceeds FE standards. We continue to take a leadership role in researching and developing industry qualification standards for these emissions.

As operators increasingly specify low-emission valves, we stand ready to manufacture and deliver valves that meet the challenging design standards for oil and gas production, processing, transmission, and storage applications. And we encourage proper OEM maintenance and repair to ensure that the valves continue performing reliably over the long term.

The content of this publication has not been approved by the United Nations and does not reflect the views of the United Nations or its officials or Member States.