Smith Bits

The number 1 name in rock-ready bits

We Know Rock

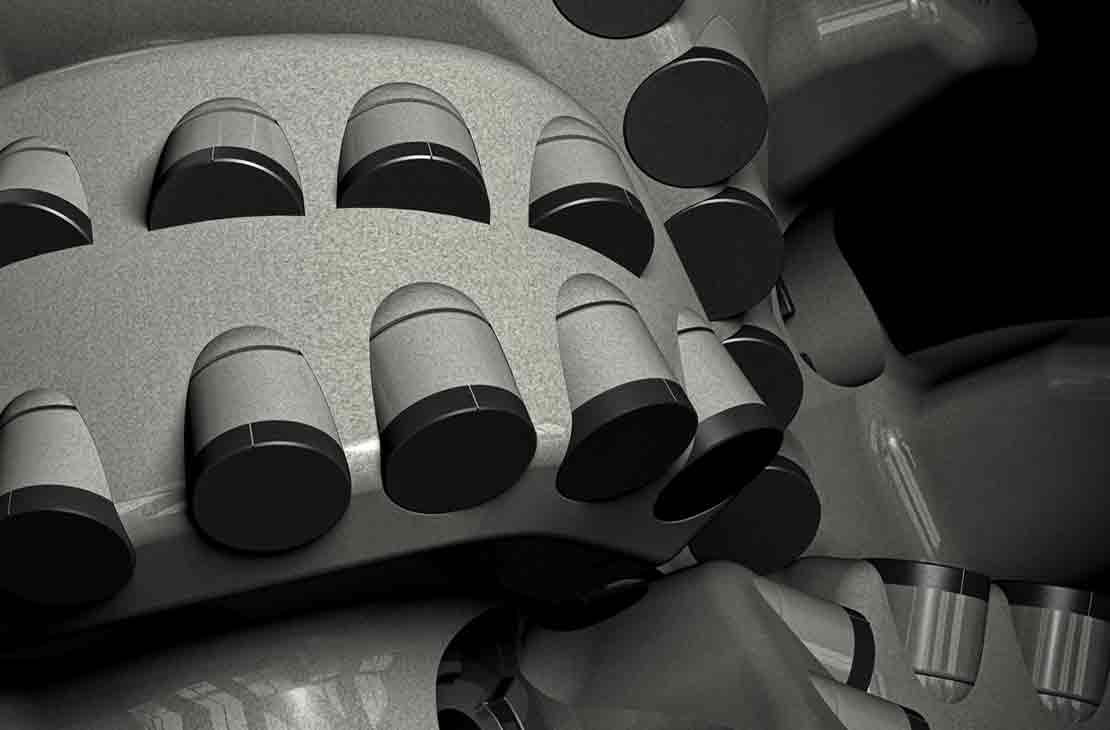

Our extensive library of field data from around the world helps identify which cutting elements and configurations perform best for any given application. Field success drives ongoing design improvements for superior, solution-specific bits that fail rock quicker and more effectively, withstand impact and wear longer, and crush ROP standards by 50% or more, driving vast industry acceptance worldwide.

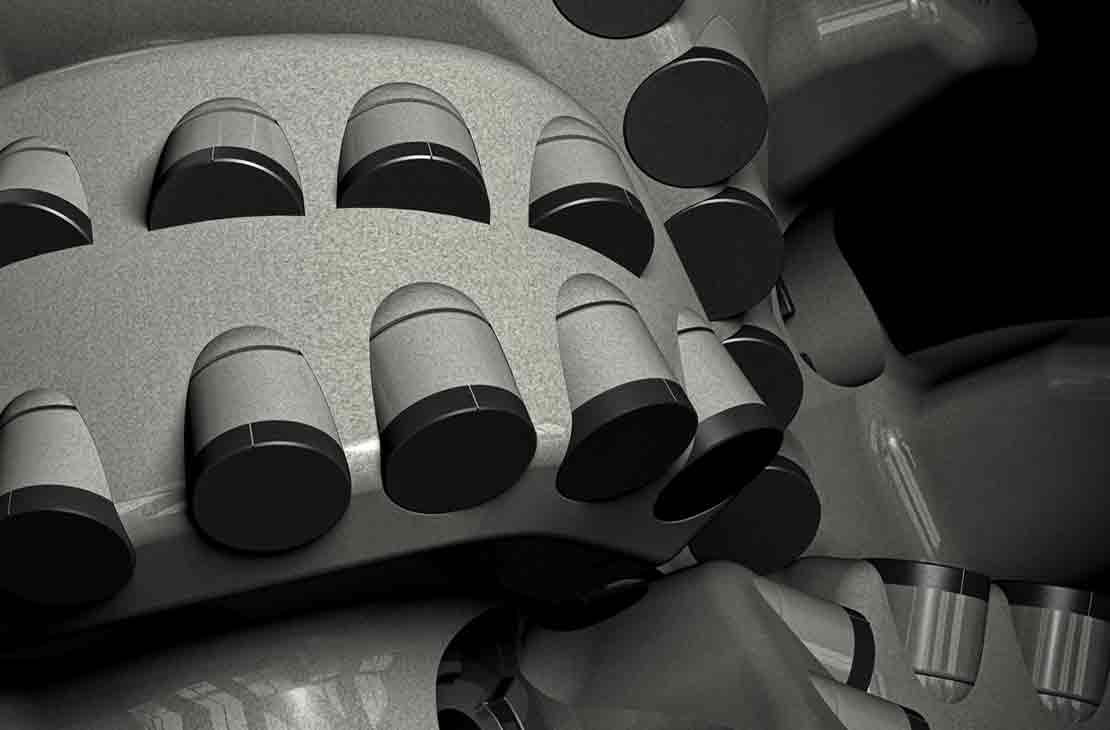

Our design process isn't about cookie-cutter solutions. We start at the rock with the kind of formation and lithology your bit will encounter. Working backward from the rock-cutter interface, analysis continues upward along the drillstring, the drive system, individual BHA components, and the total system on bit behavior in a dynamic drilling environment. The process also takes into account the specific operating parameters and the interaction between individual elements of the drilling assembly.

Not every well is exactly alike—even within the same field. That's why we persist in having such a consistent and methodical process for delivering performance and improvements that make a difference. The outcome of this process is a range of application-specific bits that consistently outperform previous designs or third-party bits when measured against the same parameters. Because when you get right down to it, you need a bit that eats rocks for breakfast.

Drill Bits

-

PDC Bits

Polycrystalline diamond compact (PDC) drill bitsHarness the workhorse of the drilling industry with bits that work harder and withstand more than PDC bits.

-

PDC Bits

Polycrystalline diamond compact (PDC) drill bitsHarness the workhorse of the drilling industry with bits that work harder and withstand more than PDC bits.

-

Roller Cone Bits

Customizable, reliable, durable TCI and milled tooth bitsAchieve superior drilling performance with durable TCI and milled tooth roller cone bits.

-

Specialty Bits

Bits to meet your performance demand needsExperience premium performance, dynamic stability, and durability.

-

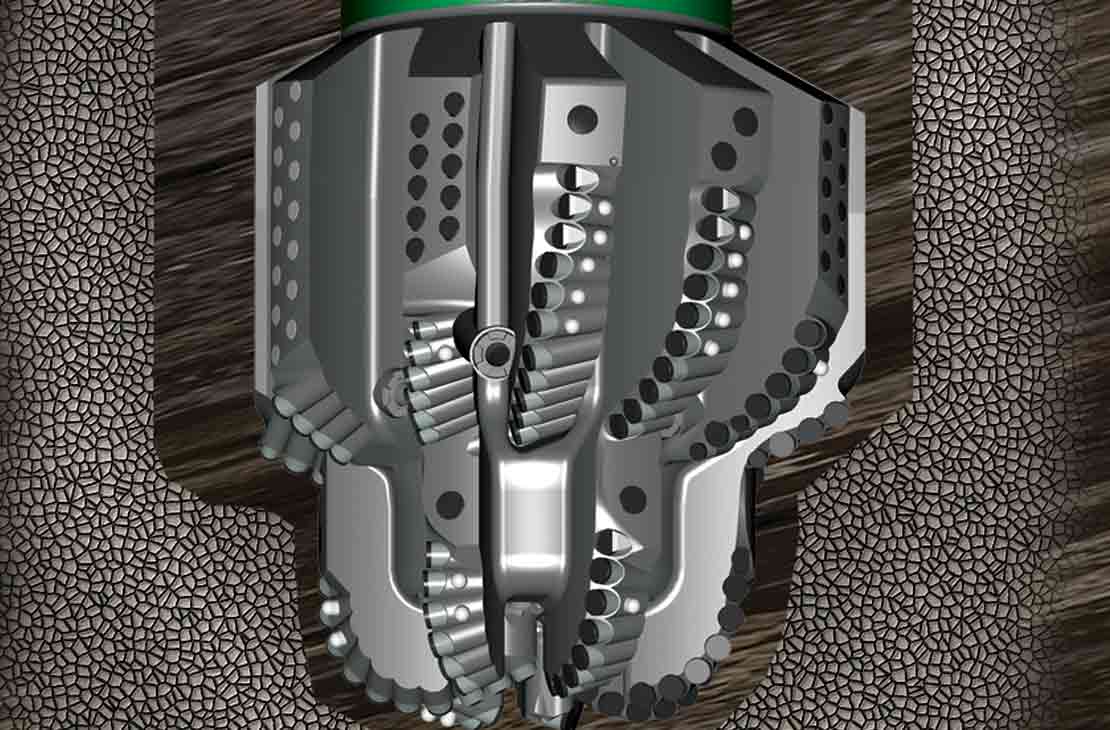

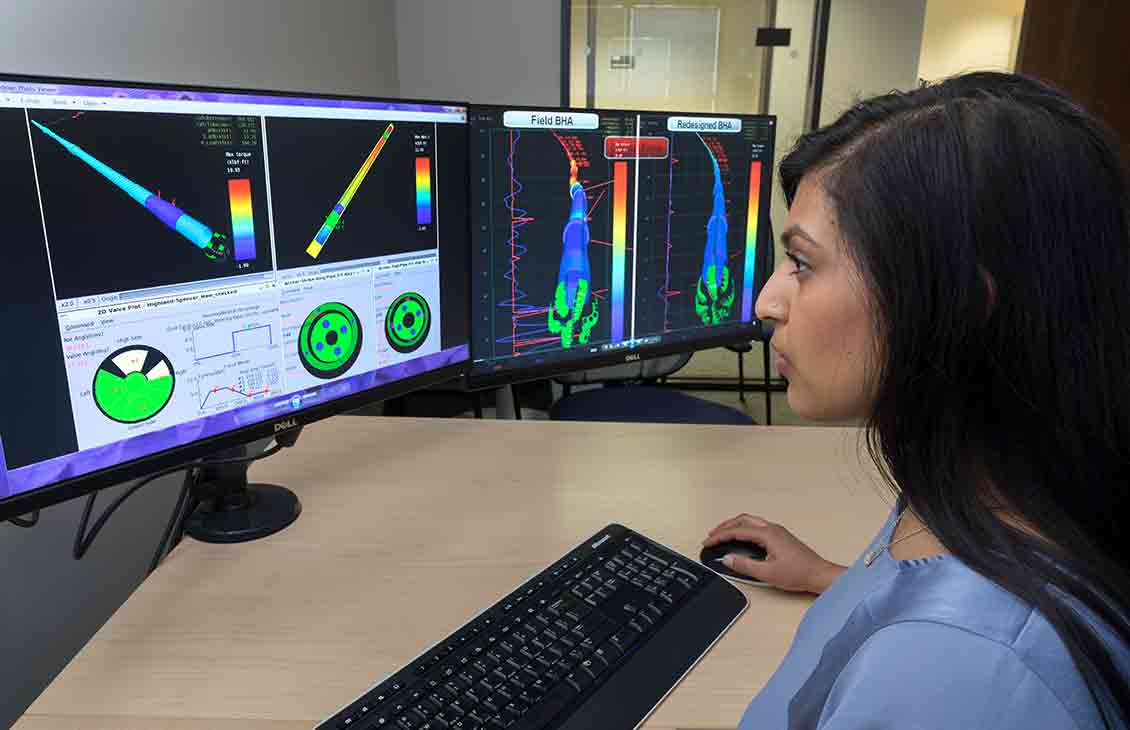

Engineered Drillstring Design

Optimized BHAs for any applicationEngineer the optimal drilling assembly for any application, including bit designs that account for each element of the BHA.

-

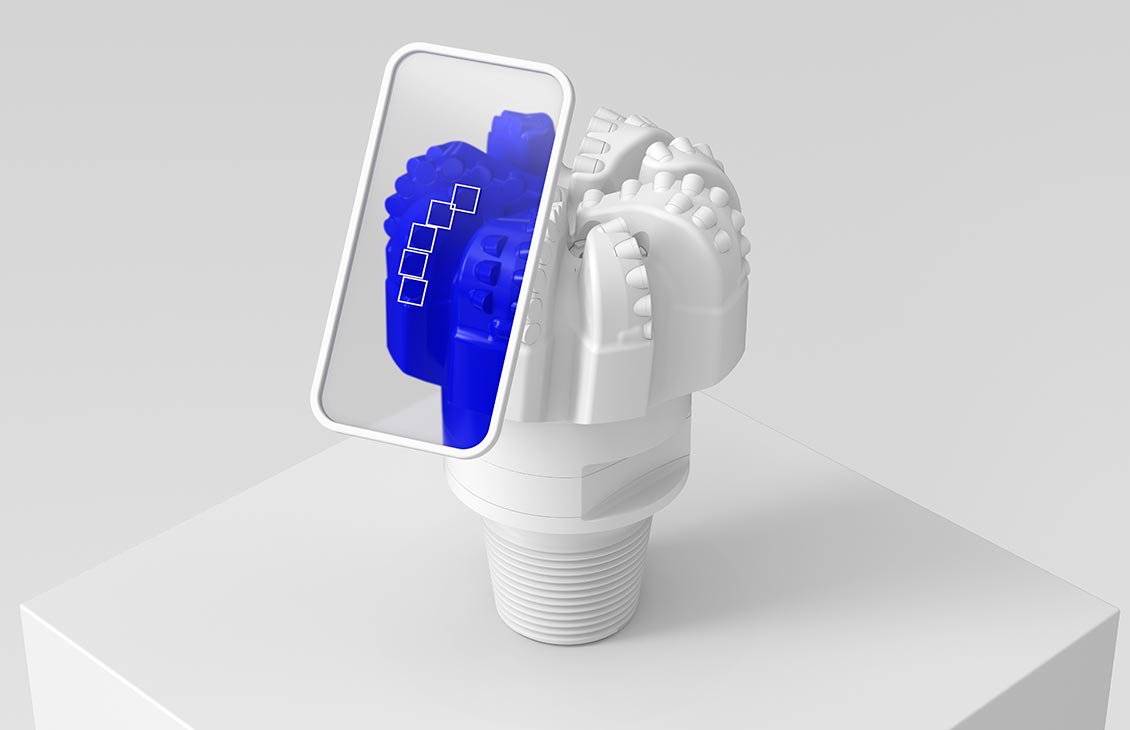

SnapScan

Rapid dull grading and drilling record systemThe SnapScan system collects accurate cutter-by-cutter dull grade information for making accurate decisions.

† Since 1999, Hart Energy E&P documents drillbit records data for different types and sizes of bits in three categories—single-run footage, cumulative footage, and ROP. Data is verified by bit run sheets from drilling contractors and operators. In a recent review, Smith Bits set 53% of the global records in the drillbit industry—more than all other bit companies combined—with 595 of the 1,123 world records.

Additionally, Smith Bits is continually recognized for advancement in bit technology, having earned the Hart Energy Special Meritorious Awards for Engineering Innovation (MEA) for cutting element technology in 2014, 2015, 2017, 2020, and the World Oil Award for drill bits in 2014.