Perforating gun systems

Comprehensive solutions optimized for the wellbore, reservoir, fluids, and completion geometry

Engineered and manufactured perforating gun systems for consistent high performance

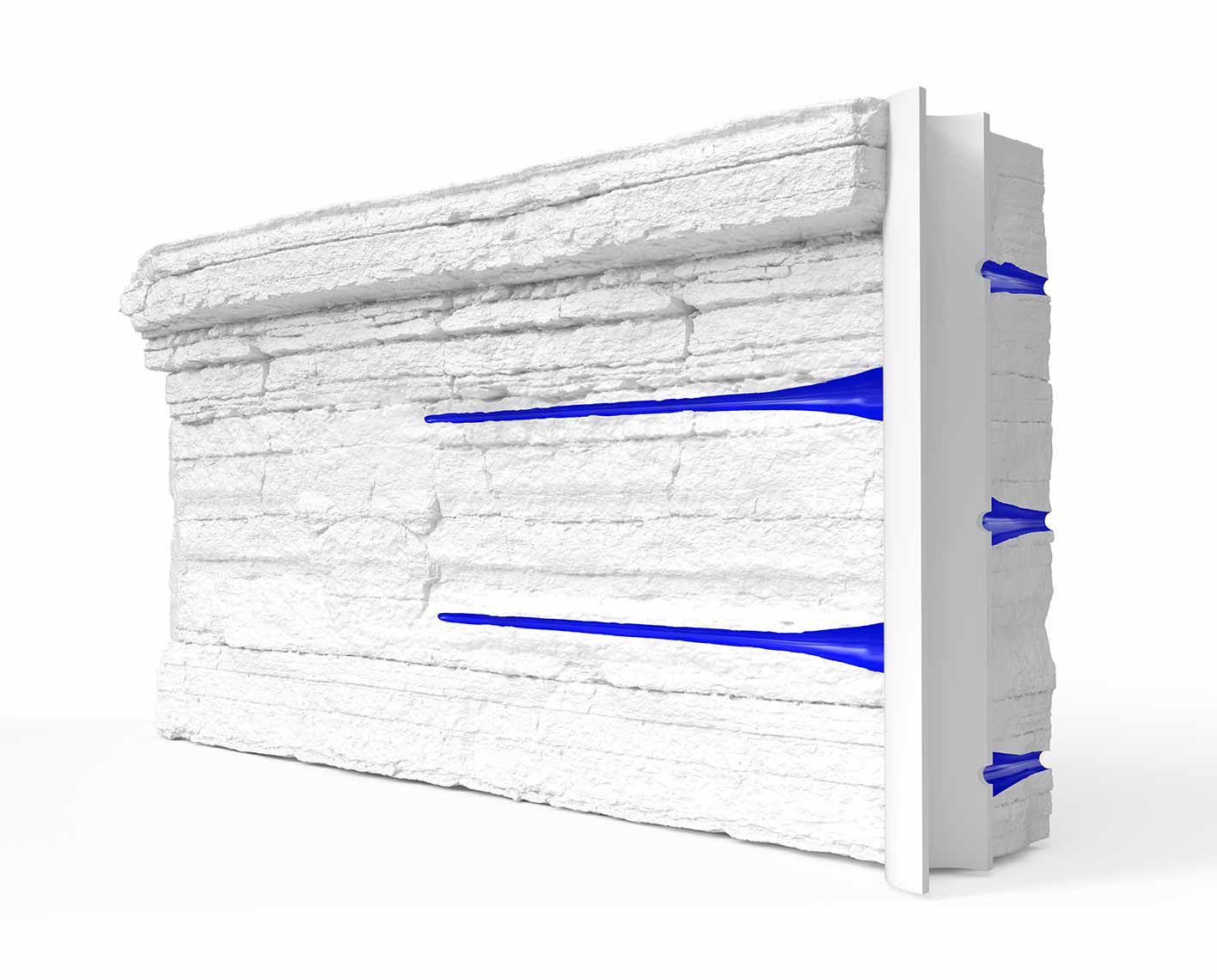

Regardless of the type of gun or perforating application, optimized gun performance begins with design and manufacturing QC, as verified by testing. Our hollow carrier and capsule perforating gun systems are engineered for the wellbore environment, reservoir, and completion geometry.

The most critical part of the gun system to manufacture with maximum quality consistency is the shaped charge, which is assembled from four components: case, main explosive pellet, primer, and liner. For routine manufacturing production runs, each charge must perform to a minimum target penetration standard related to API RP 19B Section 1.

Perforating gun systems

Hollow Carrier Perforating Gun Systems

Improve perforating performance and reduce debris with pressure-tight steel tubes that protect the charges and gun components from the well environment.

Exposed Perforating Gun Systems

Negotiate production tubing with high-performance small-diameter capsule gun systems.

Reliable perforating systems for fracture-stimulated wells

Streamline fracture stimulation of slimhole wells, sand control operations, and coalbed methane wells

Plug and abandonment

Tailor the system design to your P&A objectives with a range of entrance hole and shot density options.

Customer support

Let us help you customize the best perforating gun design to meet your challenges.