Carbon sequestration

Delivering reliable, cost-efficient, and long-term CO2 storage

Carbon storage that lasts—for good

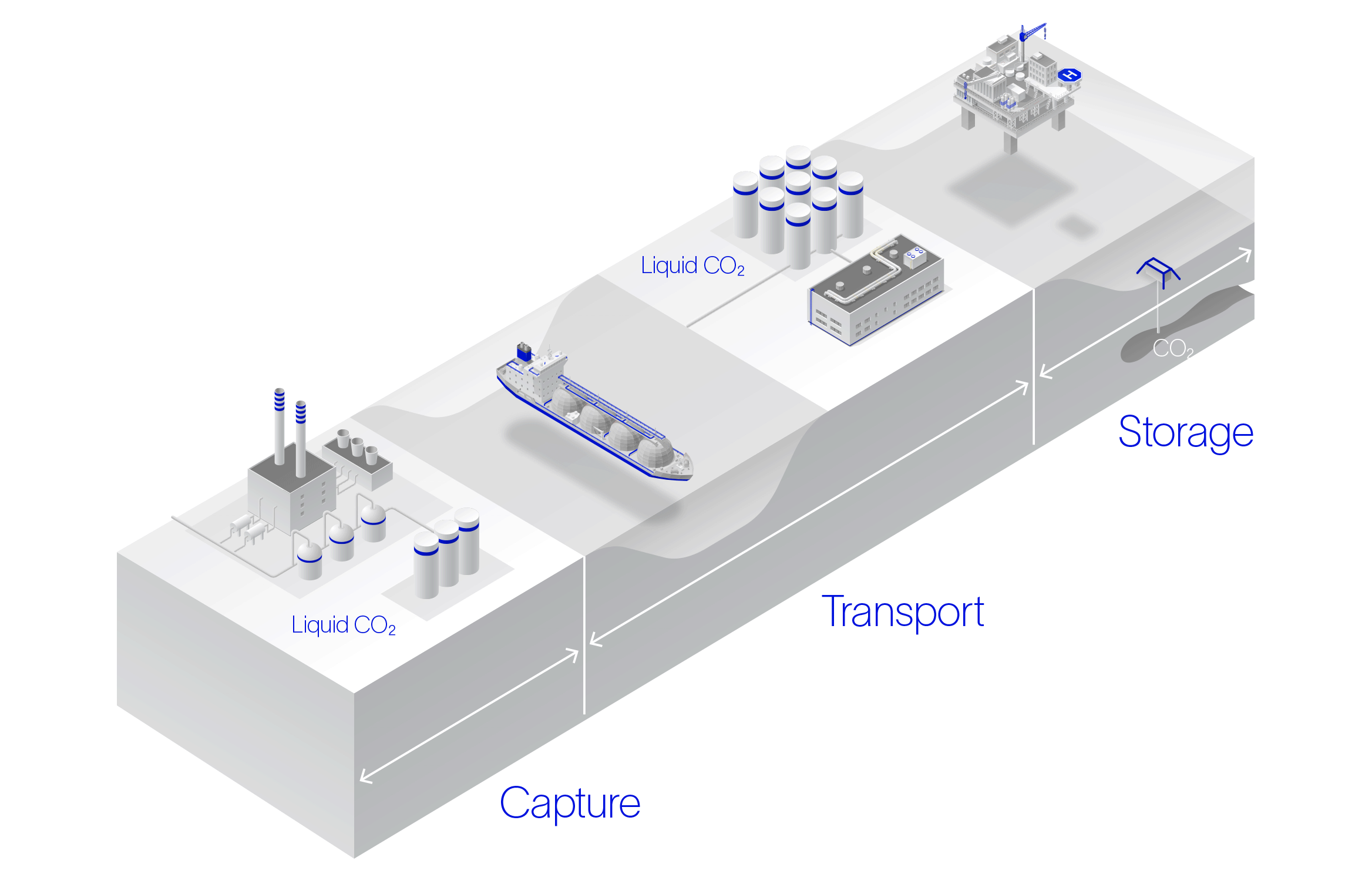

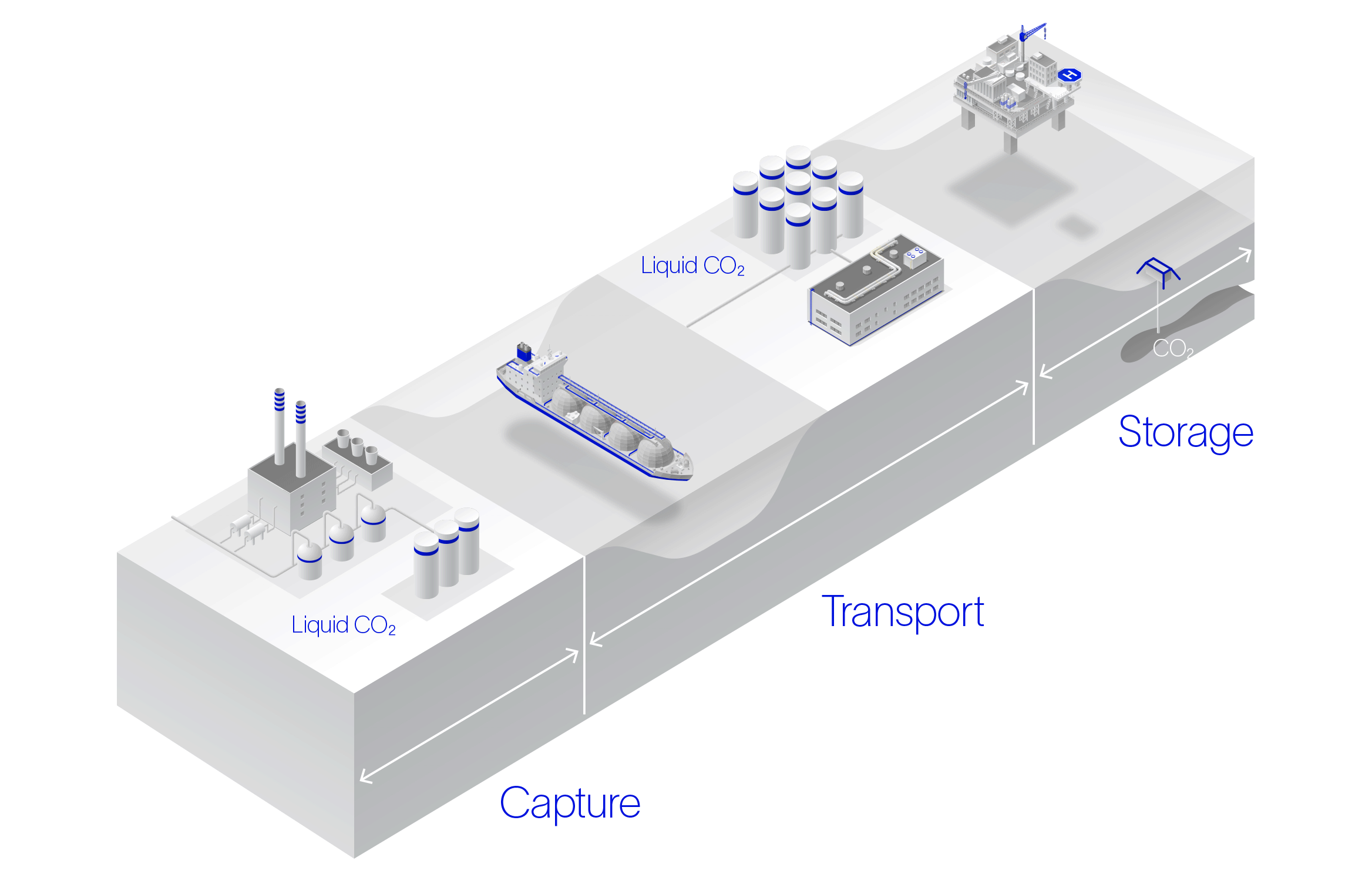

Effective carbon sequestration—or carbon storage—requires precise selection, planning, development, operation, and monitoring of the carbon storage site. Using the right experience, right know-how, and right technologies, SLB optimizes these storage phases to derisk carbon storage and lower costs.

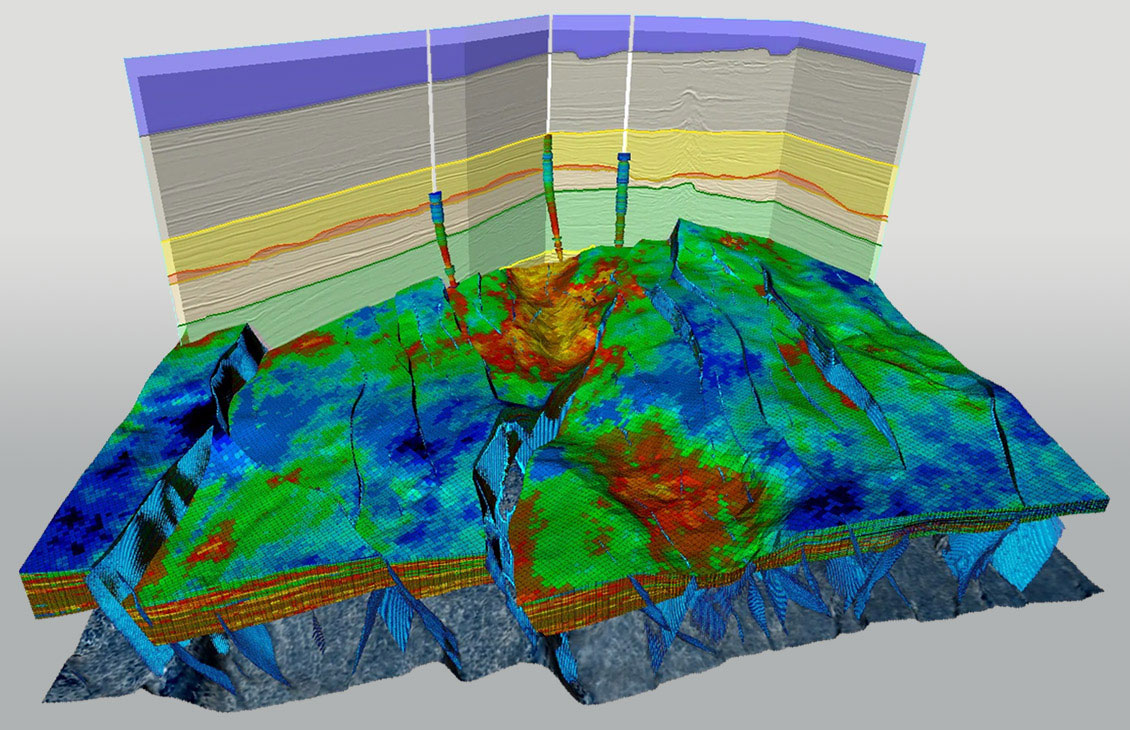

SLB has more than 100 years of experience in mapping, measuring, and modeling underground rock formations. And we’ve participated in more than 100 sequestration projects in different geological contexts over the last two decades using innovative solutions. This experience gives us detailed insight into the varied challenges posed by CO2 storage. Integrating geoscience, engineering, and digital capabilities, we’re able to deliver reliable, economical, and sustainable carbon storage projects.

Improve time to FID

We use our industry-leading suite of tools and workflows—from screening and ranking potential sites to obtaining subsurface measurements to modeling, simulating, and evaluating your site's performance. This results in a better understanding of the storage site and project feasibility and a shorter timeline to a final investment decision (FID).

Optimize planning, development, and injection

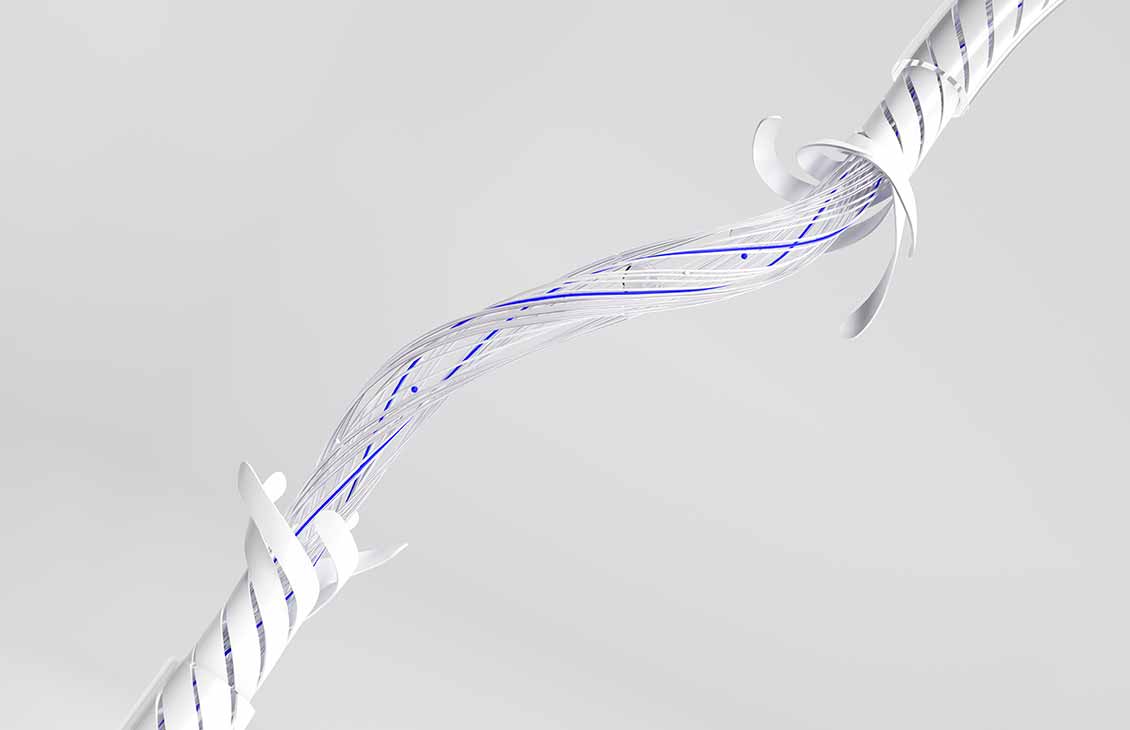

SLB solutions cover the full spectrum, from planning and site development to injection and monitoring. With a tailored suite of CCS technologies, we help to reduce risk and provide assurance for long-term storage.

Understand long-term CO2 behavior

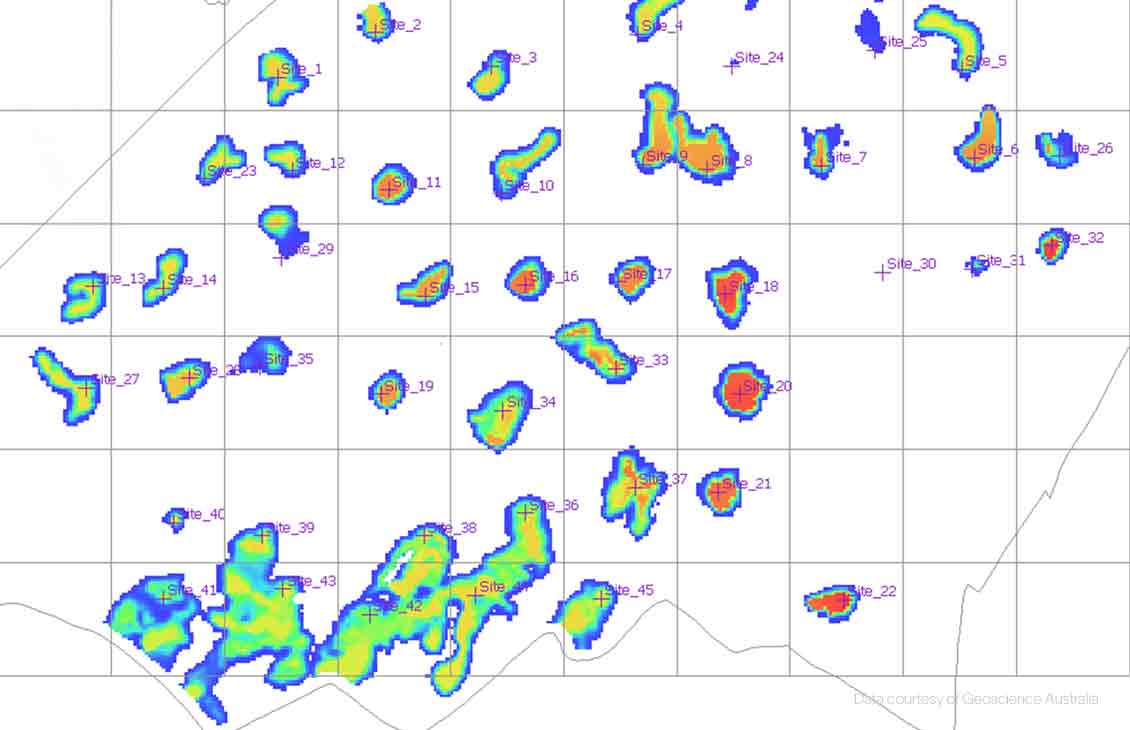

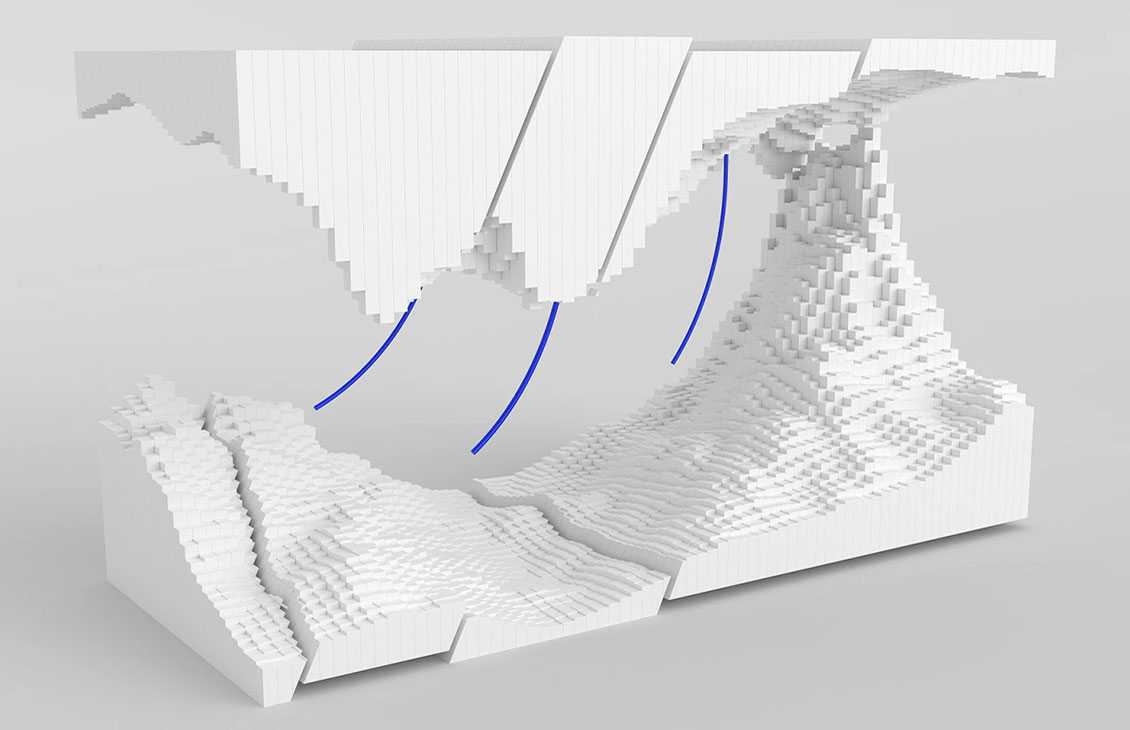

We’ve developed modeling tools to predict CO2 plume migration. Combined with our data acquisition technologies during and postinjection, this results in an accurate representation of injected CO2 volumes.

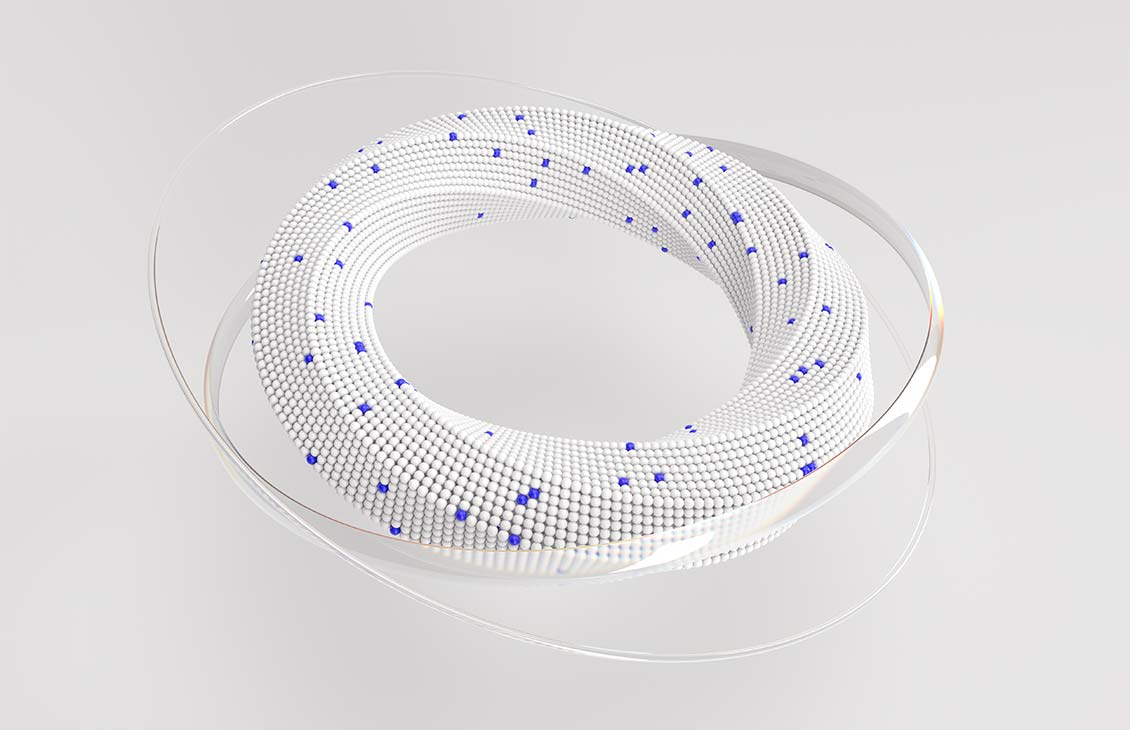

Selecting the right storage site early on is key. This will help avoid unnecessary costs associated with appraising unsuitable sites. To find the most suitable storage sites, we've developed our carbon storage site screening and ranking solution to deliver actionable insights that help derisk potential sites for economic feasibility and long-term reliability. Within your area of interest, we collect the available data and select candidates for further evaluation.

From your highest ranked prospective sites, it's essential to evaluate them for reliable, economical, and sustainable carbon storage—their feasibility. And this determines whether to proceed with storage appraisal. The key criteria:

Capacity—How much CO2 can be effectively stored at the site?

Containment—Does the storage site provide sufficient seal capacity to prevent CO2 leaks to surface?

Injectivity—What injection rates can be achieved?

We enable accurately assessing long-term performance and project viability using

- advanced measurements of capacity, injectivity, and containment using dedicated workflows

- rock and fluid labs to characterize the subsurface

- digital technologies through our carbon storage site evaluation solution

Together, we develop specific plans for reliable storage. This includes an injection plan and monitoring, measurement, and verification (MMV) plan. Whereas the injection plan defines the the optimal surface and subsurface development and carbon injection scenarios, the MMV plan demonstrates integrity of the storage site and conformance with the predicted CO2 migration models. The plan defines the technology selection that is best suited for the specific site and injection conditions and is based on evaluation of the associated risks.

High confidence in long-term integrity will only be achieved by having a site that has been well chosen, well planned, well operated, and well monitored.

That’s what we do.

Science Rob CCS video series

Join our CCS domain expert, Robert Laronga, as he uses engaging science experiments to explain various CCS topics and share insights. These insights play a crucial role in evaluating carbon storage sites for appraisal as an early, critical step in any carbon sequestration project.

Watch Video Series

Our work in action

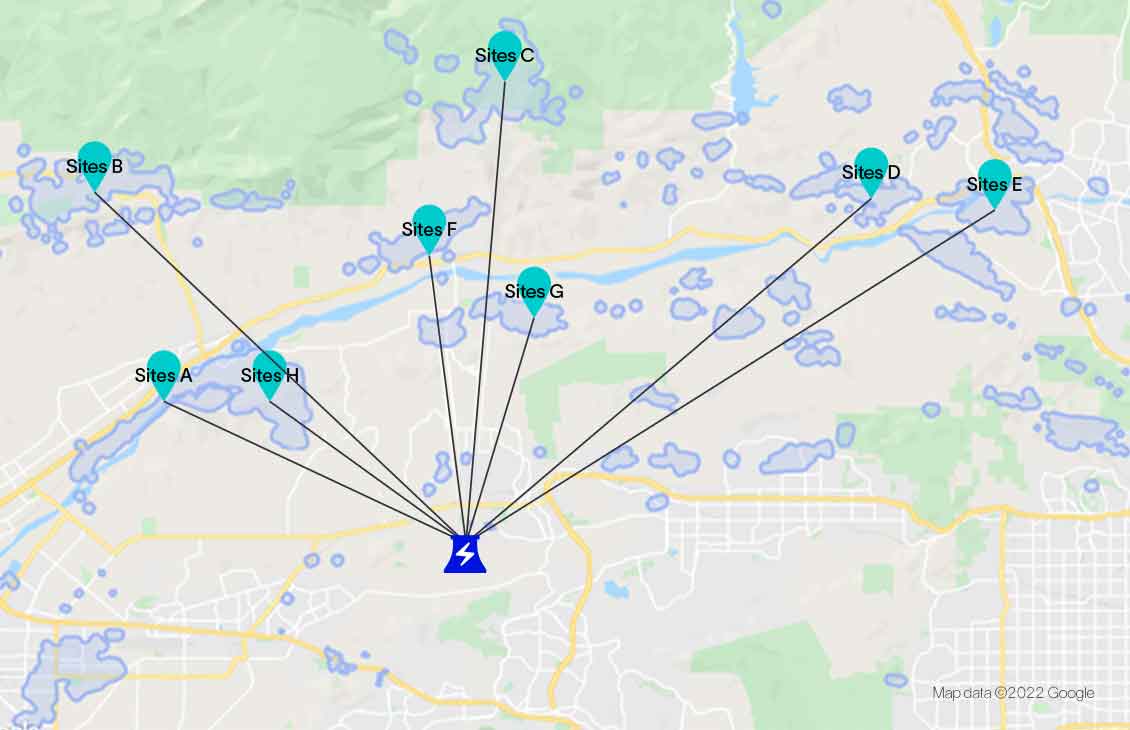

Enabled by our digital capabilities, technologies, and expertise, SLB was selected to use the DELFI cognitive E&P environment on the Norwegian CO2 project by the Northern Lights JV to streamline subsurface workflows and longer-term modeling and surveillance of CO2 storage. The JV was established to develop the world’s first open-source CO2 transport and storage infrastructure—accelerating decarbonization opportunities for European industries to store up to 5 million metric tons of CO2 per year based on market demand.

Read how we've optimized CCS

Dive deeper

-

Carbon Capture

Differentiated technologies and deep expertise to optimize your carbon capture and lower costs.

-

The Vital Role of CCUS

SLB’s bold approach to a practical and viable carbon abatement solution.

-

3 reasons why emitters struggle to get their CCUS projects right

Emission hubs can help propel CCUS projects forward, but only if the right storage and financial incentives are also involved.

-

Revolutionizing the energy landscape with integrated systems and collaborative hubs

Today’s sustainability-driven shift could benefit from integrated energy systems that harness the power of energy hubs.

-

Scaling the mountain to global CCUS and low-carbon hydrogen production

How can heavy industries and governments possibly scale CCUS activity to the levels necessary to achieve our lofty net-zero emissions ambitions?

-

Piloting the world’s first wells using 100% low-carbon power

What does sustainably powered drilling look like today and where is it heading? The answer lies in emissions-free hydrogen fuel cells.

Featured solutions, services, and products

Let's redefine what's achievable.

Featured Solution

Carbon Capture and Storage