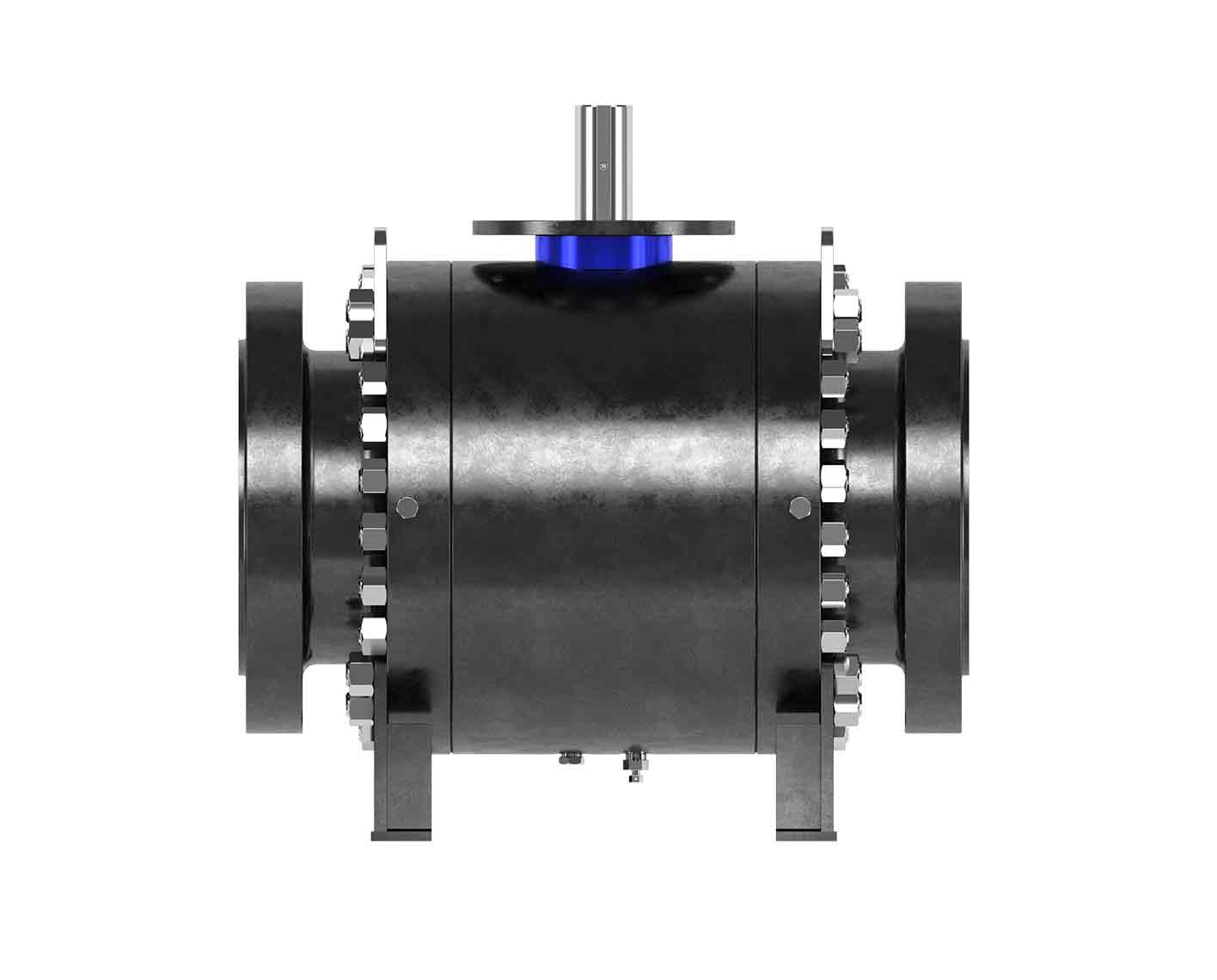

Grove B5

Trunnion-mounted, side-entry ball valve

Overview

Grove™ B5 trunnion-mounted, side-entry ball valves are constructed of forged components bolted together in a side-entry design. The standard designs are ideal for transmission and conventional production operations. They also allow for specialty configurations required in applications such as subsea installations and LNG plants.

Grove B5 ball valve.

Applications

- Onshore operations—separation, wastewater disposal, tank battery, recovery, SAGD, and oil sands applications

- Pipeline operations—transmission, emergency shutdown, pigging, and pump and compressor station applications

- Liquid tank storage—tank storage isolation, custody transfer, metering skids, and loading and unloading applications

- Offshore operations—hydrocarbon production, separation, processing and compression, and storage, metering, and exporting

- Subsea operations—fluid control and isolation for manifolds, flowlines, and riser

- Hydrogen, CCUS, renewable fuels, and ammonia service

Benefits

- Superior stem sealing performance compliant with low-emissions environmental standards

- Bolted construction that permits disassembly for field repairs

- Low maintenance and cost of ownership

- Extended service life and sealing reliability

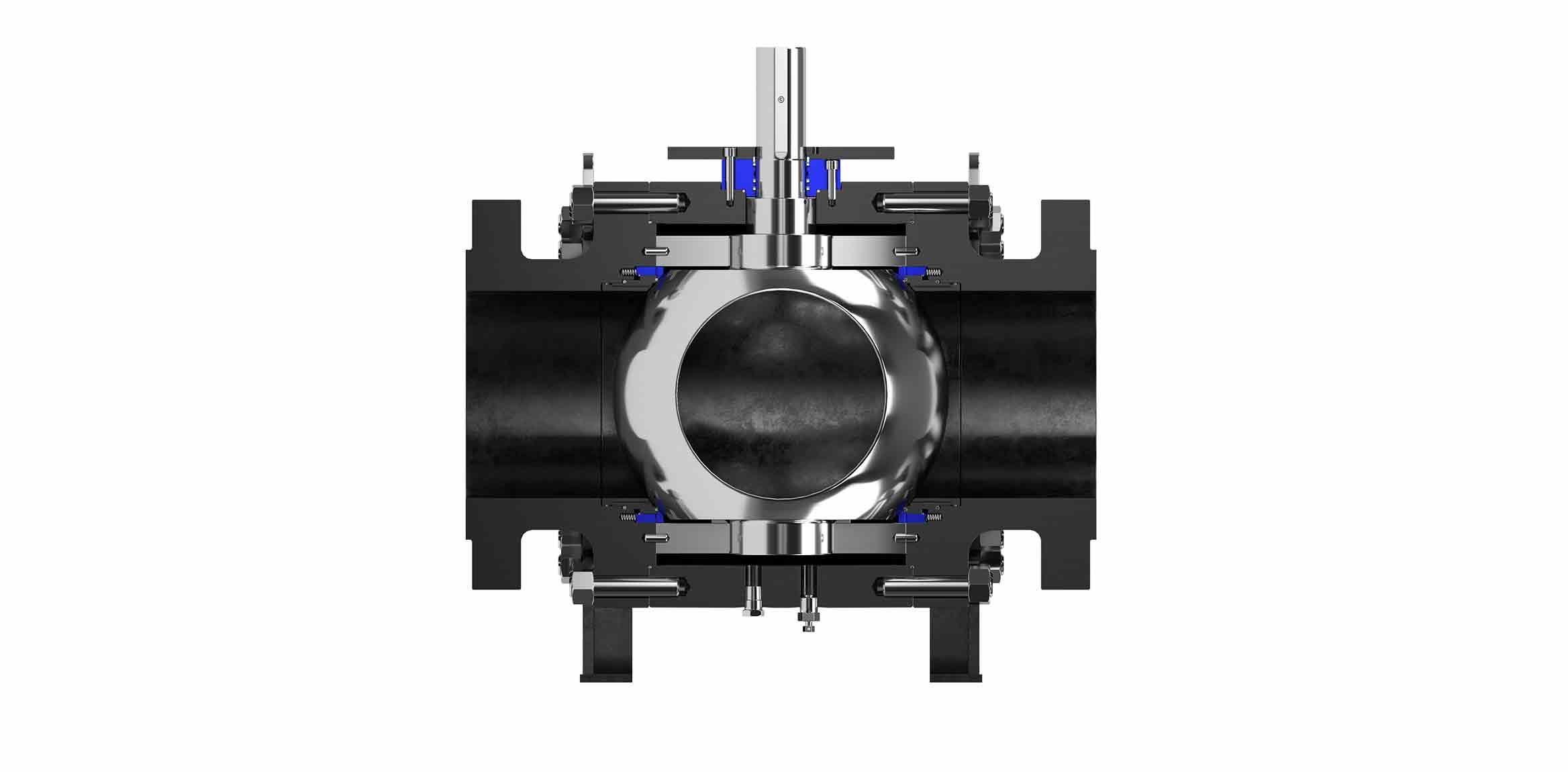

Features

- Antistatic device

- Bearing blocks that absorb the pressure load on the ball

- Body relief valve for overpressure due to thermal expansion of liquids

- Built-in sealant injection system for emergency seat seal

- Double-barrier stem seals

- Double-sealing barrier in both directions

- Integral stop in the adapter plate for a permanent reference to open and closed positions

- Large-diameter, short, coupled trunnions that reduce unit bearing loads and operating torque

- Metal-backed, self-lubricating PTFE sleeve bearing and thrust washers that reduce torque and extend service life

- Nickel plating for trim parts

- Primary metal-to-metal seal and secondary protected synthetic O-ring seal

- Stem that is separated from the ball, delivering an antiblowout design

- Trunnion-mounted ball for ease of operation at high pressure

Tech Specs