Liner Hanger Systems

Hydraulic and mechanical set liner hangers, liner top packers, and expandable systems

Xcelis™

High-performance liner hanger systems

Designed for the most challenging well environments

Liner Tieback

Metal-to-metal, gas-tight system

Solve problems with long casing strings by connecting a liner to a tieback string with full V0-qualified casing

COLOSSUS™

Liner hanger systems

Versatile options to suit various well conditions

Liner hangers and liner top packers to improve completion well construction design and operations

Well trajectory complexity, depth, pressure, temperature, and cost have increased the challenges of well construction design, planning, and operations. Long horizontal laterals in unconventional shale wells, liner drilling, extended reach wells, cemented and uncemented liners require high-performance liner hanger systems capable of: rotation to reach total depth, robust setting mechanisms tolerant of higher solids content, liner top packer sealing elements which can survive run in hole, circulating and cementing at higher rates to lift and homogenize the mud around the liner, all while controlling the equivalent circulating density (ECD) to avoid approaching the fracture gradient and damaging the formation. Once set on depth, seal integrity must be maintained through high-pressure fracturing operations in the case of some uncemented liner applications and years of pressure and thermal cycling during production.

Reduce costs and speed up well construction from deep water to land

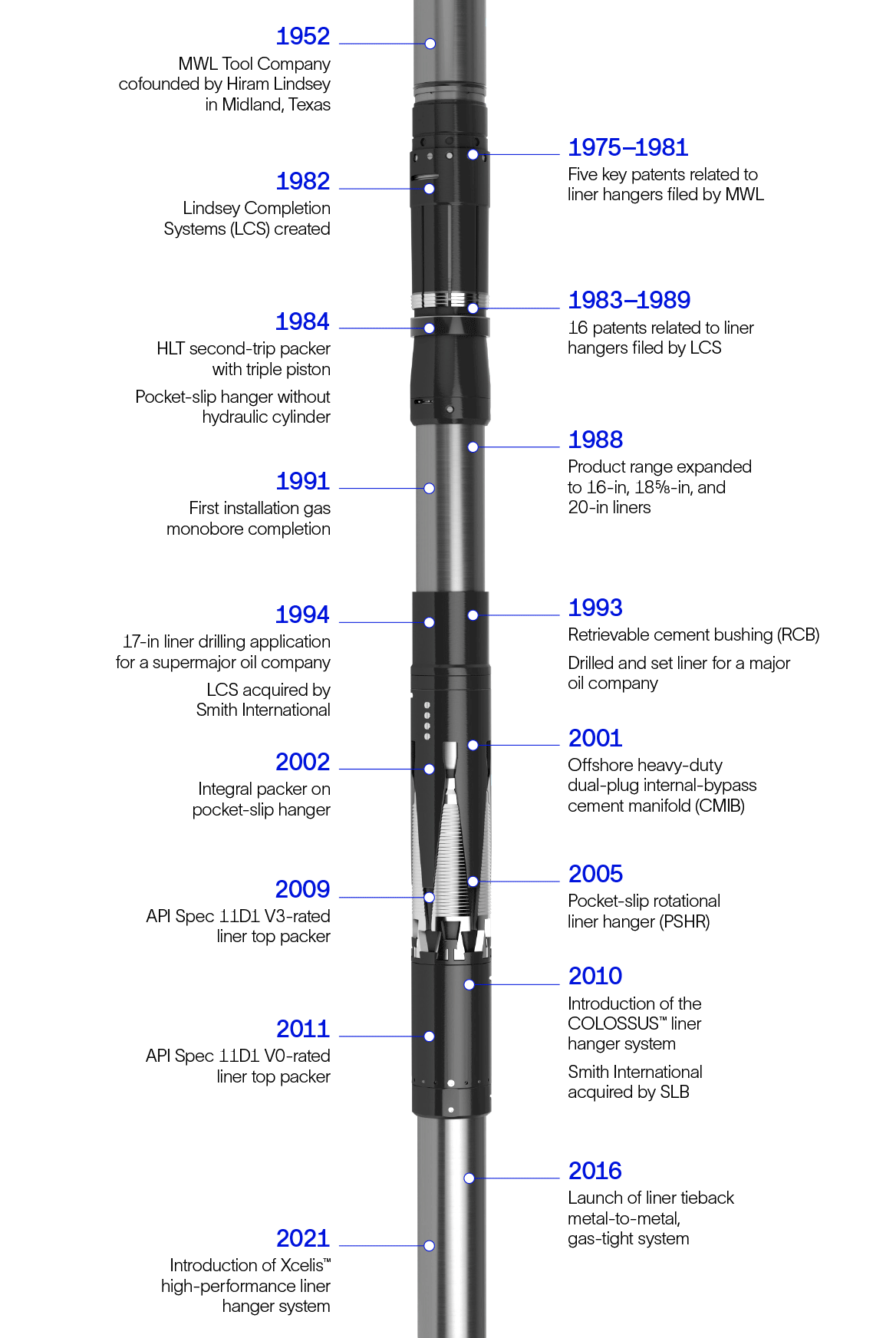

Enhance well integrity and reduce costs in well construction with a full line of liner hanger systems, equipment, and accessories for conventional and complex well applications on land or offshore. Backed by a track record of more than six decades, SLB liner hangers, liner top packers, and mechanical and hydraulic set and release running tools are engineered to suspend, support, isolate, seal, and anchor in all types of applications and environments.

With a range of available liner hanger equipment and services, Xcelis™ high-performance liner hanger systems excel in the most challenging environments, and COLOSSUS™ liner hanger systems provide versatile option to suit various well conditions.

Liner hanger system equipment

Enhance well stability and protect the casing with cemented and uncemented liner hanger systems that suit a wide range of well conditions.

Liner Hanger Systems

Liner Hangers

-

HCHR

High-capacity hydraulic rotating liner hangerDeploy heavy and long liners in drilldown applications, even in deep land, deepwater, and HPHT wells, to save time and enable rotation.

-

HPS

Configurable hydraulic pocket-slip liner hangerRun long and heavy liners with confidence, even in HPHT conditions, with or without liner rotation during running or cementing.

-

SBRD

Solid-body mechanical-set liner hangerRun light and medium-weight liners in wells where the workstring can be manipulated to set the hanger.

Liner Top Packers

Running Tools

-

CRT

Hydraulic collet running toolRun liners and release without rotation—ideal in high-inclination wells.

-

RRT

Right-hand-release running toolMechanically or hydraulically set liner hanger systems that require high torque to drill the liner.

-

RCB

Retrievable cement bushingMaintain pressure integrity for liner hanger and liner top packer operations.

-

RBS Rotational Ball Seat

Simplified running and settingSave time running and setting liner hanger systems, and reduce pressure surges.

Liner hanger expandable systems

Deploy long, heavy liners in challenging conditions—including deepwater, extended-reach, and HPHT wells—with expandable, metal-to-metal sealing for the life of the well.

-

Integrated Liner Hanger Tieback System

Incorporating the Colossus liner hanger system and a gas-tight metal-to-metal tiebackCombine all the benefits of running a liner with the sealing integrity of a full casing string.

-

Liner Tieback

Metal-to-metal, gas-tight systemConnect a liner to a tieback casing string with a permanent seal that can withstand high axial loads.

-

Load anchor

Metal-to-metal anchorEliminates load transfer onto the liner hanger and tieback system

Liner Hangers for High-Temperature Thermal Applications

Manage the most challenging thermal applications—such as geothermal or steam assisted gravity drainage—with robust liner hangers designed for wells undergoing extreme temperatures and temperature cycling.

-

LHP 650

Dual-grip thermal hydraulic-set liner hanger packerSimplify installation with rotation and improve reliability in thermal applications with nonelastomer elements.

-

RLHP 650

Retrievable dual-grip thermal hydraulic-set liner hanger packerMaximize isolation and flexibility with liner hangers in conditions that exceed temperature and pressure limits for elastomers.

-

RLTP 650

Retrievable thermal hydraulic-set liner top packerManage liner top debris, rotate into place, and keep fullbore access to the liner in thermal applications.