SELECT S

Hydrogen sulfide removal adsorbent

Mixed-metal-oxides-based adsorbents to remove harmful H2S from liquid and dry and water-saturated gas streams.

Reduce CO2e emissions by 30%–50% compared with amine sweetening and by up to 18 percentage points compared with other membrane materials

Reduce embodied carbon by up to 50% compared with alternative acid gas removal technologies

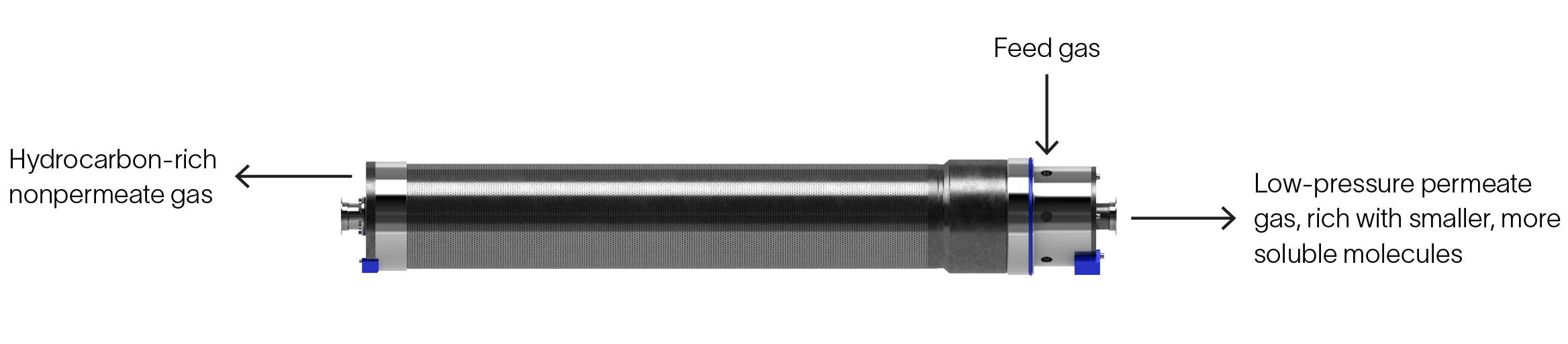

Cynara™ H2S and CO2 separation membranes consist of fibers made of a cellulose triacetate (CTA) base material, which—unlike filters—interacts with gas molecules to transport them through the membrane wall, a process called permeation. Each gas component has a specific permeation rate, determined by its ability to dissolve and diffuse through the membrane material. Highly soluble and small molecules (CO2 and H2S) permeate faster than large molecules (N2, C1, C2, and heavier hydrocarbons). The pressure difference between the higher-pressure feed gas and the low-pressure permeate provides the “driving force” for the membrane separation.

Cynara membranes are used in natural gas processing plant membrane systems with upstream dehydration (e.g., via molecular sieves). They sweeten high-pressure feed gas via bulk separation of H2S and CO2 and recover natural gas liquids (NGLs). The CO2 can be used for enhanced oil recovery (EOR) operations or carbon capture and sequestration (CCS). Cynara membranes can withstand NGL-rich conditions, varying feed gas mixtures, H2S, or a combination of these conditions, which are unsuitable for some other polymeric membranes.

Cynara membrane elements can be oriented vertically or horizontally. Vertically oriented elements are available in diameters up to 30 in, enabling significant acid gas treatment capacity. They can be part of the initial design of a natural gas treatment plant. They can also be used to debottleneck an existing amine-based acid gas removal system—or reduce the size of a new one—by introducing a hybrid natural gas sweetening process.

Horizontally oriented Cynara membrane elements are designed to fit in 8-in and 8 1/4-in tubes built to ASME B31.3 specifications. Intended for retrofitting existing membrane installations to improve separation performance, they have been operationalized in packaging that enables simple plug-and-play replacement of flat-sheet cellulose acetate, hollow-fiber polyimide, and other polymeric membrane elements without infrastructure modifications. They have delivered consistent improvement in production capacity and hydrocarbon retention versus other CO2 removal membranes during competitive trials and full membrane replacement in existing systems. Read a case study from Australia.

The asymmetric hollow-fiber membranes enable natural gas treatment facility operators to benefit in multiple ways.

Large-diameter, vertically oriented Cynara membrane elements enable a greatly reduced footprint, which is especially beneficial offshore, where space is at a premium. As a result, embodied carbon decreases by up to 50% compared with alternative acid gas removal technologies.

Using Cynara membranes to replace amine-based acid gas removal units or reduce their size decreases the energy necessary to heat and circulate amine solvents. When combining membranes for bulk removal of acid gases with amine-based acid gas removal for the final polishing stage, a 30%–50% reduction in emissions can be achieved.

Lastly, the higher hydrocarbon retention provided by Cynara membranes versus alternative membrane materials enables pursuit of CCS for the high-purity CO2 outlet stream (instead of thermal oxidation of the permeate gas), further reducing emissions intensity.

Learn about our collaborative approach and full field development solutions that drive high performance while reducing environmental impact throughout the life of your asset.

Thousands of individual asymmetric, hollow Cynara membrane fibers are packaged within each cylindrical membrane element. Pressurized feed gas flows along the fiber bundle; the more soluble acid gas components (CO2 and H2S) preferentially permeate to the bore side of each fiber, where they are combined. This low-pressure permeate flows out at the end of the fiber and is collected for CCS, CO2 EOR, or additional processing. The hydrocarbon-rich nonpermeate gas continues through the plant for further processing and sale or direct use.

Using multiple stages and optimized arrangements enables the bulk acid gas removal unit to efficiently handle a wide range of feed gas compositions, flow rates, and operating parameters, such as pressure and temperature. Operation is fully automatic, and the modular system enables operators to add capacity incrementally as well as provide a large turndown capacity.

The following SLB products are protected by patents in the U.S. and elsewhere. This website is provided to satisfy the virtual patent marking provisions of various jurisdictions including the virtual patent marking provisions of the America Invents Act and to provide notice under 35 U.S.C. §287. The following list of SLB products may not be all inclusive, and other SLB products not listed here may be protected by one or more patents.

Cynara: Protected by U.S. Patents US 10,427,094; US 9,186,629; US 11,745,138; US 11,992,803; US 11,918,956, US 9,630,141. Additional patents may be pending in the U.S. and elsewhere.

Since the first installation in 1983, Cynara membranes have established an impressive track record of reliability, operating with minimal downtime and average availabilities up to 99% since startup. We design and provide custom membrane pretreatment equipment, membrane systems, and field operation and support services for energy companies’ operating facilities worldwide, both onshore and offshore. Solutions can address turnkey projects, gas dehydration, liquid hydrocarbons recovery, and acid gas separation. High-capacity projects exceeding 1,200 MMcf/d, with inlet CO2 concentrations from 5% to 85% and outlet concentrations from 50% to 1.5%, can also be engineered. Our ongoing experience enables recommending the most economical and reliable long-term solution, whether it is a stand-alone membrane system or a hybrid system with other gas processing technologies.

By centralizing related services, such as membrane manufacturing, R&D, testing, quality control, and engineering, we achieve quality, product availability, economies of scale, and a level of product responsibility that are impossible with an outside supplier or multiple suppliers. You benefit from full control of scheduling, continuous quality upgrades, performance enhancements, rapid implementation of new designs, state-of-the-art-manufacturing facilities, field-proven expertise, and digital services to assure performance.

Read SPE-211191 to learn about our advancements in CO2 separation membrane technologies and how they have benefited operators.

The content of this publication has not been approved by the United Nations and does not reflect the views of the United Nations or its officials or Member States.