Industry Article Future Offshore Well Construction to be Defined by Collaboration, Remote Solutions

How advanced remote operations and autonomous systems are shaping the future of well construction.

Seamlessly bridge the gap between drilling and completions

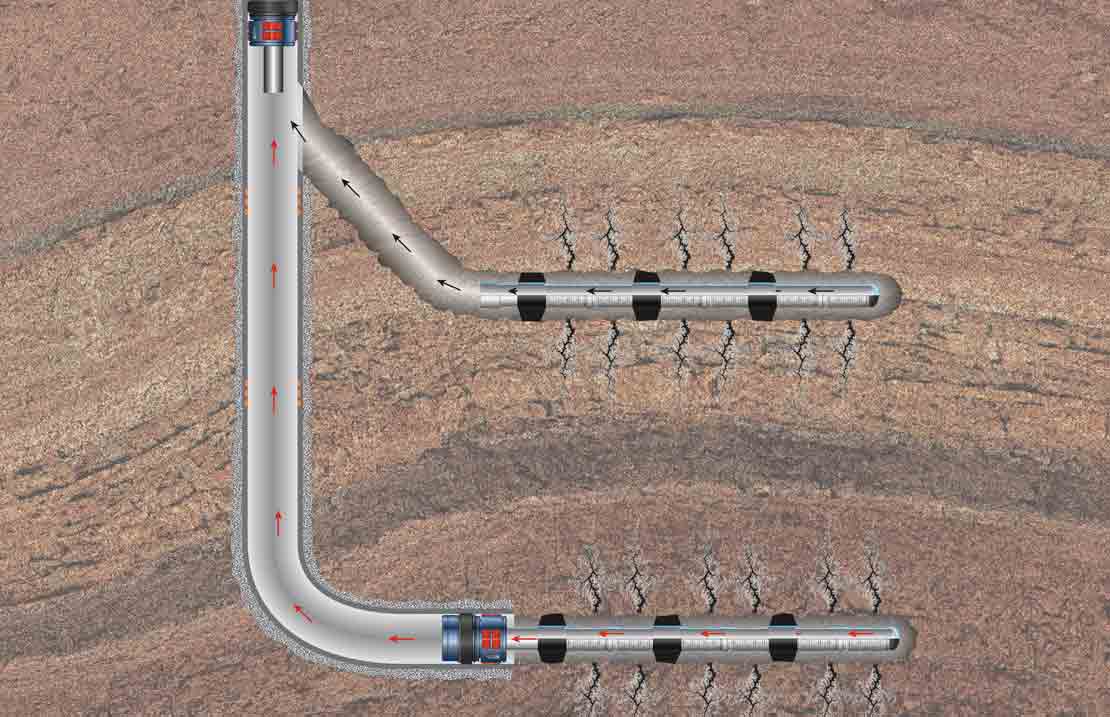

Well construction brings workflows together to seamlessly bridge the gap between drilling and completions. We put the right information in the right hands at the right time so we can deliver a smart drilling program that maximizes accuracy, efficiency, and value—while also minimizing risks.

We develop a digital plan for intelligent drilling execution that enables efficient handoff to a digitally informed completion team for optimal hardware and fluids delivery to prepare the wellbore and the reservoir for production. The integrated preparation and analysis mean that, when challenges arise, contingencies are in place to maintain project progress and continuously improve the process from well to well.

Well construction means integrating activities, processes, people, and technology; monitoring deviations; and providing solutions that allow for dynamic changes to the plan and improving learning for the next time.

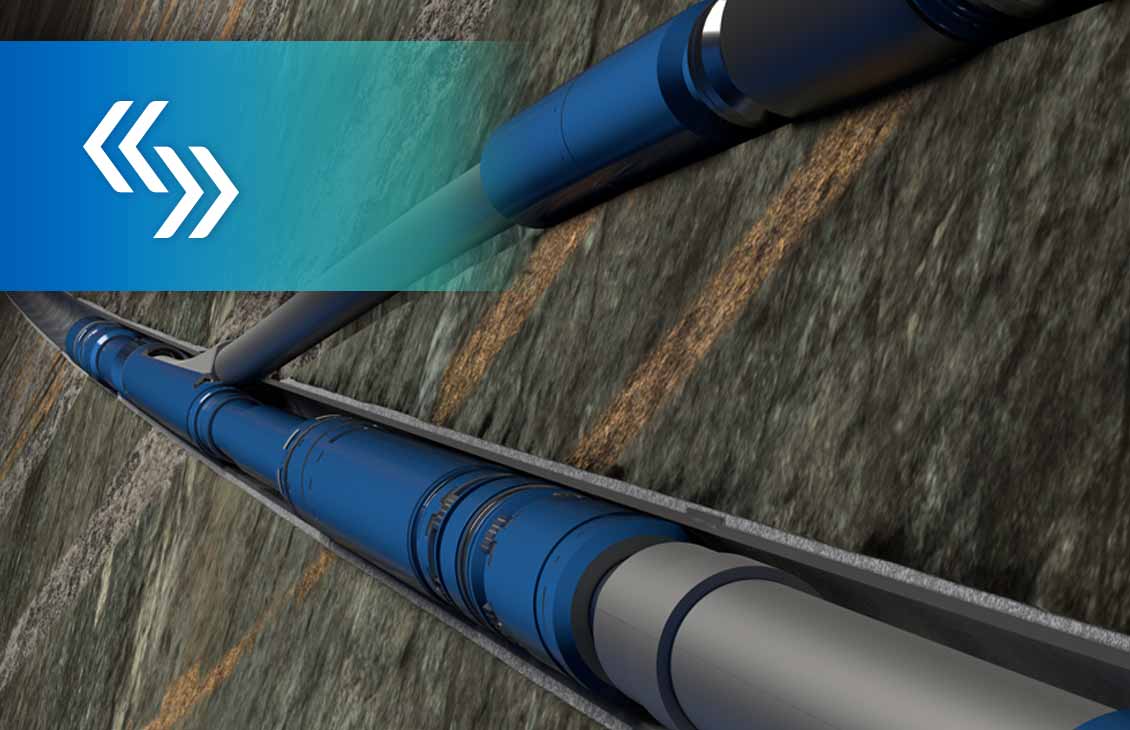

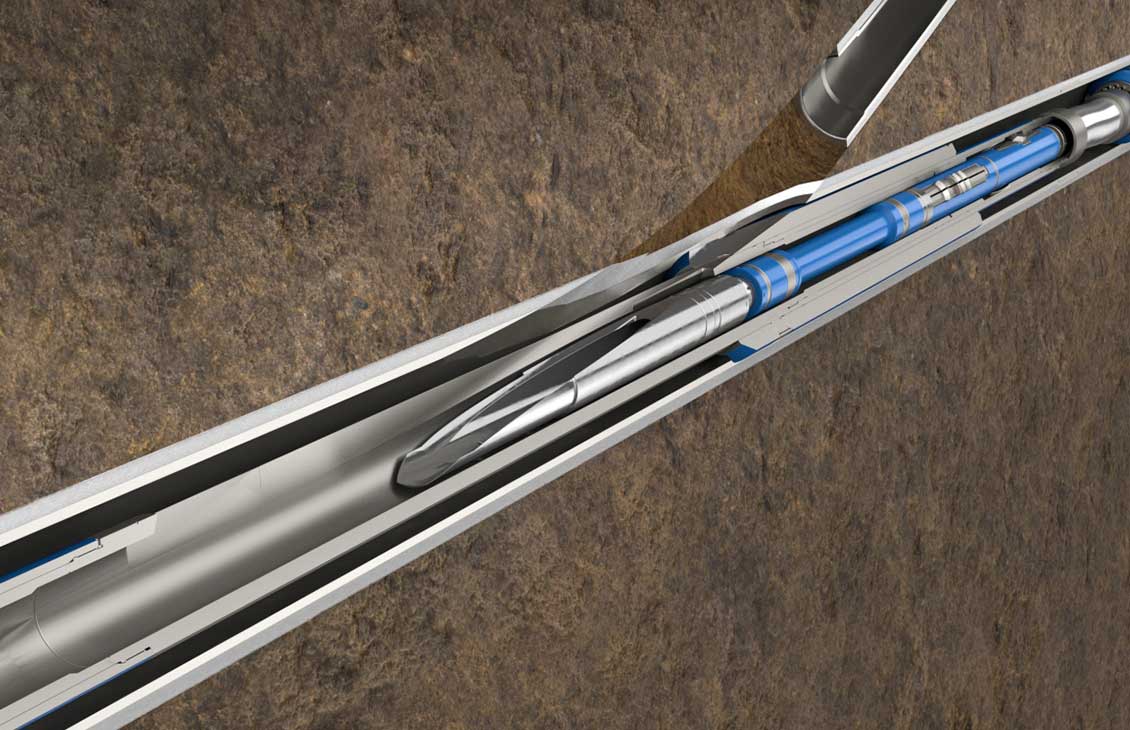

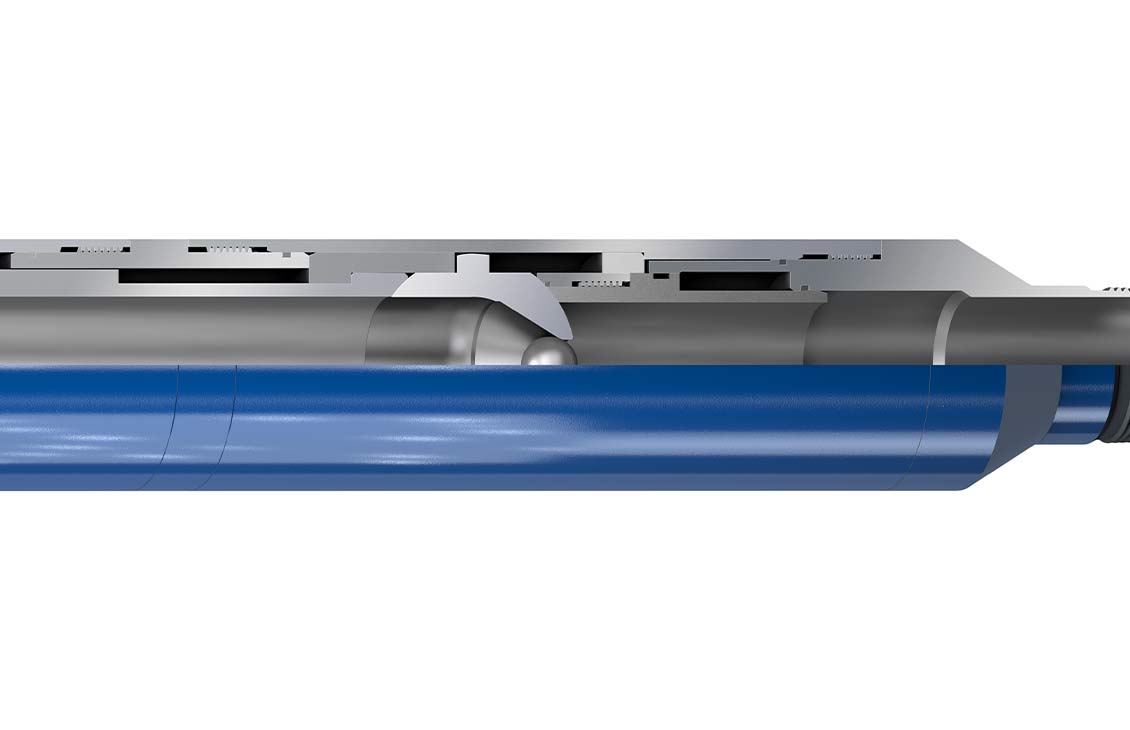

Confidently reenter existing wells to add laterals that increase reserves while minimizing investment.

Prepare selective access and multiple kickoff points for current and future sidetracks and multilateral wellbores. View

Save time on your completion by enabling fracturing in both the lateral bore and main bore in a single trip. View

Reduce costs with multilateral technology that is compatible with conventional completion options. View

Isolate up to 2,500 psi [17.2 MPa] at the junction, and combine simple installation with flexibility. View

Maximize performance with a reliable, modular large-bore junction. View

Enable rigless through-tubing intervention (access or isolation) in multilateral wells. View

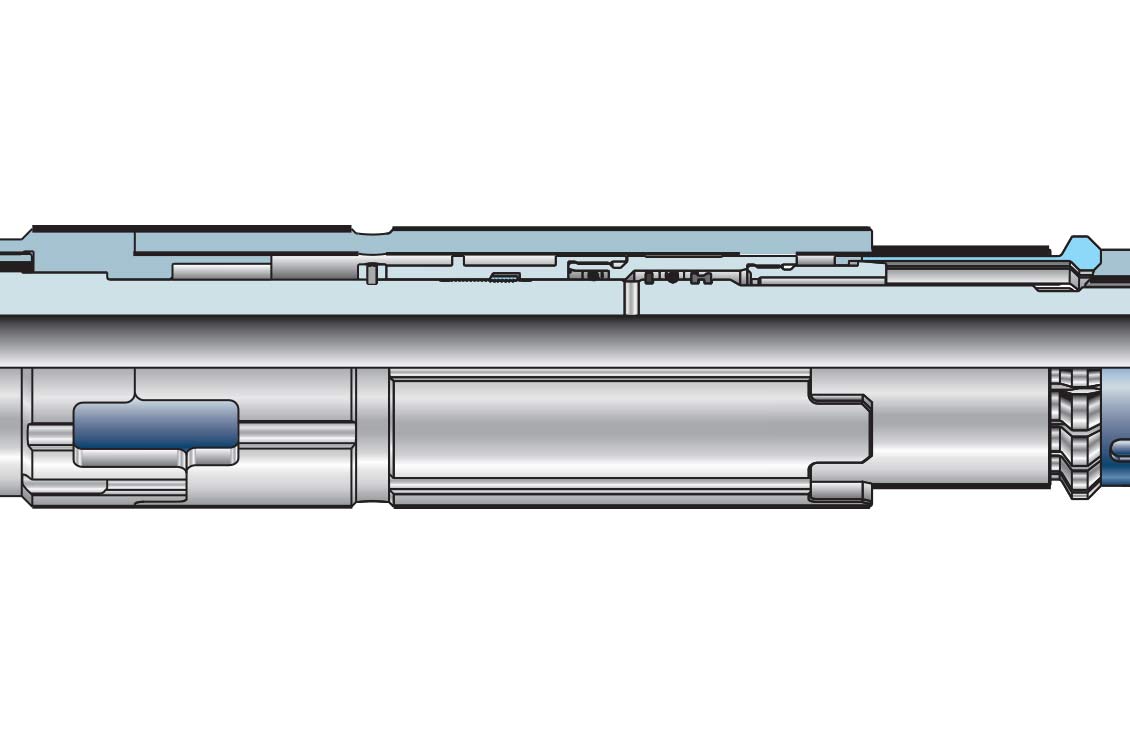

Enhance well stability and protect the casing with cemented and uncemented liner hanger systems that suit a wide range of well conditions.

Run liners and release without rotation—ideal in high-inclination wells. View

Mechanically or hydraulically set liner hanger systems that require high torque to drill the liner. View

Maintain pressure integrity for liner hanger and liner top packer operations. View

Save time running and setting liner hanger systems, and reduce pressure surges. View

Facilitate liner deployment with push, pull, and rotation capabilities ideal for high-temperature and thermal wells. View

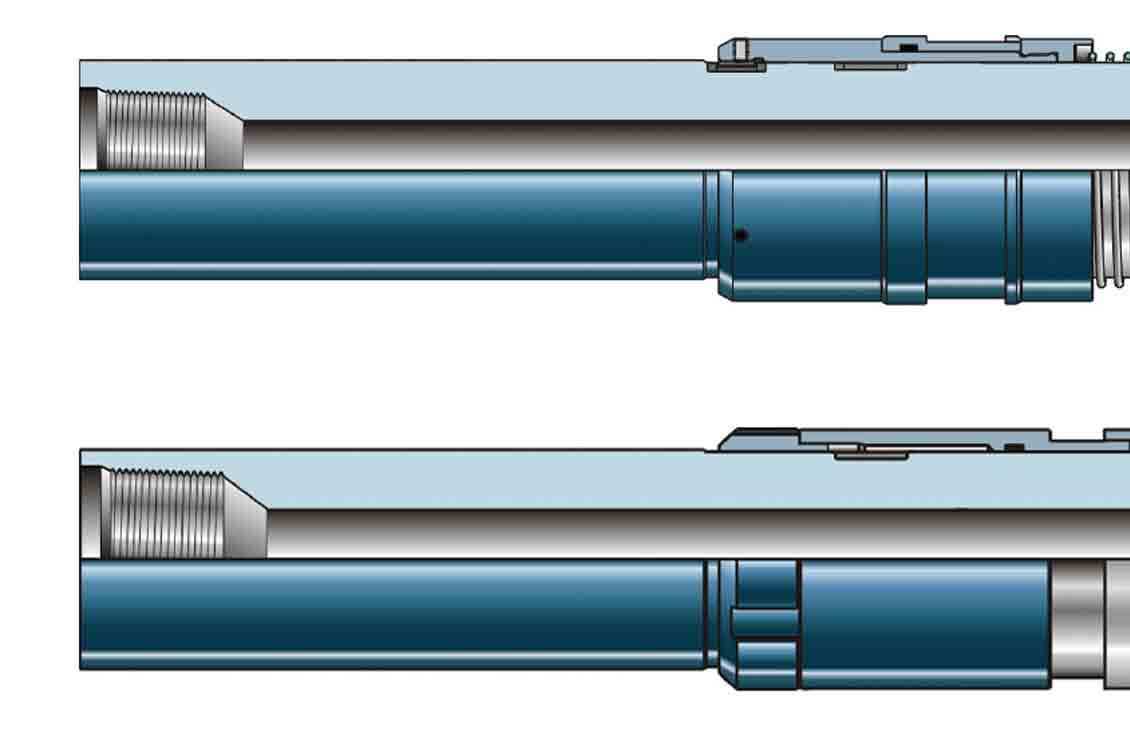

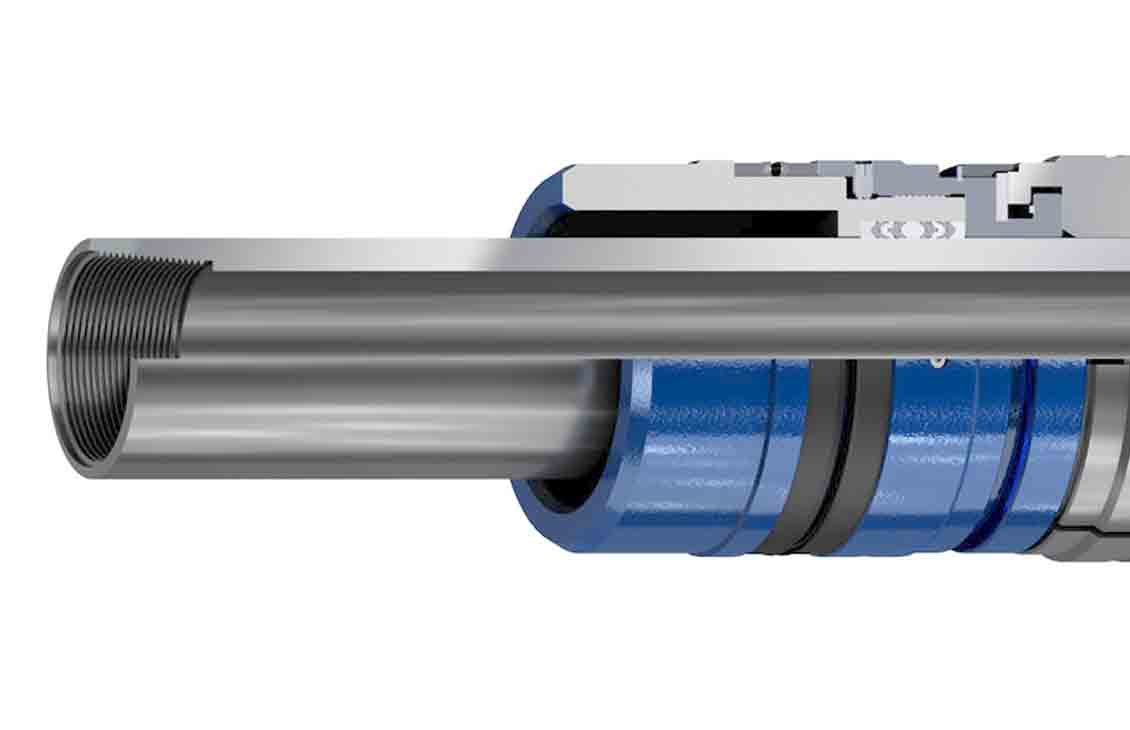

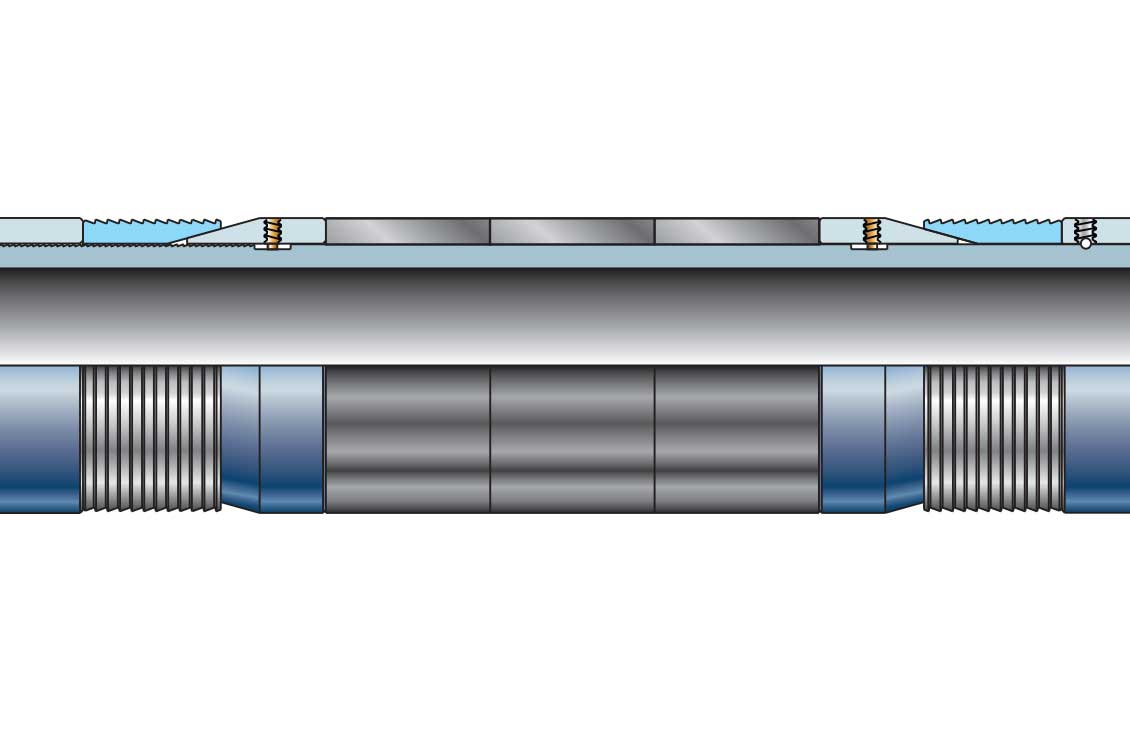

Deploy long, heavy liners in challenging conditions—including deepwater, extended-reach, and HPHT wells—with expandable, metal-to-metal sealing for the life of the well.

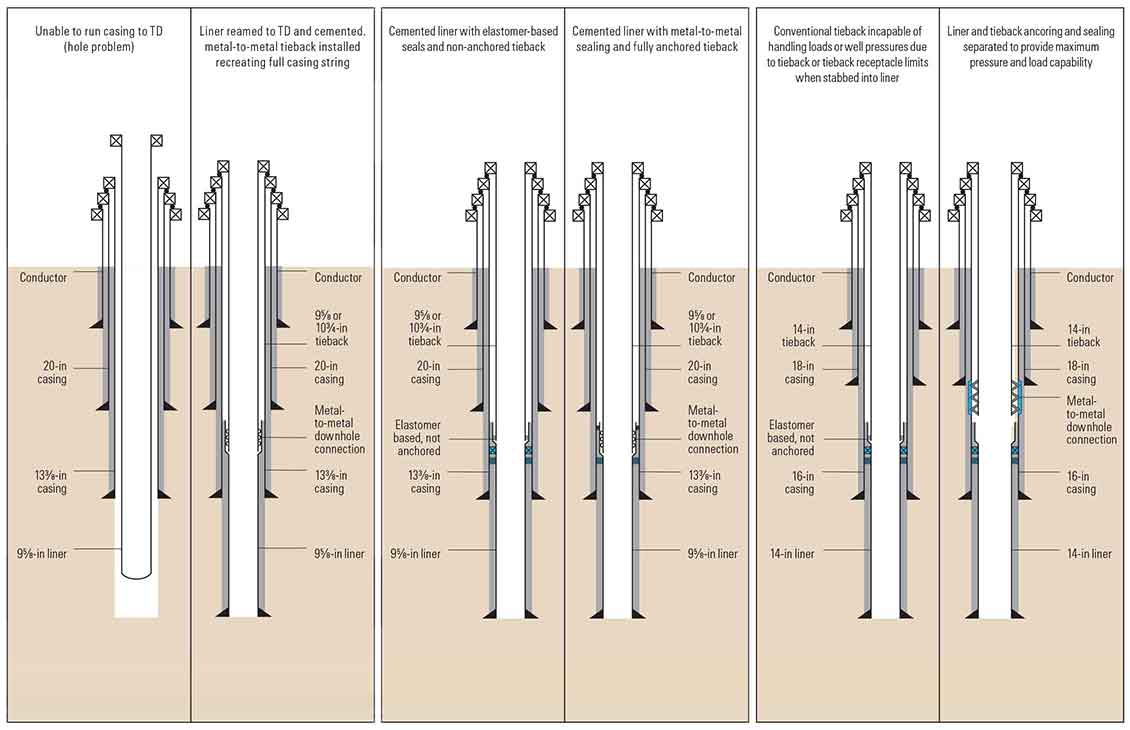

Solve problems with long casing strings by connecting a liner to a tieback string with full V0-qualified casing integrity. View

Solve problems with long casing strings by connecting a liner to a tieback string with full V0-qualified casing integrity. View

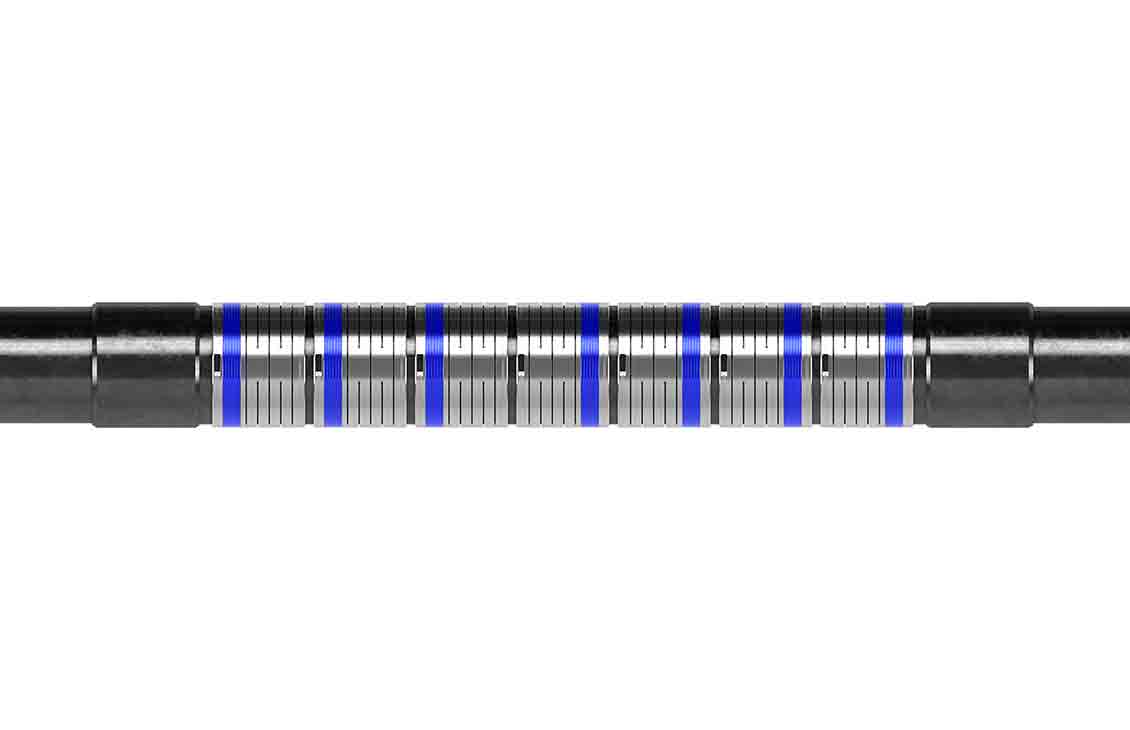

Use conventional liner hanger systems with heavier axial loads by deploying an anchor that manages the loads. View

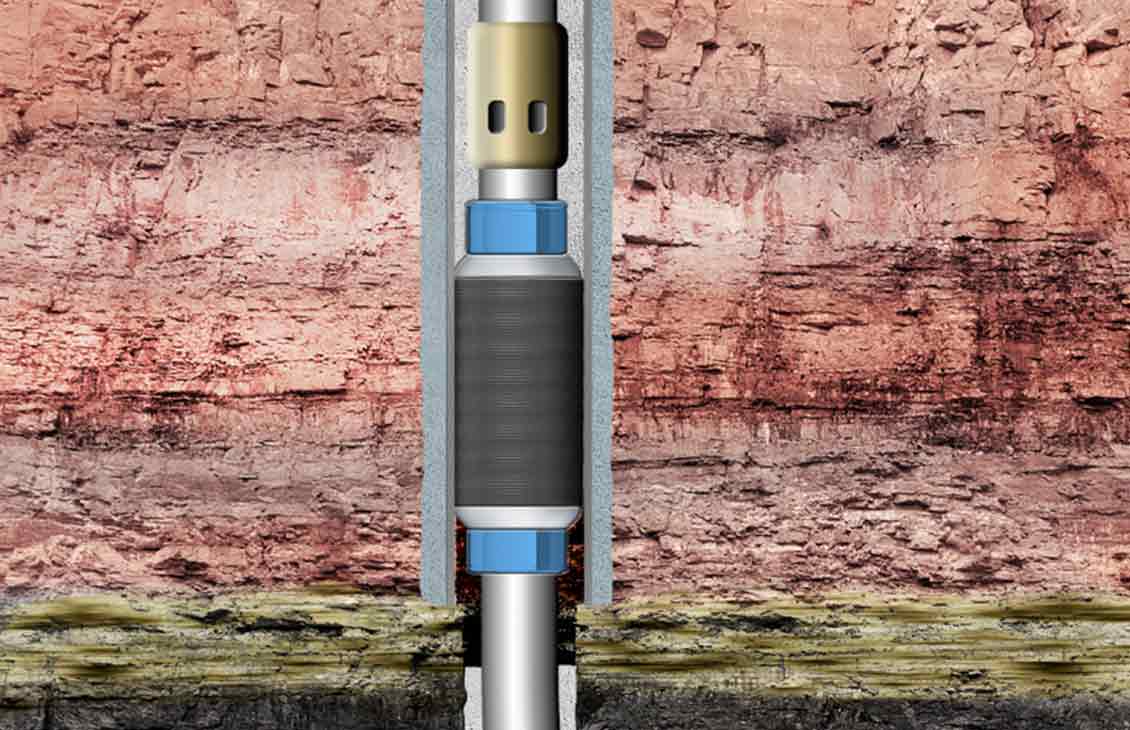

Minimize costs and NPT with robust, high-pressure expandable steel annular packers that rapidly isolate zones, even in oval boreholes. View

Set at low pressures to achieve zonal isolation. View