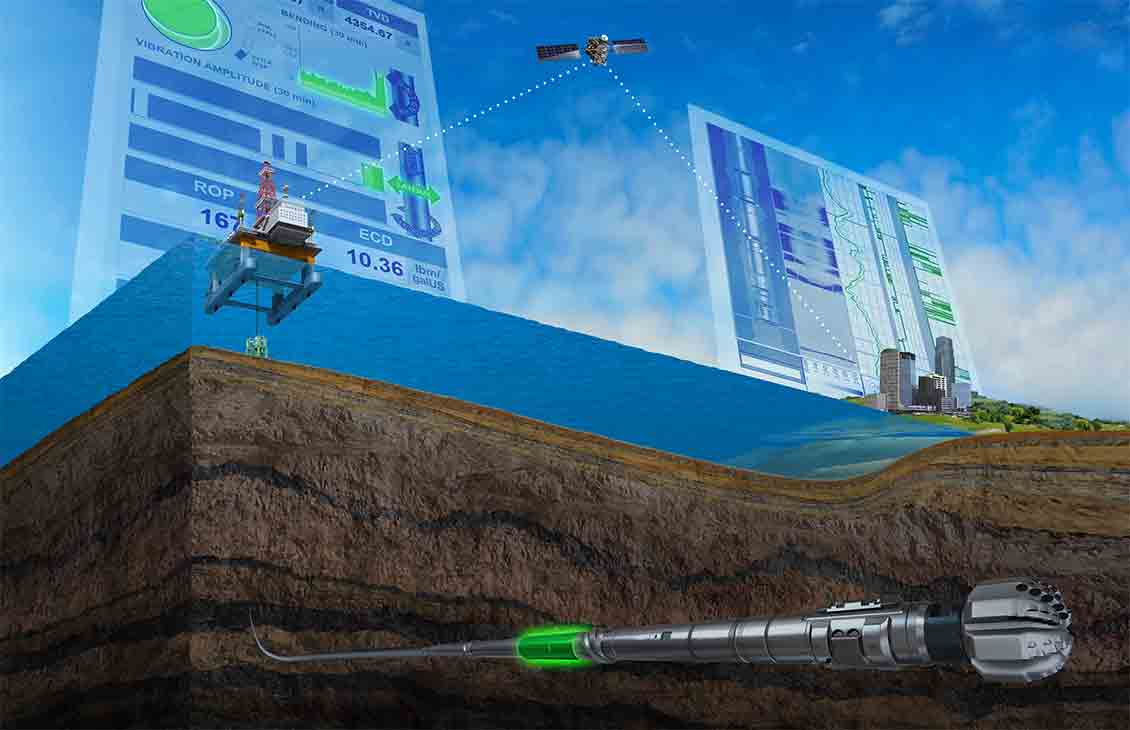

Measurement-while-drilling services

Surveying and telemetry technologies and services for drilling optimization

Beyond direction and inclination data, formation evaluation, and more, MWD services play a key role in driving drilling optimization and efficiency by minimizing invisible lost time and ensuring no ROP limitation occurs while drilling because of data transmission rates.

Obtaining measurements while drilling enables operators to save time by acquiring formation evaluation and drilling optimization data, which also helps minimize doglegs. Fit-for-purpose MWD services provide continuous direction and inclination measurements to guide geosteering and provide data for survey management and development planning.

When combined with the Orion II data compression platform, SLB MWD services can achieve up to 100-bps transmission rates.

Drilling Applications

High-speed, HPHT, slimhole, gyro-while-drilling, and retrievable technologies that bring more reservoirs within reach.

-

TruMax

Unconventional dual MWD serviceDrill more quickly and accurately in harsh unconventional formations and conditions.

-

Stream

High-speed intelligent telemetryStream high-speed intelligent telemetry provides real-time downhole data at any depth.

-

GyroLink

Definitive gyro-while-drilling serviceThe definitive choice for optimal borehole quality with surveying times 75% faster than conventional surveys.

-

TruLink

Definitive dynamic survey-while-drilling serviceAchieve real-time, high-definition wellbore architecture—from tophole to TD.

-

GyroSphere

MEMS gyro-while-drilling serviceSurvey at any inclination, at any depth, and at higher latitudes without changing batteries or recalibrating between runs.

-

xBolt G2

Accelerated drilling serviceDrill faster and more accurately using three downhole telemetry options, all in one BHA.

-

TeleScope ICE

UltraHT measurements-while-drilling serviceReceive critical downhole data from ultraHT wells with a high-speed telemetry service built to operate at ultrahigh temperatures.

-

TeleScope

High-speed telemetry-while-drilling serviceSimultaneously transmit multiple datasets with high-speed measurements while drilling.

-

DigiScope

Slimhole measurements-while-drilling serviceGenerate power for more tools and transmit high-quality data in slim holes.

Drilling Optimization

Real-time ahead-of-the-bit, monitoring, management, and seismic data services for better decisions while drilling.

-

NeoLink

Real-time downhole wired drillpipe controlAccelerate surface and downhole interactions to ensure a more sustainable well construction operation.

-

OptiDrill

Real-time drilling intelligence serviceManage downhole conditions and BHA dynamics while drilling using actionable, integrated data displayed on a rigsite dashboard.

-

OptiWell

Well construction performance serviceMonitor and analyze processes and downhole conditions in real time.

-

Suppressor dampening tool

Absorb and reduce torsional vibrationImproving BHA tool reliability while enabling PDC cutters to stay sharp for faster, longer drilling.

-

Shock Sub

Impact and vibration reduction toolReduce impact loads produced during milling and drilling operations, increase ROP, and extend equipment life.