M-I Swaco drilling fluids systems and additives

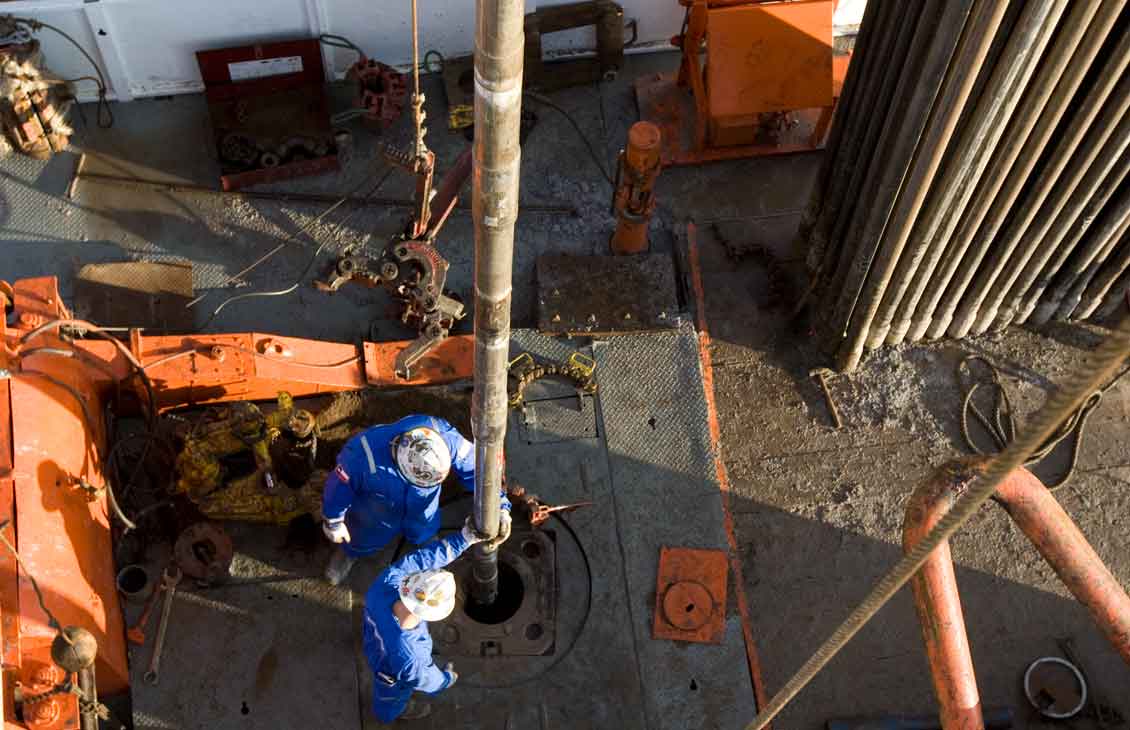

Powering performance in well construction

Increase production by minimizing formation damage

HydraGlyde™ water-based drilling fluid system delivers high-performance drilling with enhanced shale inhibition and torque reduction for superior wellbore stability and improved rates of penetration.

Recover more, waste less with high-performance shakers

The Mongoose Pro™ dynamic dual-motion shaker and MD-3™ triple-deck shaker support high separation efficiency and consistent drilling performance.

Extending screen life and cuttings separation

Extreme-life shaker screens composite shaker screens deliver long-lasting performance across a wide range of drilling conditions.

Recovering value from used drilling fluids

Preparing cleaner wellbores with completion-ready fluids

Clear-brine systems and Smart 4D™ displacement strategy technologies help remove debris, enable cleaner wellbores, and support efficient transitions into completion operations.

Find the right technologies to support your well construction and completion needs

Solids control technologies

High-efficiency surface equipment that preserve drilling fluid quality, improve cuttings removal, and reduce dilution and waste handling in complex wells.

-

Shakers

M-I SWACO technologyConsistently high-quality solids control performance—on land or offshore.

-

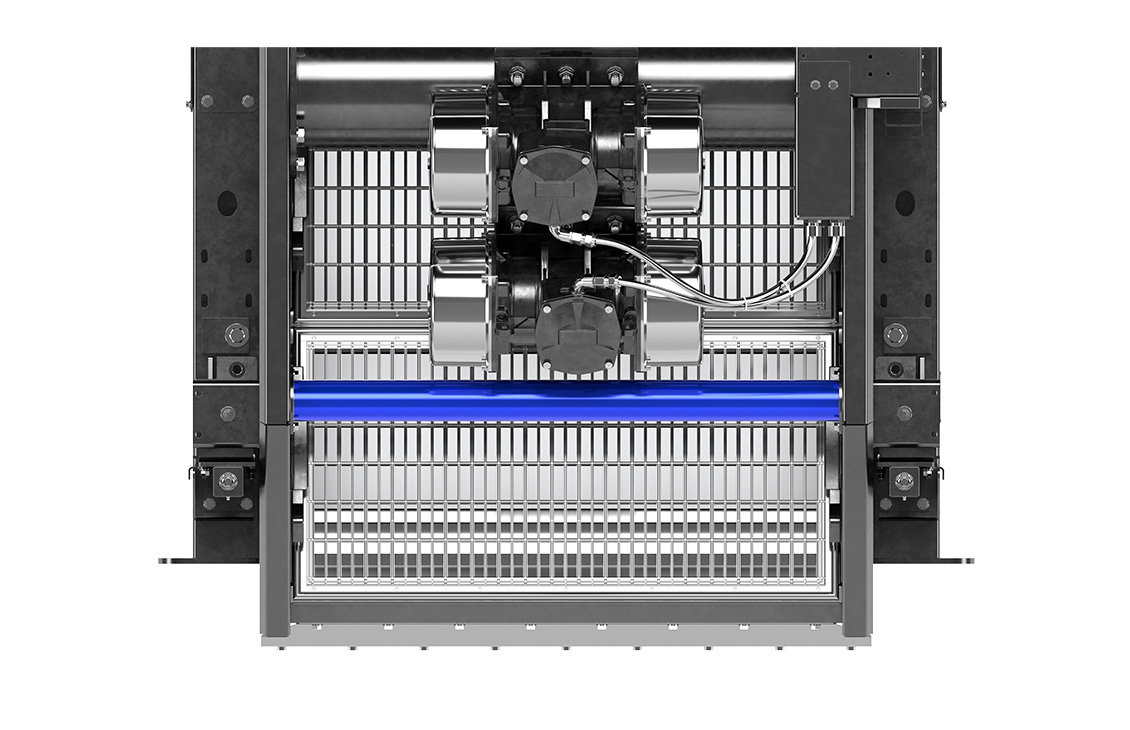

MONGOOSE PRO

Dynamic dual-motion shakerShift from balanced- to progressive-elliptical motion without suspending or shutting down operations.

-

MD-3

Triple-deck shakerMeet objectives for efficiency, flexibility, and rig space with an adaptable shaker in a compact package.

-

MONGOOSE Max

High-capacity shakerIncrease solids- and fluid-handling capacity by 35% and fluid recovery by 40%.

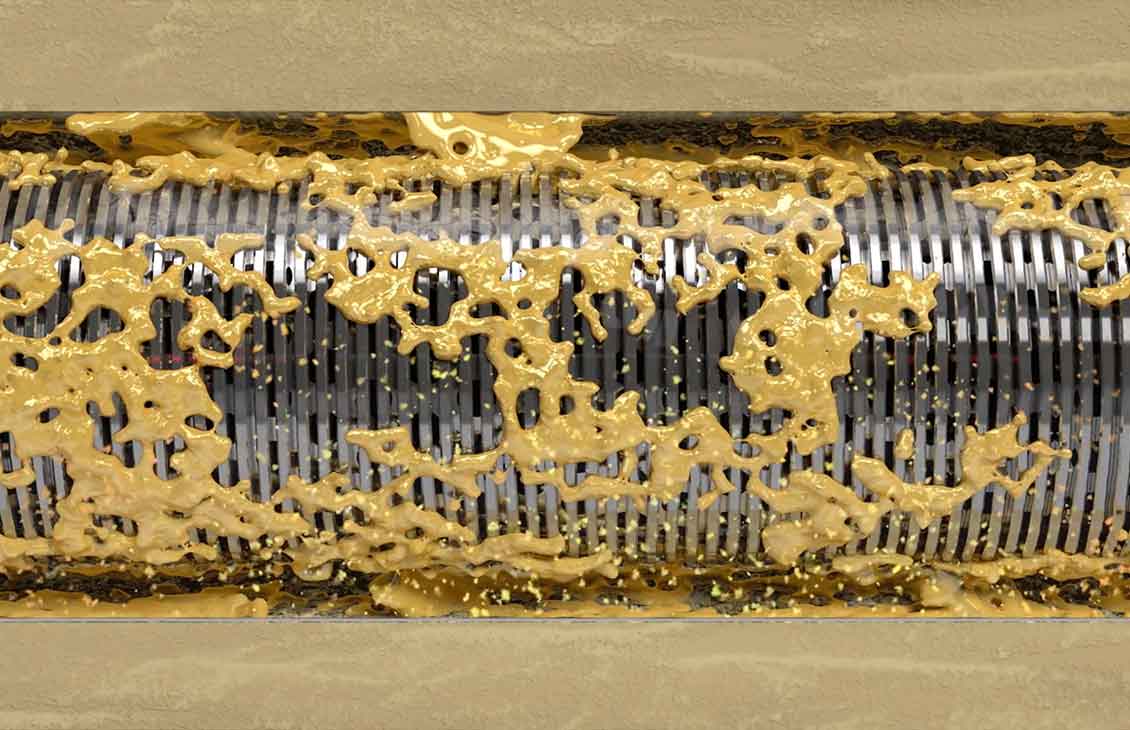

Shaker screens

Durable, high-capacity screens engineered to optimize solids separation efficiency and extend screen life across a wide range of drilling environments.

-

Shaker Screens

Exclusive lineReduce costs and waste volumes on shakers from M-I Swaco or third parties.

-

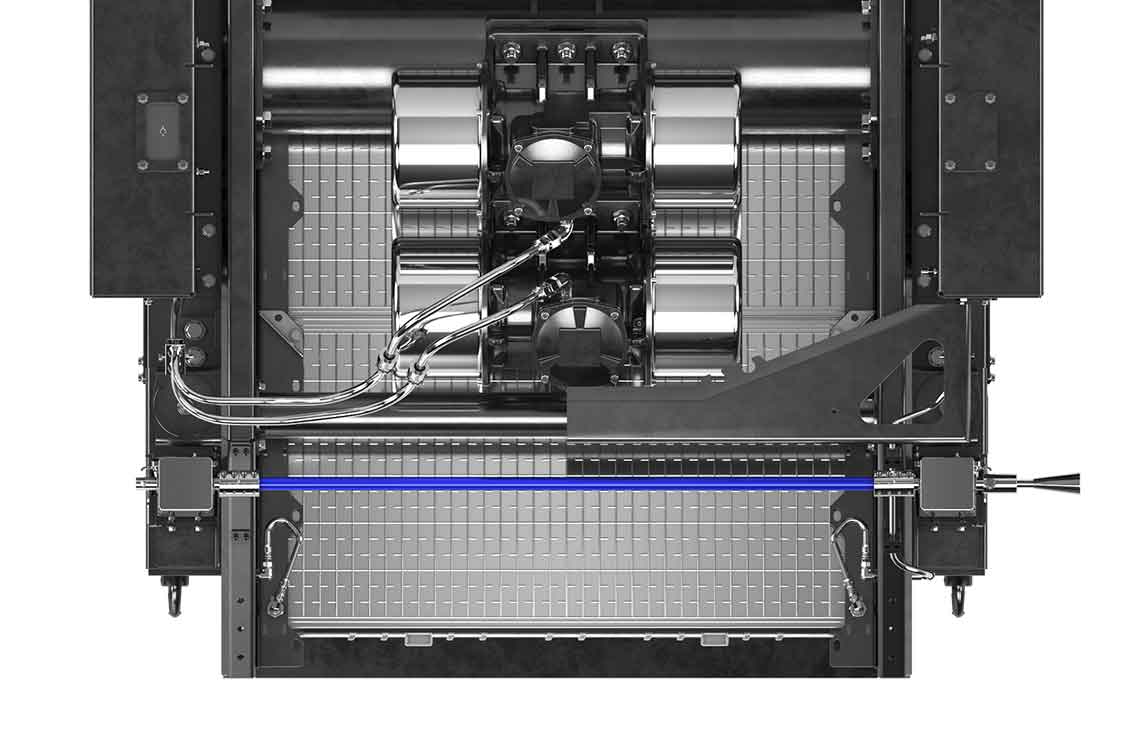

DURAFLO Optimus

High-capacity two-tier composite shaker screensThe most rugged, long-lasting, and efficient screens available.

-

Extreme-life shaker screens

Durable and longer-lasting screensExtreme-life shaker screens are durable and longer-lasting, reducing downtime, and fuel costs from fewer trips to landfills for a reduced CO2 footprint.

Centrifuges

High-performance centrifuges designed to recover valuable drilling fluid, control low-gravity solids, and support stable wellbore conditions while reducing costs.

-

Centrifuges

High-volume, high-speed unitsEnhance environmental performance.

-

CD-500 HV

High-volume, high-speed precision-balanced centrifugeSimplify solids control with a rotating stainless steel bowl and a single-lead spiral-screw conveyor inside that rotates at a lower rpm.

-

RHE-USE

Two-stage centrifuge systemRemove low-gravity solids and produce clean fluid for reuse in drilling systems.

Drilling fluids solutions

Comprehensive water-based and oil-based drilling fluid systems and performance additives engineered to maintain wellbore stability, manage pressure, reduce fluid losses, and optimize drilling performance across complex formations.

-

Drilling fluid solutions, systems, and products

Customized fluid systems and associated additivesImprove efficiencies, reduce costs, and minimize HSE impact in demanding applications, including HPHT, deepwater, and depleted wells.

-

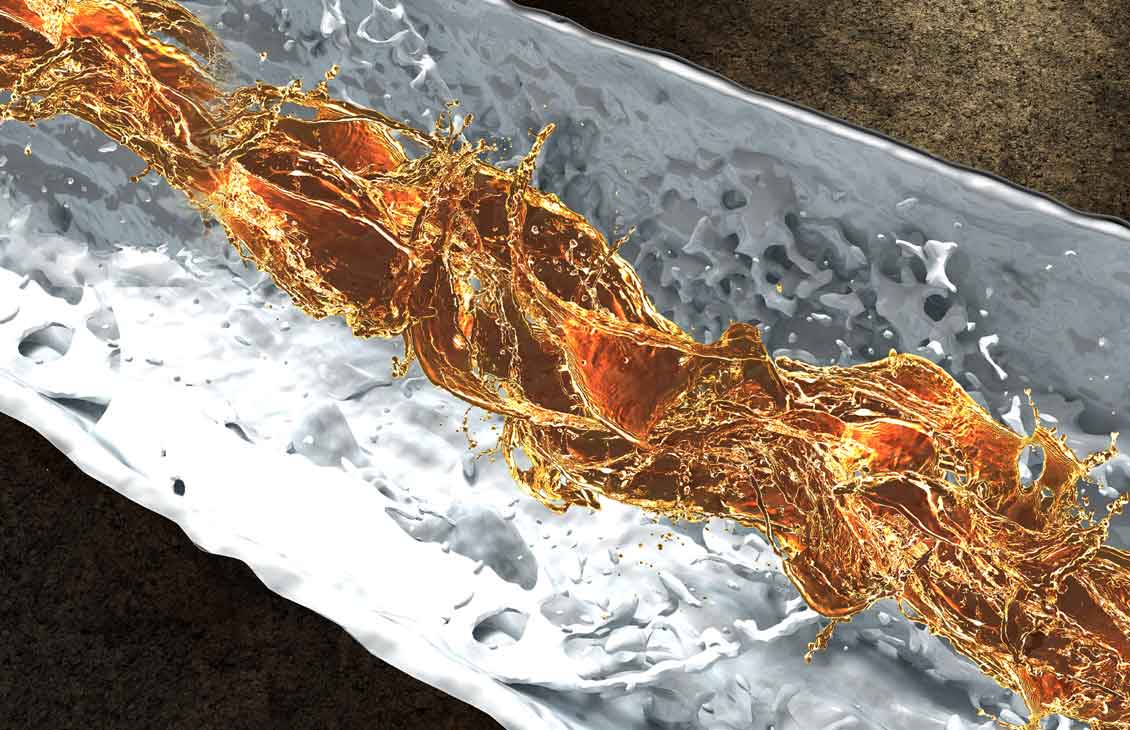

HydraGlyde

High-performance water-based drilling fluid systemReduce torque, drag, shale swelling, and dispersion in environmentally sensitive shale.

-

KLA-SHIELD

Enhanced-polymer water-based drilling fluid systemMeet a variety of drilling challenges—large-diameter wellbores, extended-reach drilling, and highly reactive shales.

-

UltraDril Plus

Premium-performance aqueous drilling fluid systemBalanced fluids for performance, economics, and sustainability in challenging drilling environments

-

VERSACLEAN

Mineral oil–based drilling fluid systemCut costs and bolster environmental compliance.

Completion fluids

Formation-compatible clear brines and additives engineered to control reservoir pressure, minimize formation damage, and support reliable completion operations.

-

Fluids and Tools

Reservoir drill-in fluids, additives, cleanup tools, and filtrationAccelerate and maximize production throughout the drilling, workover, and completion processes with minimal HSE impact.

-

Clear Brines

Minimally damaging completion brinesMinimize formation damage and control reservoir formation pressures with halide and formate brines and additives.

Wellbore cleaning tools

Specialized mechanical cleaning that remove debris, improve displacement efficiency, and deliver clean, completion-ready wellbores across all hole sizes and well conditions.

-

Wellbore Cleaning Tools

Mechanical precompletion wellbore cleanup solutionsEfficiently remove mud residue and other debris to deliver an unobstructed wellbore for the completion.

-

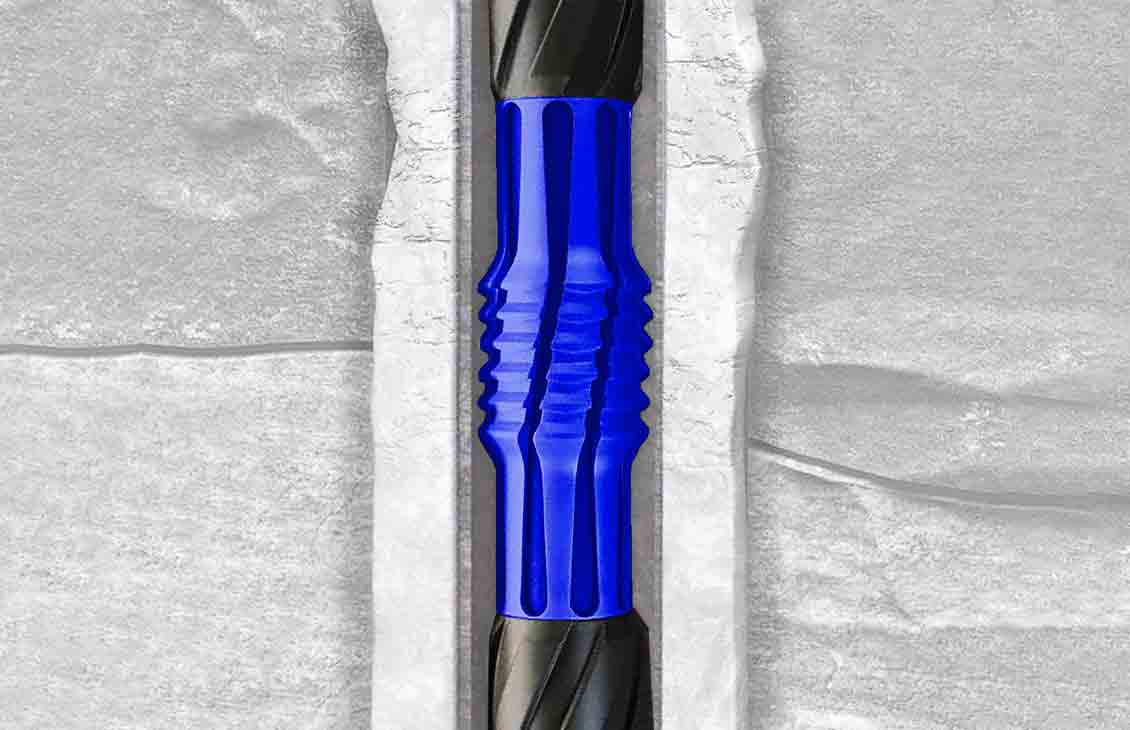

RAZOR BACK

Casing cleaning toolProvides effective wellbore cleanup.

-

WELL DEFENDER

Multiactivation drilling valveDelivers specialized lost circulation materials (LCMs) and preventative borehole stress treatments

Reservoir drill-in fluids (RDFs)

Low-damage, formation-friendly drill-in fluids engineered for openhole completions that require fluid compatibility and minimal impairment to reservoir productivity.

-

Reservoir Drill-In Fluids

Minimally damaging fluids for reservoir drilling and openhole completionsMinimize formation damage with completion-compatible reservoir drill-in fluids and associated additives.

-

FLOPRO NT

Water-based reservoir drill-in fluidMeet the needs of reservoir engineers and drilling personnel while minimizing environmental impact and increasing ROP.

-

DIPRO

High-density divalent reservoir drill-in fluidGenerate low filtration rates and produce a thin filtercake with the first biopolymer-free divalent brine-base RDF.

-

VERSAPRO

Invert-emulsion reservoir drill-in fluid systemMinimize formation damage problems in high-temperature, low-permeability, openhole-completed reservoirs.

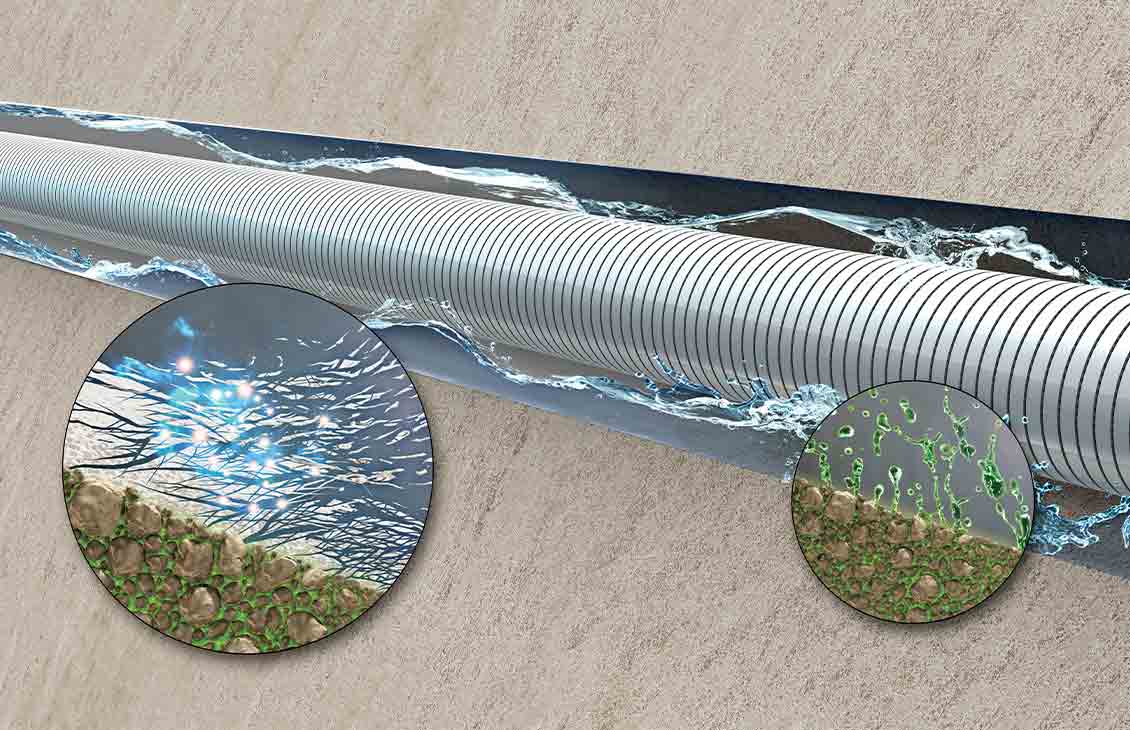

Filtercake breakers

Chemistries designed to remove filtercake uniformly and efficiently, ensuring cleaner production pathways in openhole completions.

-

Filtercake Breakers

Removal of filtercake in openhole completionsPrepare your openhole completion for uniform production by tailoring filtercake breakers to your well.

-

FAZE-OUT

Reversible-system water-based filtercake breakerDissolve reversible invert-emulsion filtercakes behind premium screens and openhole gravel packs.

-

D-STRUCTOR HD

Organic acid precursorSlowly release organic acid to minimize losses and achieve uniform filtercake removal.

Intervention fluids

Specialized fluids that support safe and effective well intervention operations by reducing debris, managing flow path cleanliness, and enabling efficient workovers.