Infill Well Optimization

Maximize the returns from your infill well investments by harnessing the power of fit-for-purpose technologies and digital workflows

Infill drilling accounts for more than 60% of the new wells drilled in North America, making it more important than ever to follow a consistent and holistic process of planning, designing, constructing, completing, and producing them.

Infill drilling sparks changes for operators

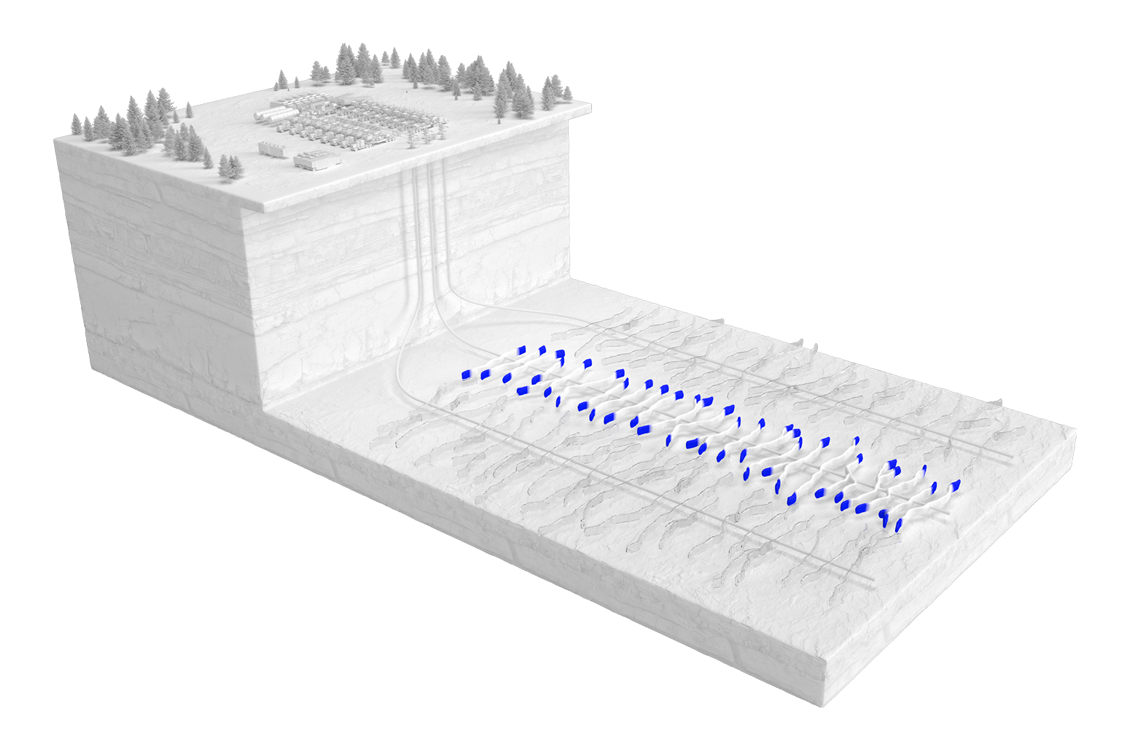

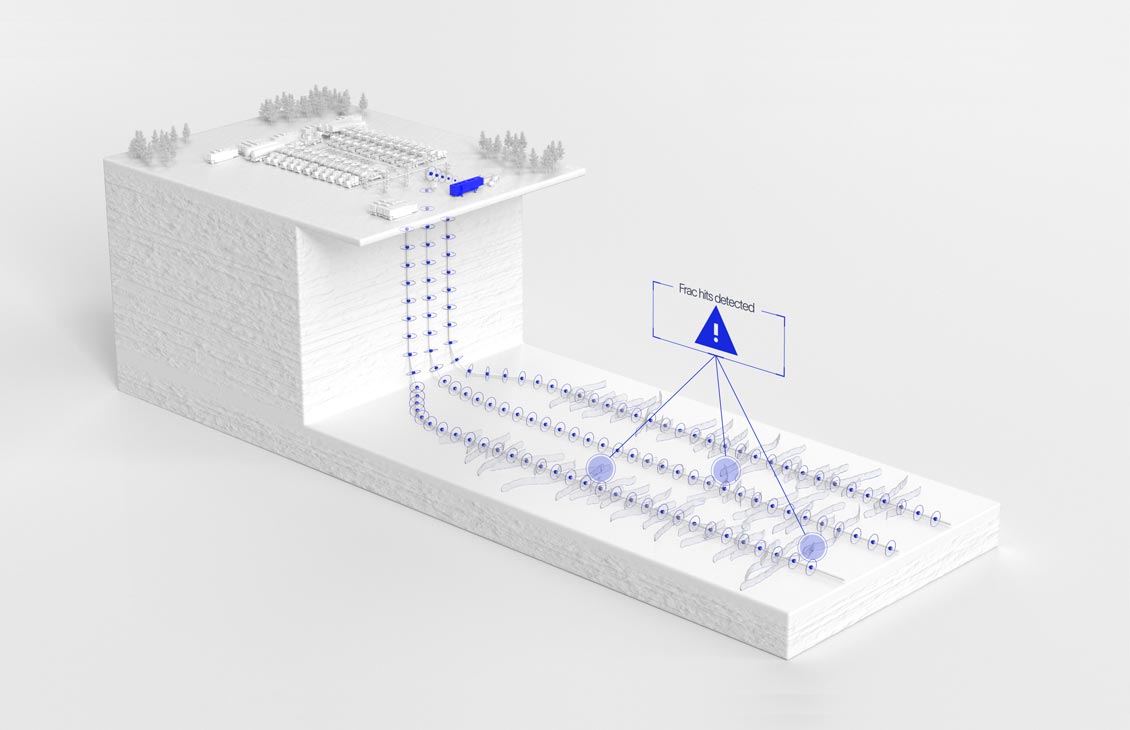

In most US unconventional basins, operators start development by drilling the minimum number of wells needed to hold their acreage. These initial wells are sometimes called parent wells. Operators then start drilling infill wells, also called child wells. When the child well stimulation operation communicates with a parent well, the result is parent-child well interference or a frac hit.

Frac hits can have positive, negative, or neutral effects on parent well production. In addition, infill well production varies with distance from the parent, time elapsed since the parent began producing, and other factors. Rapid production declines can also occur in parent and child wells after infill well stimulation.

Pay it Forward Webinar Series: Infill Wells (Part 1)

Learn about minimizing losses during well shut-in and restart operations.

Download the webinarParent production affects child fractures—and productivity

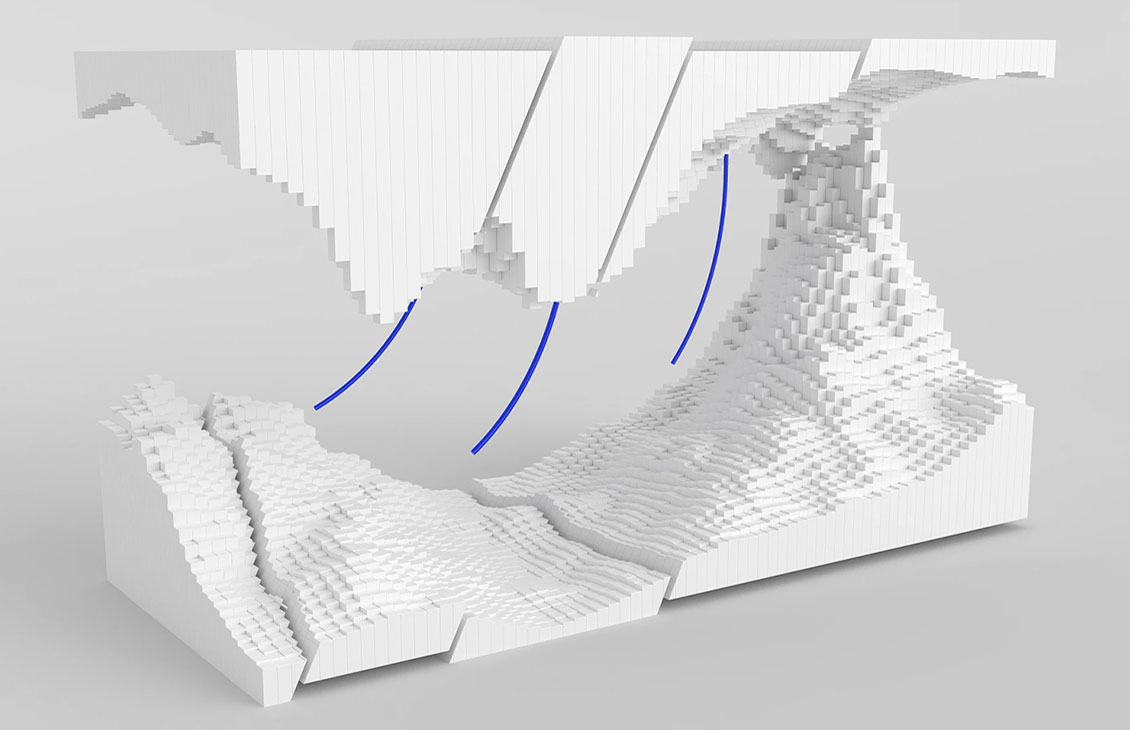

The point of infill drilling is to replace reserves as parent well production declines. But the parent well’s production depletes the reservoir, and the reduced reservoir pressure tends to reduce formation stresses, attracting new hydraulic fractures from nearby infill wells.

If a new well is too close to the parent well, its fractures will grow asymmetrically toward the lower stress, creating a drainage area that largely overlaps the area already depleted by the parent well. Thus, the child well’s initial production will be markedly lower than that of the parent well, and it will decline faster.

Differences in experiences by play exacerbate the challenge of optimizing the field and individual well designs.

World Oil Webcast Replay

In case you missed it: Learn about best practices for developing and extending unconventional fields with infill wells.

Watch the webcastInfill well best practices across North America

Williston Basin

Factors for success in North Dakota, US, and Saskatchewan and Manitoba, Canada.

Infill planning

-

DrillPlan Solution Improves Well Planning Efficiency by More Than 50%, Williston Basin

Petro-Hunt uncovers opportunities for drilling risk mitigation and well design innovation.

-

A New Method of Acquiring Openhole Logs In Unconventional Wells

Recently developed conveyance and acquisition system greatly reduces costs and risks.

-

Case Study of a Landing Location Optimization within a Depleted Stacked Reservoir in the Midland Basin

Comprehensive assessment and clear recommendations for challenging partially depleted stacked pay interval.

-

Frac Hits: Good or Bad? A Comprehensive Study in the Bakken

Case studies from the Bakken, carefully considering all the physics, rock, and fluid interaction in the subsurface strata.

Infill construction

Infill execution

-

BroadBand Sequence Service Stimulates Wells with 50% Less Diverter Material, Bakken Shale

High-pressure injector technology and large-particle diverter pills reduce job time.

-

BroadBand Sequence Service Contributes 42% of Total Oil Production in Well for Whiting Petroleum

Fracturing service stimulates uncemented 1,822-ft section, treats 17% of lateral length, Williston Basin.

-

Lime Rock Resources Prevents Frac Hits and Increases Parent and Infill Well Production

Optimized stimulation services boost parent well production by 150% and infill well average by 66% over the parent, North Dakota.

-

Increased Reservoir Contact in Cemented Multistage Completions Using Engineered Diversion Workflow

New sequenced fracturing technique further increases reservoir contact, Williston Basin.

-

Stimulation Optimization Using Engineered Diversion Workflow to Increase Wellbore Contact in Cemented Completions

Completion techniques in the Middle Bakken formation have evolved over the years, with cemented Plug & Perf becoming the most common technique in recent years. It relies on stimulation of multiple clusters of perforations, normally 3-5, at one time.

-

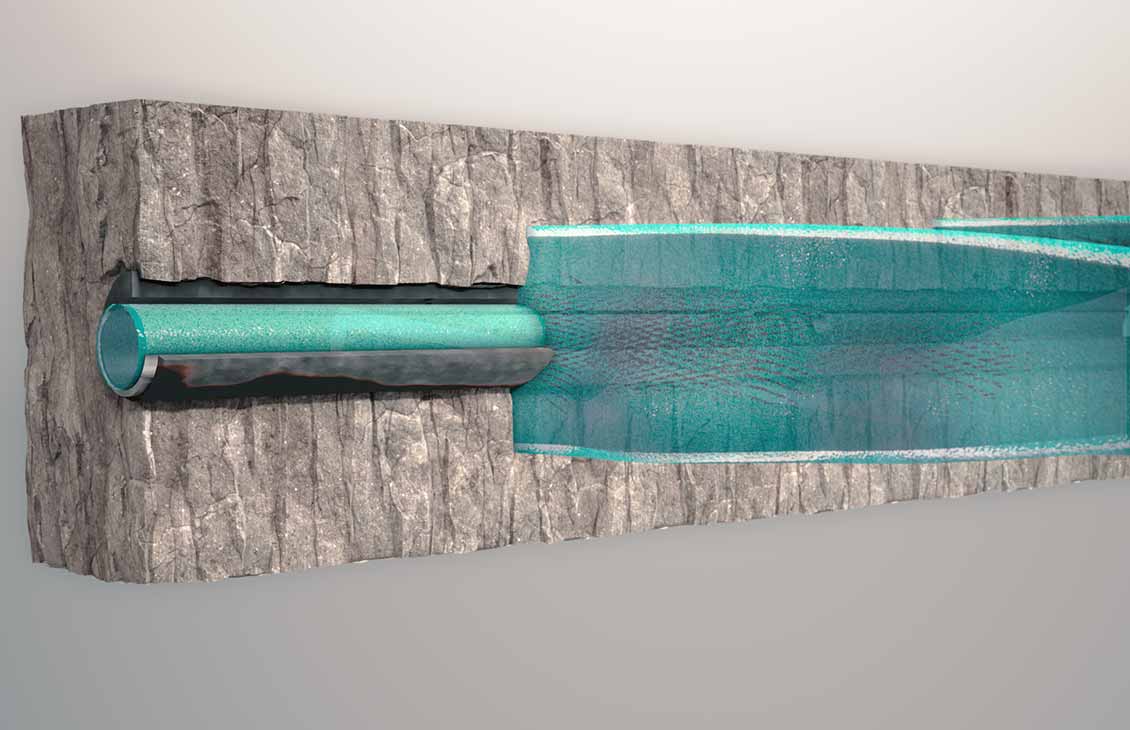

Understanding and Mitigating Depletion Effects in Infill Wells for Optimized Production

Fracture geometry control reduced frac hits as confirmed by high-frequency pressure monitoring.

-

Application of Novel Fracture Geometry Control Solution in Williston Basin

Increase proppant placement around infill wells and prevents fracture interference.

-

Innovative Approach to Effectively Stimulate Openhole Sections of Horizontal Laterals

Design methodology, execution details, and production results from Williston Basin.

-

Fracture Geometry Control Technology Prevents Well Interference in the Bakken

The increasing trend of drilling infill wells (more than 60% of new wells in 2017) comes with the significant risk of well interference.

Infill recovery

-

REDA Continuum Stages Extend Flow Rate Range, Saving Operator USD 185,000 in Unconventional Well

Engineered REDA Maximus ESP system manages steep production decline to achieve 82% drawdown in the Bakken Shale, North Dakota.

-

REDA Maximus ESP System with REDA Continuum Stages Increases Run Life by 500% in the Bakken Shale

Customer experiences continuous production down to 200 bbl/d using one ESP system.

-

REDA Maximus Systems with REDA Continuum Stages Increase Production by 70% in the Bakken Shale

Customer increases production while avoiding ESP replacement and related costs.

Permian Basin

Factors for success in the Midland Basin and Delaware Basin of West Texas and southern New Mexico.

Infill planning

-

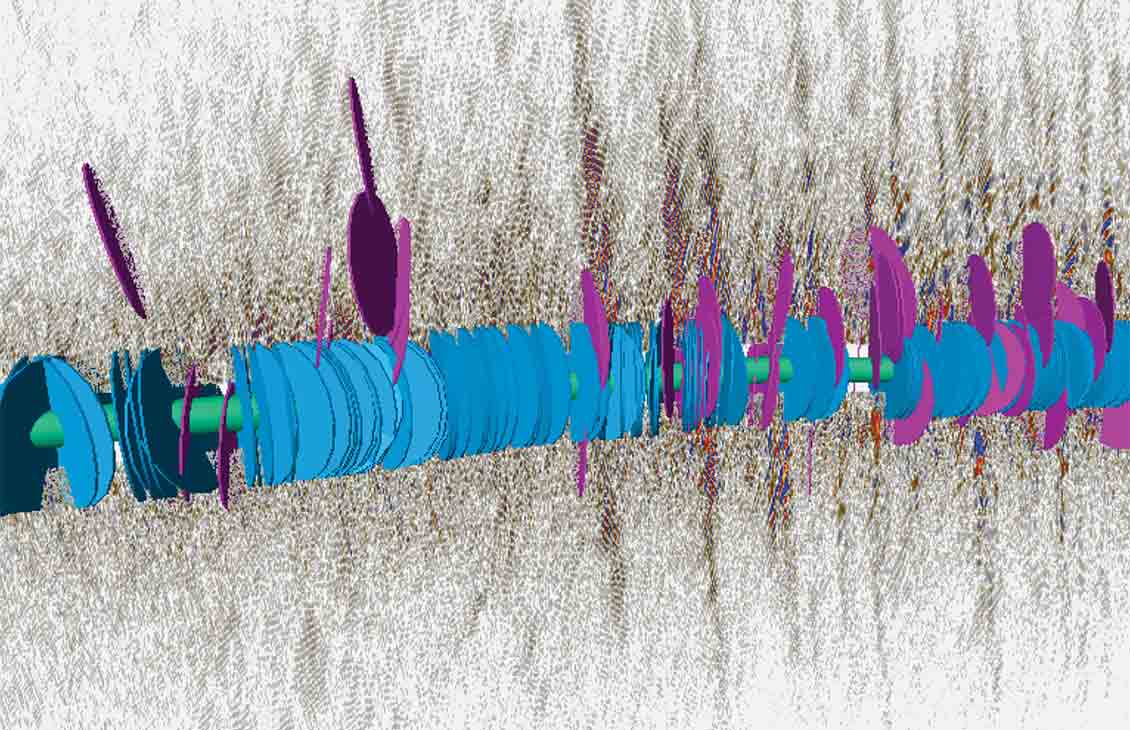

3D Far-Field Sonic Service Maps Natural Fractures to Improve Stimulation, West Texas

Workflow combines high-resolution sonic and resistivity imaging for optimizing completion design and hydraulic fracturing.

-

3D Structural and Properties Modeling Using Limited Datasets Leads to Optimized Completion Design

Overcome casing size limitations and determine ideal targets based on geomechanical properties.

-

Engineered Completion Design Increases Reservoir Contact and Productivity in the Wolfcamp Shale

Mangrove stimulation design uses log measurements to intelligently place perforation clusters in optimal intervals of high-pressure shale play.

-

Microfracture Tests Directly Measure Geomechanical Properties in the Avalon Shale, Delaware Basin

MDT tester, fracture injection tests, and sonic logs confirm minimum horizontal stress.

-

Producible Hydrocarbons Identified in Low-Resistivity Reservoir by Combining Litho Scanner Service and NMR

TOC from Litho Scanner spectroscopy service and NMR pore-size distribution identify the sweet spot for optimal horizontal landing. point, Bone Spring Sand.

-

Impact of Well Spacing and Interference on Production Performance in Unconventional Reservoirs, Permian Basin

The impact of different well spacing configurations on well interference and production performance.

-

Advanced Modeling of Production Induced Pressure Depletion and Well Spacing Impact on Infill Wells in Spraberry, Permian Basin

How changes in well spacing and proppant volume will impact new infill well performance.

-

Calibrated Complex Fracture Modeling Using Constructed Discrete Fracture Network from Seismic Data in the Avalon Shale, New Mexico

Successful application of seismic data and DFN for modeling hydraulic fractures in unconventional reservoirs.

Infill design

-

FMI-HD Microimager Identifies Vugs and Fractures in High-Resistivity Carbonate, Permian Basin

Secondary porosity features and natural fractures obtained across dynamic resistivity range.

-

Slim Cased Hole Lithology and Anisotropic Mechanical Properties with One Toolstring, West Texas

No rig required for obtaining a complete dataset in a horizontal well by tractor conveyance of Pulsar spectroscopy service and ThruBit Dipole acoustic service.

-

Integrated Completion with ShalePrime Service Raises Oil Production by 70% for Manti Tarka Permian

Combining modeling, rock-fluid compatibility testing, and efficient OneStim services reduces stimulation costs, Permian Basin.

-

An Integrated Workflow for Completion and Stimulation Design Optimization in the Avalon Shale, Permian Basin

Applying a multidisciplinary integrated workflow to a horizontal well to model complex hydraulic fractures and production.

Infill construction

-

Fulcrum Technology Improves Cement Bond Index by 55% in Horizontal Wells, Permian Basin

Cement-conveyed frac performance technology efficiently mitigates hole-cleaning challenges by altering mud mobility—without special equipment or cement designs.

-

Fulcrum Technology Increases Liquids Production up to 41% in the Permian Basin

Minimizing interstage communication during hydraulic fracturing treatment results in higher normalized 3-month cumulative production.

-

Fulcrum Technology Stops Pressure Communication through Cement Samples in Lab-Scale Testing

Fulcrum technology changes rheology in cement mud channels to prevent fluid movement.

-

Effective Zonal Isolation in Horizontal Wells: Mitigating Negative Impact of Mud Channels

Preliminary results of field testing of new cement system that improves zonal isolation.

Infill execution

-

BroadBand Sequence Fracturing Service Increases Production 42% in Wolfcamp Shale

Composite fracturing fluid maximizes wellbore contact in highly laminated and pressured unconventional reservoir in Permian basin, southern USA.

-

BroadBand Services’ Composite Fracturing Fluid Improves Production 62% from Thick Shale

Better proppant transport and increased vertical conductivity make better wells in the Wolfcamp Shale, Permian basin.

-

Permian Producers Lean on Technology

During the industry downturn, operators tend to fine-tune efficiencies to drive down costs.

-

Multigeneration Section Development in the Wolfcamp, Delaware Basin

Proactive approach of designing, monitoring, and responding to shale wells.

Infill recovery

-

Devon Energy Minimizes Flowback Completion Damage by Following the Recommended Secure Operating Envelope

AvantGuard services guides poststimulation operations, Permian Basin.

-

Stopping the Sand

The best way to manage solids production is by optimizing the initial completion.

-

Lift IQ Service Improves ESP Efficiency and Reduces Deferred Production in Permian Basin Fields

Real-time surveillance service monitors downhole pump performance and enables improved production and pump uptime in two unconventional fields.

-

Lift IQ Service Remote Interventions Deliver 91% ESP Uptime in the Permian Basin

Surveillance and optimization avert 1,800 bbl of deferred oil production and 800 hours of field service in just 3 months.

-

Pioneering Completion and Production Techniques for Unconventional Plays in the Permian Basin

Established operators in the Permian Basin have been producing from legacy mature fields and formations for many years with vertical wells, but the focus has shifted to aggressive growth in new unconventional resource plays. With this shift, a majority of the players have transitioned their programs to horizontal wellbores with multistage completions.

Eagle Ford Shale

Factors for success in South Texas.

Infill design

-

630-bbl/d Oil After Fracture Evaluation of Eagle Ford Carbonate Section

FMI microimager, Sonic Scanner platform Stoneley data, and CMR-Plus magnetic resonance in one trip.

-

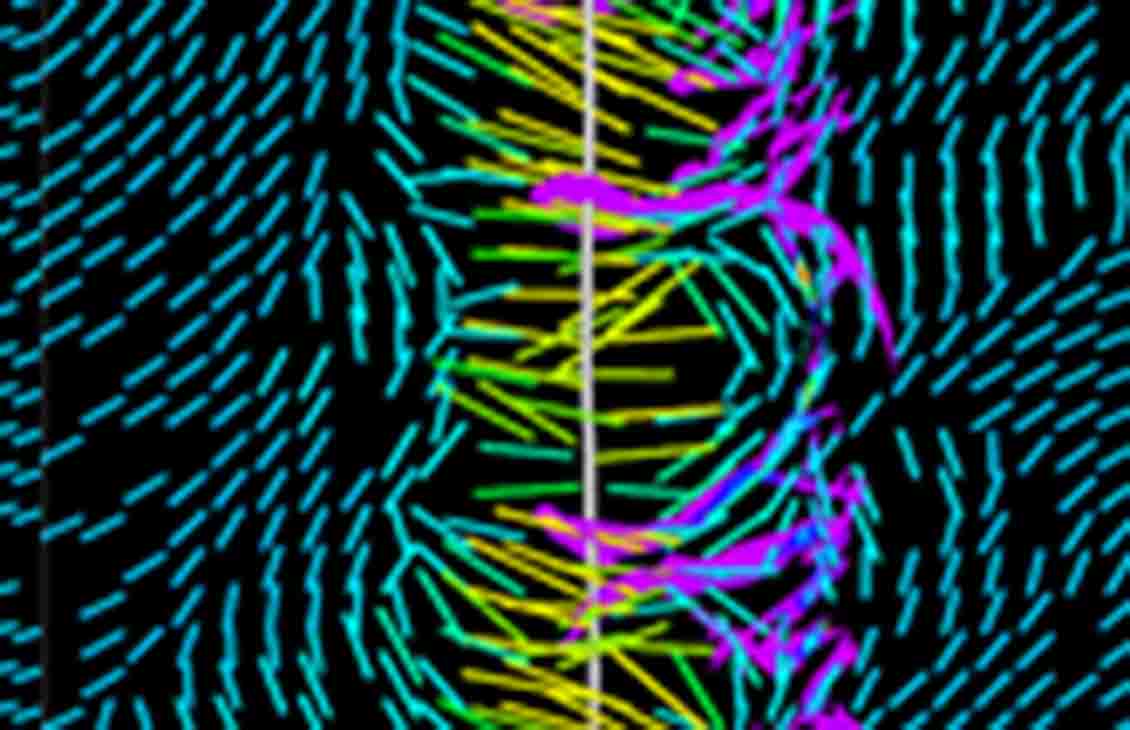

Engineered Completions Improve Eagle Ford Perforation Efficiency 28%

Open- and cased hole logging used to optimize positioning of fracture stages and perforation clusters for more efficient production from horizontal wells.

-

Through-Bit Logging Optimizes Shale Completions

One of industry’s greatest challenges in unconventional plays–especially at today’s oil prices–lies in designing completions that increase production significantly while simultaneously controlling costs.

-

Geoengineered, Integrated Well Program Improves Oil Production by 80%–86%

Combining ThruBit services, Kinetix software, and BroadBand Sequence service increases production for Lonestar Resources in the Eagle Ford Shale.

-

Kinetix Stimulation-to-Production Software Increases Production by 40% in Eagle Ford Shale

Operator reduces completion costs by 11% with integrated stimulation design and modeling.

-

Reservoir Model Helps Plans for Infill Wells to Avoid Productivity Losses, Eagle Ford Shale

Integrated workflow helps optimize infill drilling in drill-to-hold leases by minimizing the occurrence of fracture hits and well interference.

-

Eagle Ford Completion Optimization Using Horizontal Log Data

Value of acquiring petrophysical data in the lateral section and its application to completion optimization.

-

Eagle Ford Completion Optimization Strategies Using Horizontal Logging Data

Results of the study can change the way unconventional resources are developed.

-

Application of Reservoir-Centric Stimulation Design Tool in Completion Optimization for Eagle Ford Shale

Completion design for unconventional shale plays in North America is a topic of high current interest. Although the practice of stimulating shale horizontal wells with large slickwater treatments is slowly changing to the use of Hybrid/Crosslink treatments in certain plays, little has changed with the method of completion design itself.

-

A Novel Completion Method for Sequenced Fracturing in the Eagle Ford Shale

In multistage fracturing of unconventional formations, such as the Eagle Ford shale, wells are traditionally stimulated by fracturing several perforation clusters at once. While the technique is operationally efficient, there is evidence from production logs, microseismic monitoring and other measurements that several of the clusters produce below expectations or do not produce at all.

-

Engineering an Effective Completion and Stimulation Strategy for In-Fill Wells

As the oil & gas industry enters into next phase of unconventional reservoir development, many new in-fill wells will be drilled in various shale oil and gas plays in North America. A detailed evaluation to devise an engineered approach for stimulating and completing these wells is critical to maximizing productivity.

Infill execution

-

BroadBand Sequence Service Delivers 21% Increase in Productivity in the Eagle Ford

Fracturing service significantly increases stimulation effectiveness compared with conventional plug-and-perf technique.

-

BroadBand Sequence Service Increases Production in Refractured Well by 600 bbl/d

Schlumberger restimulates well, accesses new rock, increases reserves, and increases flowing pressure by 4,750 psi.

-

BroadBand Sequence Service Increases Productivity Index More Than 600% in Refractured Shale Well

Advanced sequenced fracturing service doubles oil and gas production rates while quadrupling flowing pressure, Eagle Ford Shale.

-

BroadBand Sequence Service Reduces Completion Time by 46% for Plug-and-Perf Operations, Eagle Ford

Fracturing service significantly enhances operational efficiency and reduces the number of bridge plugs required by 68%.

-

BroadBand Shield Service Improves Production by 12% in Infill Well and 5% in Parent Well

Aggressive engineered stimulation design maximizes infill production and avoids detrimental well-to-well communication, Eagle Ford Shale.

-

Invizion Evaluation Service Improves Zonal Isolation 70% in Eagle Ford Shale

Evaluation of near-wellbore communication and isolation of cemented BroadBand Precision service sleeves enhance well stimulation.

-

Engineering an Effective Completion and Stimulation Strategy for In-Fill Wells

As the oil & gas industry enters into next phase of unconventional reservoir development, many new in-fill wells will be drilled in various shale oil and gas plays in North America. A detailed evaluation to devise an engineered approach for stimulating and completing these wells is critical to maximizing productivity.

-

Sequenced Fracture Treatment Diversion Enhances Horizontal Well Completions in the Eagle Ford Shale

Extend interval length and increase effectively stimulated rock volume.

-

Far-Field Diversion Technology to Prevent Fracture Hits in Tightly Spaced Horizontal Wells

Intelligent engineering design, including a far-field diversion pill, corrects fracture growth geometry.

-

Optimization of Infill Well Development Using a Novel Far-Field Diversion Technique in the Eagle Ford Shale

In today's low oil price environment, the majority of operators are focusing on the development of their best acreage to maximize economic returns. These sweet spots are increasingly scarce, and hence the number of infill wells that will be drilled will increase.

-

Refracturing in the Eagle Ford Shale: One Operator's Quest to Identify and Rank Candidates, Minimize Well Interference, and Understand Variability of Results

One of the main objectives of a refracturing operation is to increase oil and gas production while avoiding the costs associated with completing a new well.

Infill recovery

-

AvantGuard Advanced Flowback Services Help Lonestar Determine Optimal Coiled Tubing Operating Conditions

Real-time monitoring with Vx Spectra surface multiphase flowmeter enables better preservation of fracture integrity, Eagle Ford Shale.

-

Lonestar Confirms Fracture Placement and Scaling Tendency with AvantGuard Flowback Services Monitoring

Similar geochemical fingerprints during flowback of all three wells indicate fractures contacted sections with the same bounding units and only minor scaling potential.

-

Customized ESP Solution Optimizes Operations in the Unconventional Eagle Ford Shale

SLB and Magnum Hunter Resources establish innovative ESP approach in new environment.

-

Shale Spotlight: Staying Ahead of the Curve

Real-time data has been instrumental for ESP operation, as well as enabling engineers to analyse the reservoir and assess well completion techniques and the influence of fractures from nearby wells.

-

Interrogating Flowback Chemistry for Damage Markers in the Eagle Ford

Workflow to generate an appropriately scoped, high-quality dataset to facilitate interpretation of subsurface phenomena.

Haynesville Shale

Factors for success in East Texas and northern Louisiana.

Infill design

-

Qualifying Diversion in Multi Clusters Horizontal Well Hydraulic Fracturing in Haynesville Shale Using Water Hammer Analysis, Step-Down Test and Microseismic Data

The objective of this study is to evaluate and maximize the effect of diversion in multi-cluster horizontal well hydraulic fracturing applications using water hammer profile analysis, step down test and microseismic monitoring.

-

Proposed Refracturing Methodology in the Haynesville Shale

During the downturn in the oil and gas industry, many operators have chosen to refracture their previously underperforming wells to boost economics with lower investment compared to drilling new wells.

-

Unique Multidisciplinary Approach to Model and Optimize Pad Refracturing in the Haynesville Shale

Understanding the viability of refracturing and its influence on existing fracture networks.

Infill execution

-

Comstock Uses BroadBand Sequence Service to Increase Gas Rate 700% in Haynesville Shale Well

Refracturing improves immediate and short-term production of natural gas well.

-

BroadBand Sequence Service Boosts Flowing Pressure by 300%

Fracturing service restimulates previously fractured well, accesses new rock, and increases revenue.

-

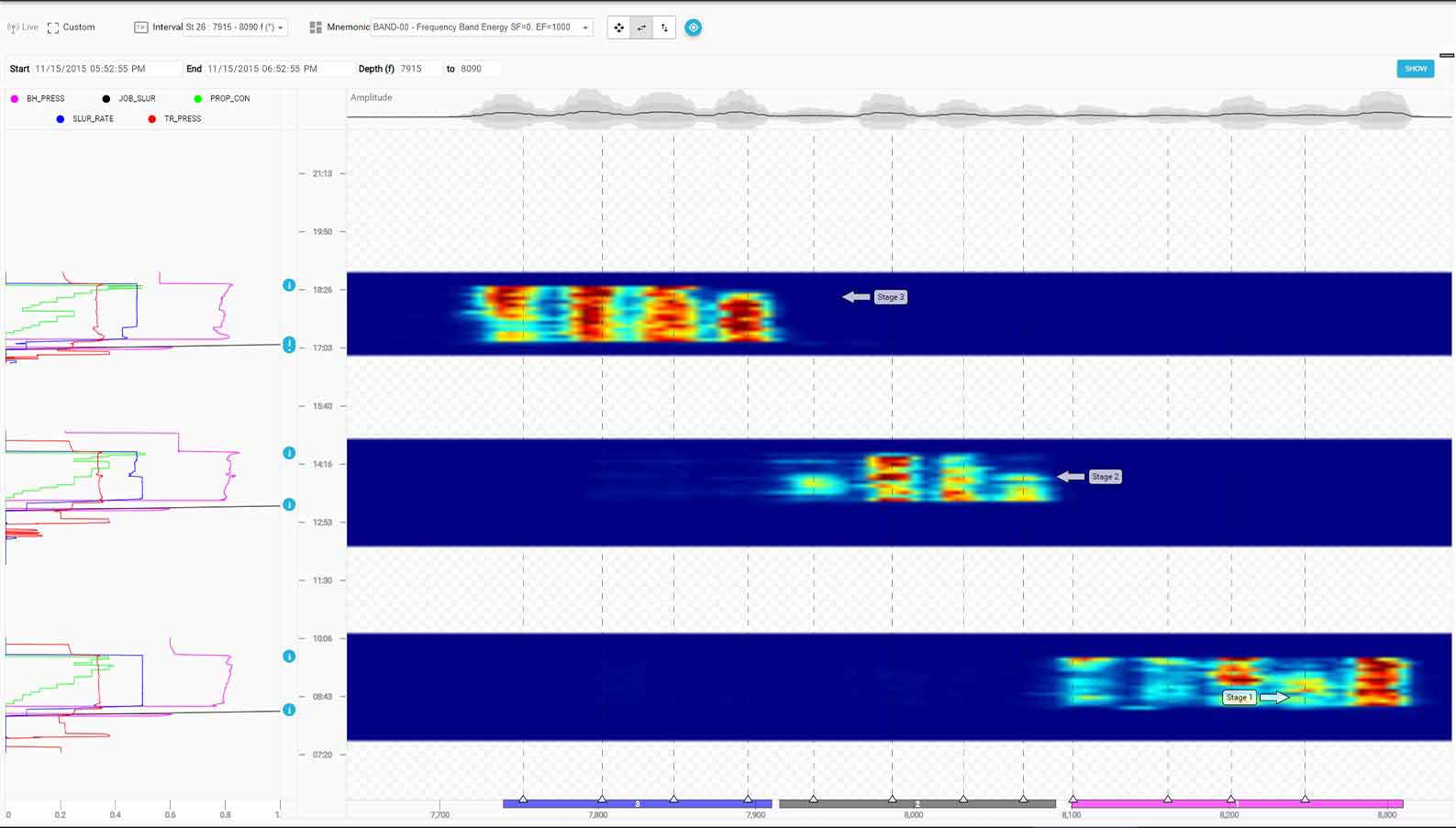

WellWatcher Stim Service Verifies Diversion and Stimulation Delivery in Limited-Entry Well

High-frequency monitoring identifies fluid entry points, indicating thorough wellbore coverage with BroadBand Sequence service, Haynesville Shale.

-

Qualifying Diversion in Multi Clusters Horizontal Well Hydraulic Fracturing in Haynesville Shale Using Water Hammer Analysis, Step-Down Test and Microseismic Data

The objective of this study is to evaluate and maximize the effect of diversion in multi-cluster horizontal well hydraulic fracturing applications using water hammer profile analysis, step down test and microseismic monitoring.

Infill well solution workflow

Take a holistic, exploration-to-production, digital approach to eliminate challenges that impair your infill well potential.

Infill Planning

Plan to Produce

-

DrillPlan

Coherent well planning solutionProduce better-quality drilling programs in minutes.

-

Kinetix

Reservoir-centric stimulation-to-production softwareIntegrate complex reservoir and engineering data to simulate and optimize completion and fracture stimulation designs.

-

ThruBit

Through-the-bit logging servicesA comprehensive wireline suite designed for advanced lateral measurements in horizontal wells.

-

Litho Scanner

High-definition spectroscopy serviceUnlock the key elements of your reservoir—including stand-alone TOC.

-

Acoustic scanning platform

Sonic Scanner platform for downhole acoustic measurementsGain acoustic insight to anisotropy and formation geomechanics in wells at any angle.

-

Pulsar

Multifunction spectroscopy serviceAttain comprehensive formation evaluation in cased hole: one run, one tool.

Infill Design

Design to Produce

-

Petrel subsurface software

Enable discipline experts to work together and make the best possible decisions from exploration to productionEnable discipline experts to work together and make the best possible decisions from exploration to production.

-

Kinetix

Reservoir-centric stimulation-to-production softwareIntegrate complex reservoir and engineering data to simulate and optimize completion and fracture stimulation designs.

-

Intersect simulator

The Intersect™ reservoir simulator is the industry’s leading reservoir simulation technology, complete with the physics, performance, and resolution you need for every assetThe Intersect™ reservoir simulator is the industry’s leading reservoir simulation technology, complete with the physics, performance, and resolution you need for every asset

-

Delfi

Digital platformUnite planning and operations in a multidimensional environment.

Infill Construction

Drill to Produce

-

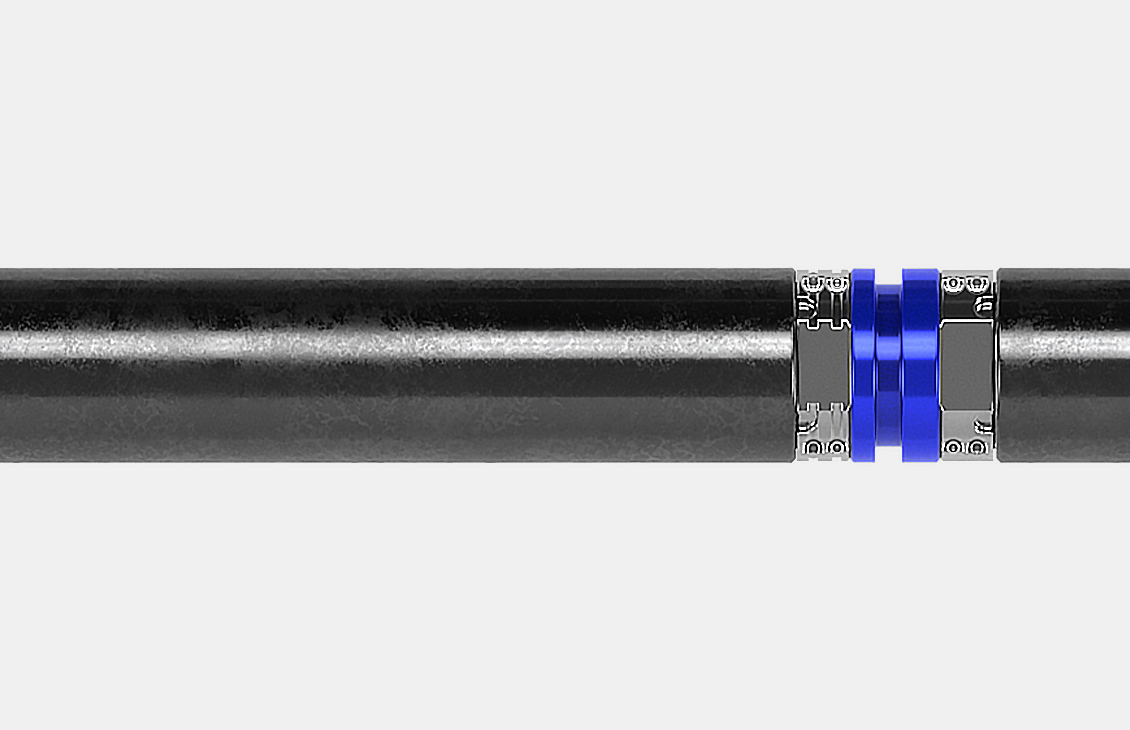

Fulcrum

Cement-conveyed frac performance technologyImprove multistage fracturing efficiency by limiting stage-to-stage communication behind the casing.

-

NeoSteer

At-bit steerable systemsNeoSteer at-bit steerable systems eliminate BHA reconfigurations between curve and lateral sections.

-

DrillOps

Intelligent well delivery and insights solutionsIntelligent well delivery and insights solutions

Infill Completion

Frac to Produce

-

Kinetix RT

Real-time stimulation optimization softwareUse surface and downhole data to facilitate immediate decisions during fracturing and acidizing operations.

-

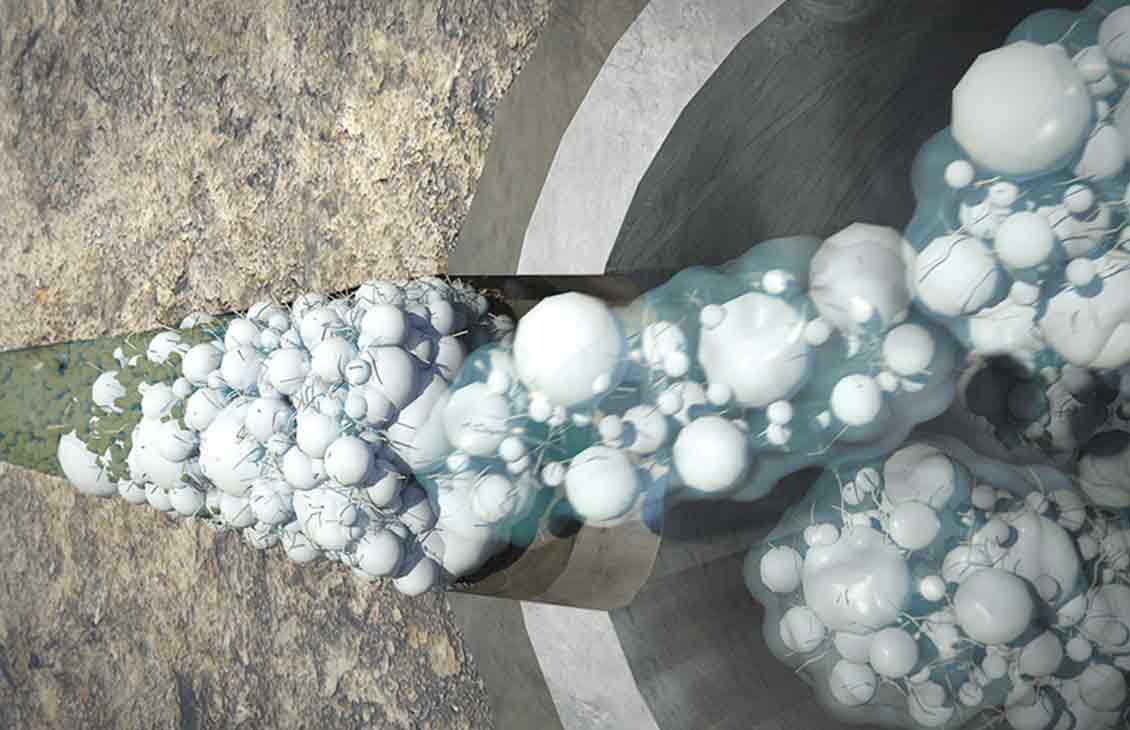

BroadBand Shield

Constrains fracture growth with far-field diversion for optimized reservoir contactConstrains fracture growth with far-field diversion for optimized reservoir contact

-

BroadBand Sequence

Fracturing serviceFracture every cluster within a limited-entry interval to maximize reservoir contact and oil and gas production.

-

WellWatcher Stim

Stimulation monitoring serviceEnhance stimulation performance and well protection through real-time downhole visibility and multiwell monitoring

Infill Production

Flow to Produce

-

Lift IQ

Production life cycle management serviceMonitor and diagnose equipment, well, and reservoir problems with a service suited for all artificial lift systems.

-

ChampionX production chemicals and services

Maximize production from reservoir to refineryImprove and assure production more safely with chemistry technologies, software, and mechanical solutions.

-

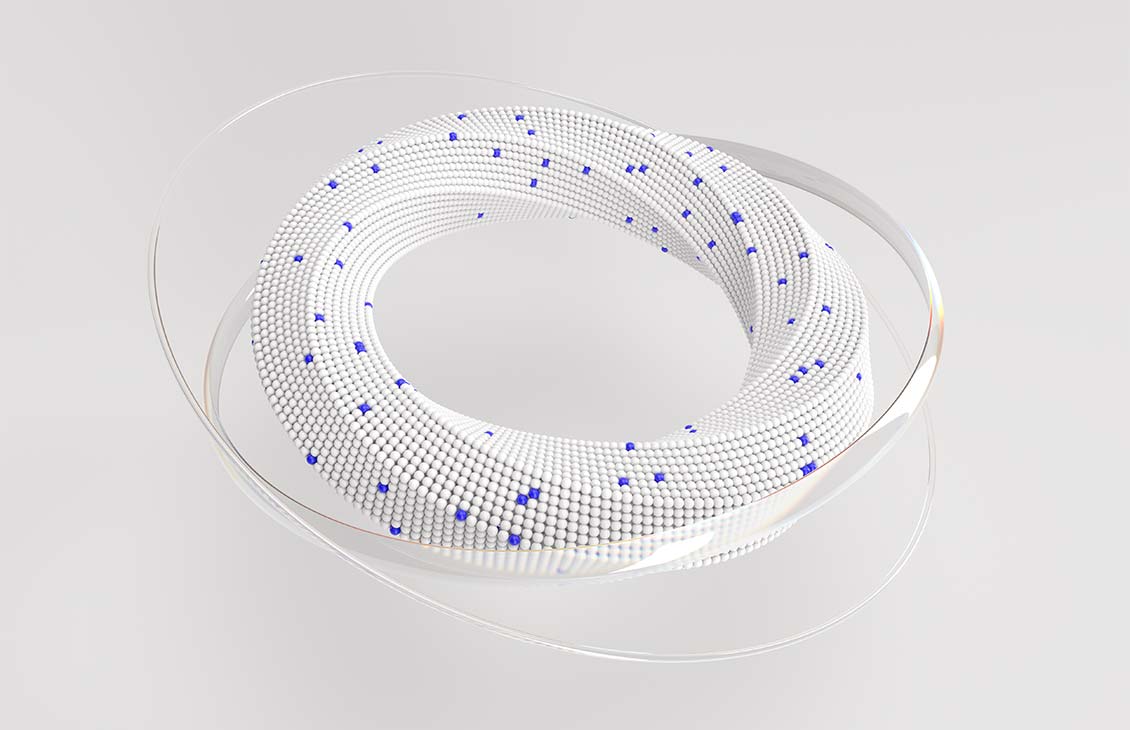

REDA Continuum

Extended-life ESP pumpImprove lift, efficiency, and reliability in challenging unconventional and conventional oil wells.

-

ChampionX production chemicals and services

Maximize production from reservoir to refineryImprove and assure production more safely with chemistry technologies, software, and mechanical solutions.

-

AvantGuard

Advanced flowback servicesOptimize productivity in fractured wells with integrated modeling, monitoring, and control.

Better Engineering Can Help You Reverse the Trend of Underperforming Infill Wells

With experience in all of the major unconventional basins in North America and around the world, our engineers can help optimize your infill well performance.

Contact Us