Valve brands

The most recognized portfolio in the industry

More than 100 years of experience

SLB is the leader in flow and pressure control technology as well as the original equipment manufacturer (OEM) of the largest number of industry-recognized valve brands. We deliver high-quality valve technologies for critical applications throughout the energy value chain—upstream, midstream, downstream—and beyond.

We design and manufacture all elements of the valve system and can address your requirements from installation through maintenance, critical spares stocking, and certification. With our 8 manufacturing and 18 aftermarket service locations worldwide, you can count on us. We built it, we back it.

Cameron

The most well-known valve brand in the industry

-

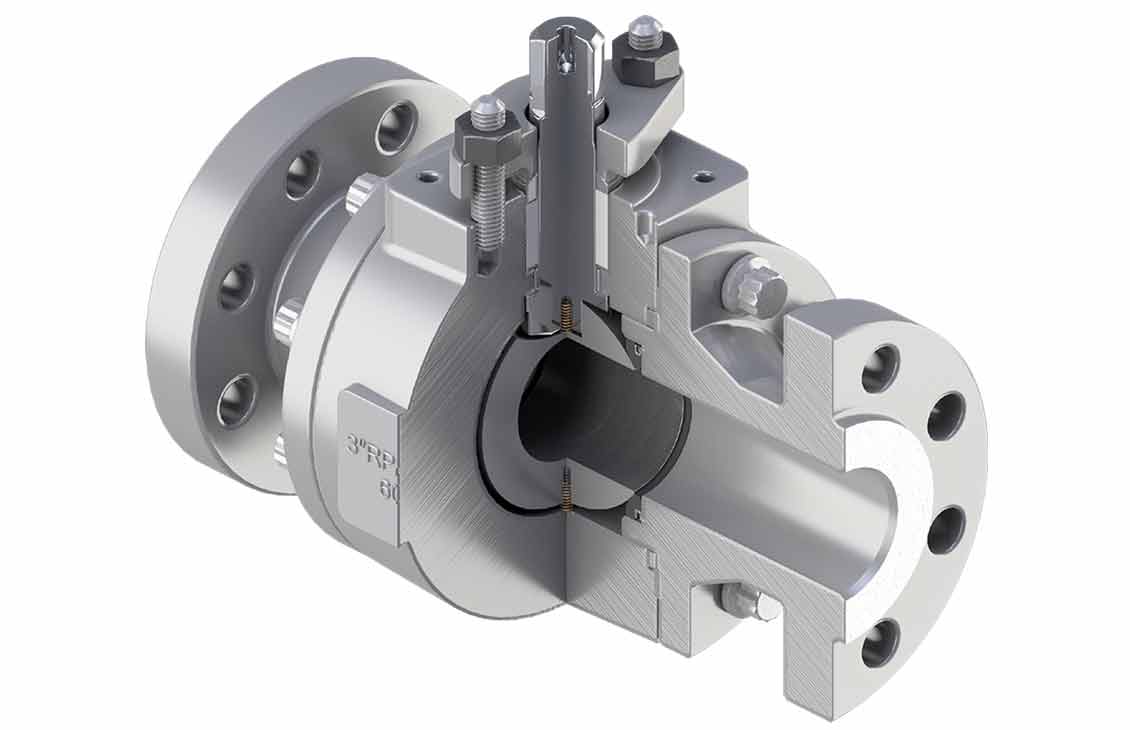

Cameron T30 Series

Fully welded ball valveLower emissions while improving uptime and profitability.

-

Chemical Injection Metering Valves

Remotely operated, ROV-retrievable, self-regulating subsea CIMVsRedefine achievable accuracy with nonintrusive line-of-sight ultrasonic flowmetering.

-

Nonretrievable Chokes

800 installed to dateMount to a subsea structure or incorporate into retrievable FCM or choke bridge.

-

Subsea Choke Actuators

High performance for every purposeReduce erosion problems and ensure positive flow.

Demco

Butterfly and gate valves

-

Demco

Butterfly valvesDurable, lightweight, and ideal for a wide range of applications where space is at a premium.

-

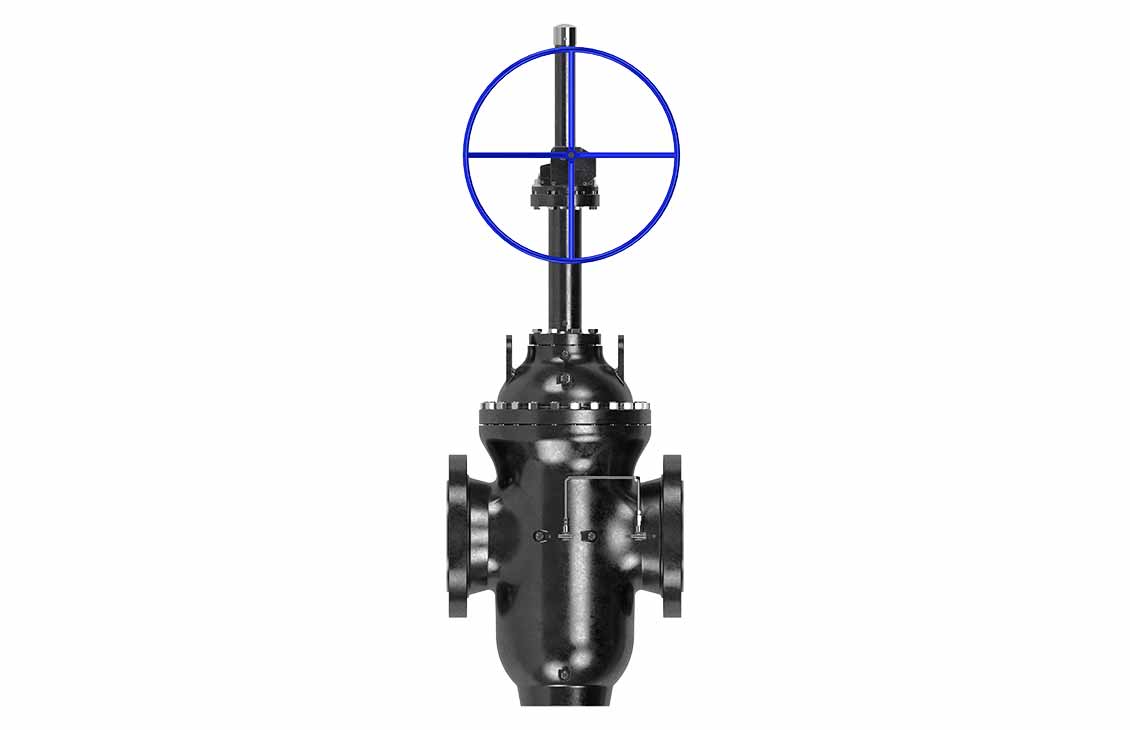

Series DM Demco

Gate valvesPremier gate valves providing reliable performance and extended service life in abrasive drilling applications.

-

DEMCO DT and DB

Gate ValvesOptimize operations in corrosive CO2 injection and waterflood applications.

Dynatorque

Gear operators

-

DYNATORQUE BG

Multiturn bevel-gear operator20 different frame and spur combinations.

-

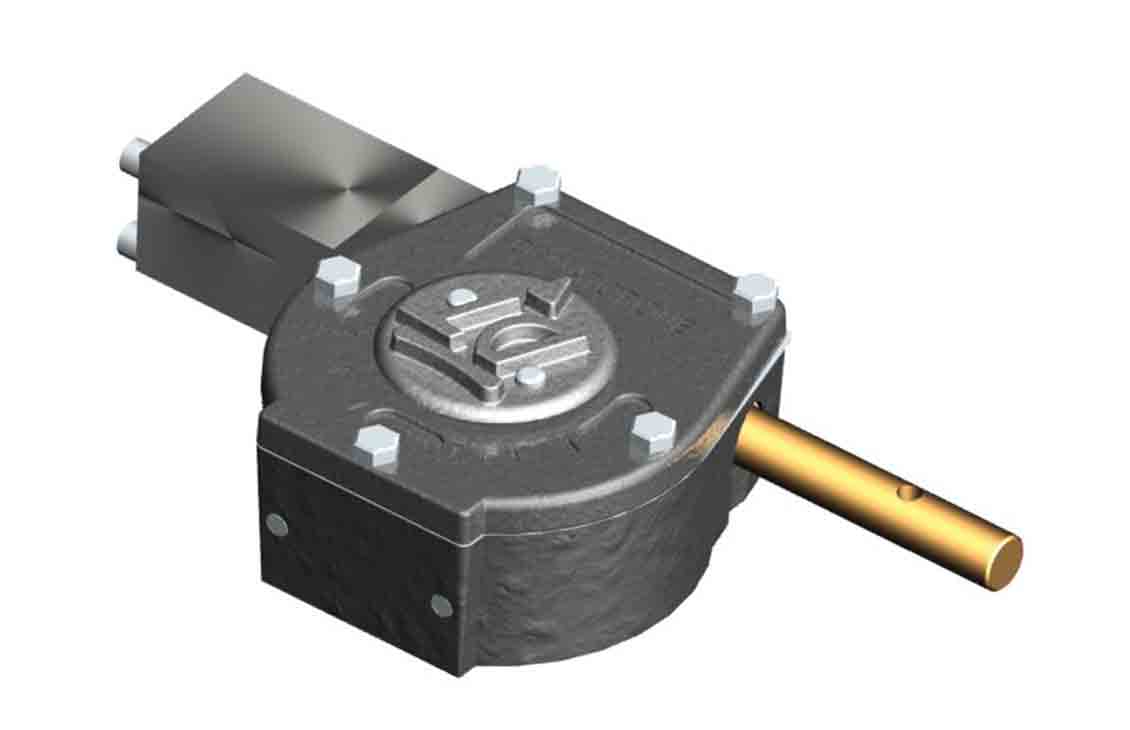

Dynatorque DT

Quarter-turn severe-service gear operatorSuitable for any application that requires valve operation.

-

DYNATORQUE 360

Multiturn worm-gear operatorCommercial-grade, worm-geared, and made for multiple output turns.

-

AWWA-Grade DYNATORQUE 90

Quarter-turn worm-gear operatorMeet AWWA Spec C504.

-

Commercial Aluminum DYNATORQUE 90

Quarter-turn worm-gear operatorsAluminum standard housing material.

-

Memory-Stop Device

DYNATORQUE accessoryFor when valves or dampers must be opened/closed to same position.

-

Industrial DYNATORQUE 90

Quarter-turn worm-gear operatorMeet marine, submerged, and high- and low-temperature requirements.

-

Stainless Steel DYNATORQUE 90

Quarter-turn worm-gear operators300 series stainless steel unit housings, covers, indicators, and more.

-

Dynatorque D-Lock

Valve-locking deviceFor automated valves (pneumatic, hydraulic, or electric) requiring lockout capability to prevent valve rotation.

-

Dynatorque D-Stop

Partial-stroke test deviceUsed on emergency shutdown valves while they flow process fluids and full-stroke valve testing isn’t practical.

-

DT, SRD, and BG Locking Devices

For quarter-turn, multiturn, and bevel-gear operatorsAvoid inadvertent handwheel rotation.

-

SD Locking Device

For manual overridesAvoid inadvertent handwheel rotation.

-

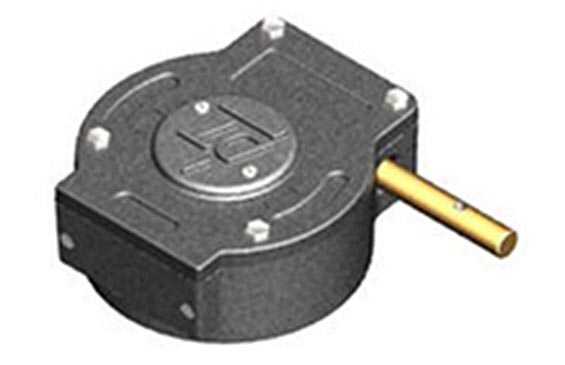

Dynatorque SD

Declutchable manual overrideEnables manual operation of an automated valve (pneumatic, hydraulic, or electric) in a contingency.

-

Dynatorque SRD

Nondeclutchable manual overrideEnables manual operation of an automated valve (pneumatic, hydraulic, or electric) in a contingency.

-

Spur & Miter Gears

Part of our family of Dynatorque™ valve accessoriesUsed where a nonself-locking mechanical advantage or change in input drive orientation is required.

-

Handwheels

Suited for Cameron products6- to 48-in sizes, many in recessed or flat versions.

Grove

Valves

-

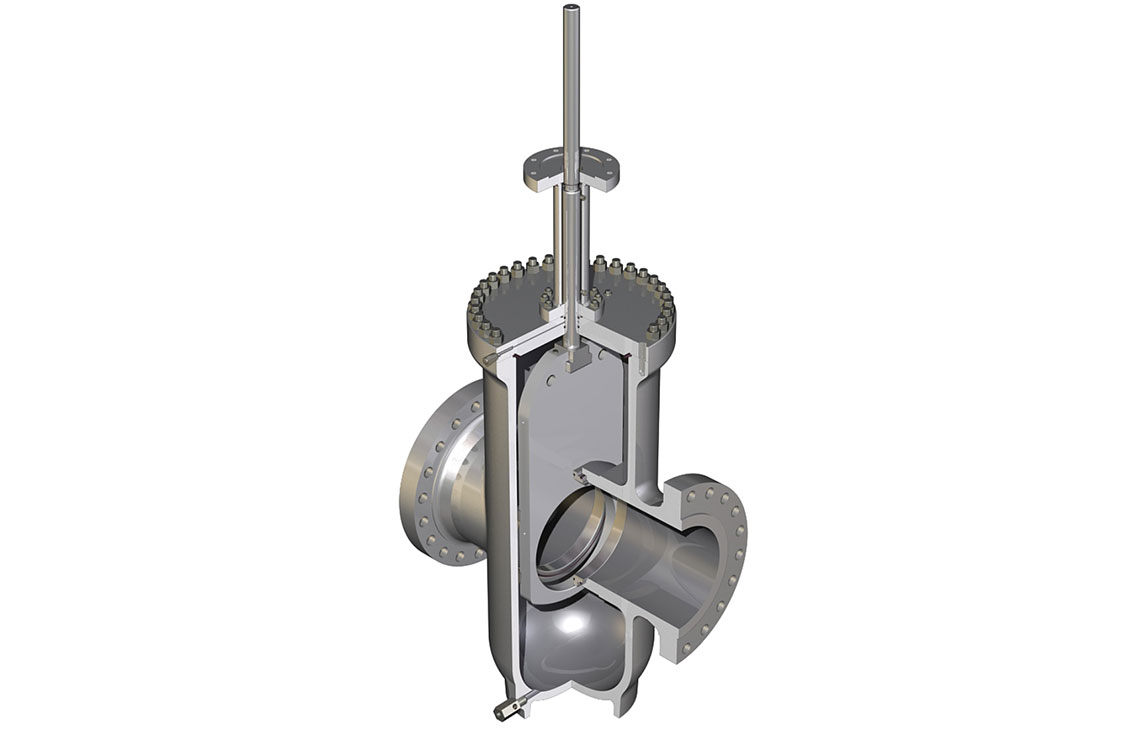

Grove G7

Fabricated gate valveAPI Spec 6D–compliant valve with a through-conduit design that promotes long-term, reliable sealing performance.

-

Grove G12

ValveThrough-conduit gate valve with a cast body, fully compliant with API Spec 6D.

-

Grove B4

Trunnion-mounted, side-entry ball valve2- to 4-in sizes, ANSI 150 to 1500.

-

Grove B5

Trunnion-mounted, side-entry ball valveSizes: 6–64+ in; Classes: ANSI 150–1500

-

Grove B7

Side-entry ball valve1 1/2- to 20-in sizes, ANSI 2500.

-

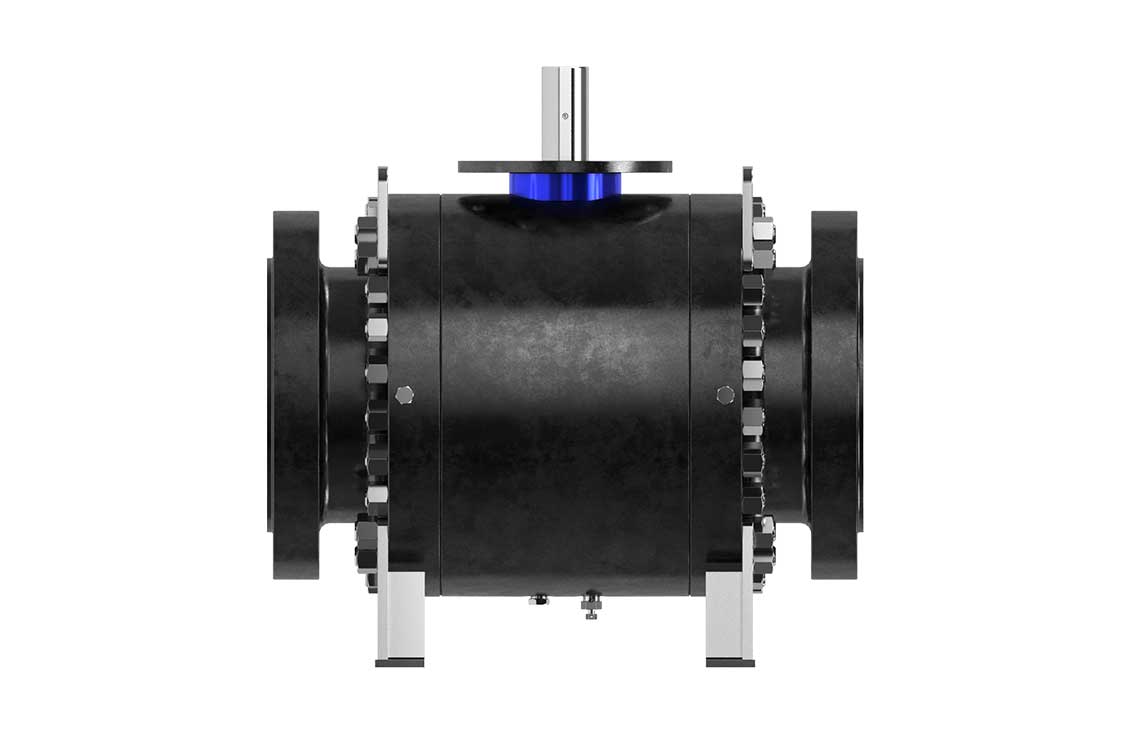

Grove B8

Fully welded ball valve2- to 60-in sizes, ANSI 150 to 2500.

-

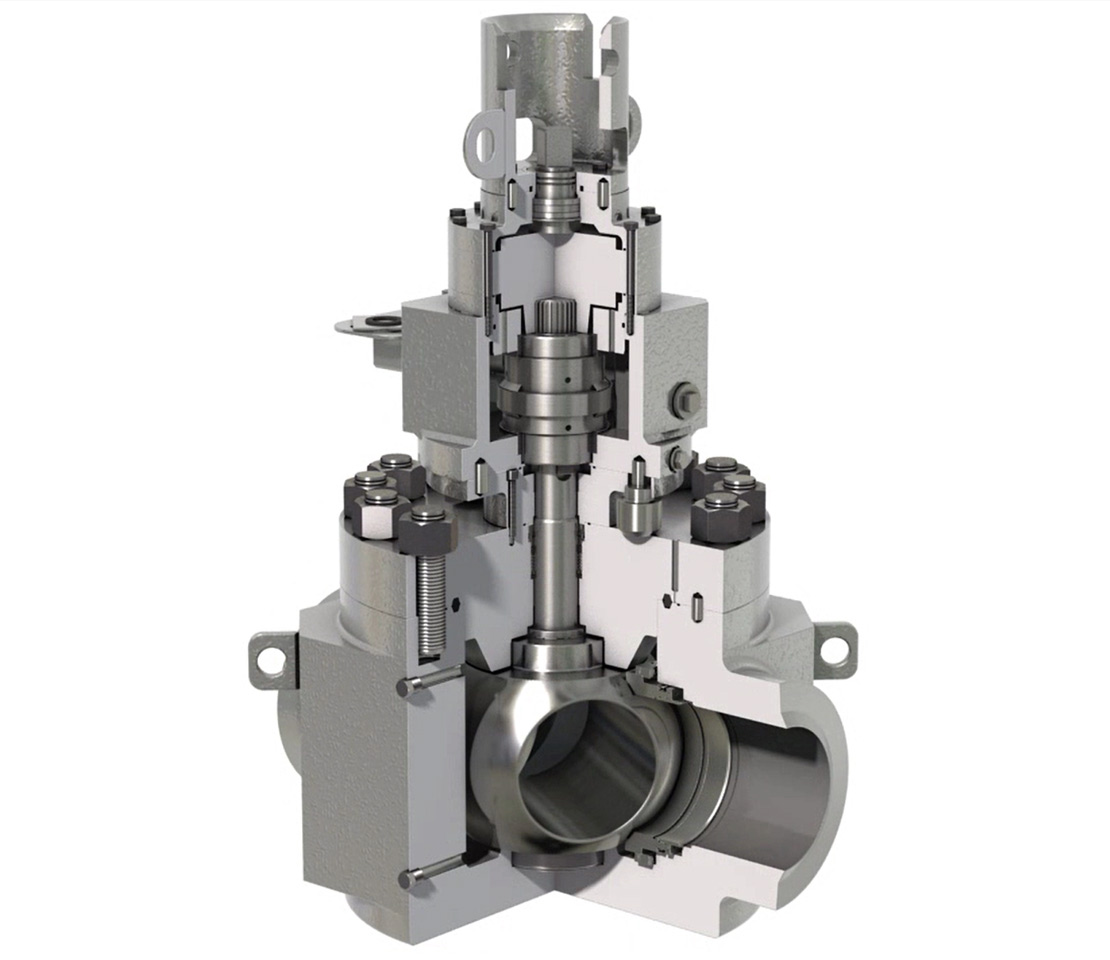

Grove BT1

Top-entry ball valve1/2- to 12-in sizes, ANSI 150 to 1500.

-

Grove BT2

Top-entry ball valve1 1/2- to 60-in sizes, ANSI 150 to 2500.

-

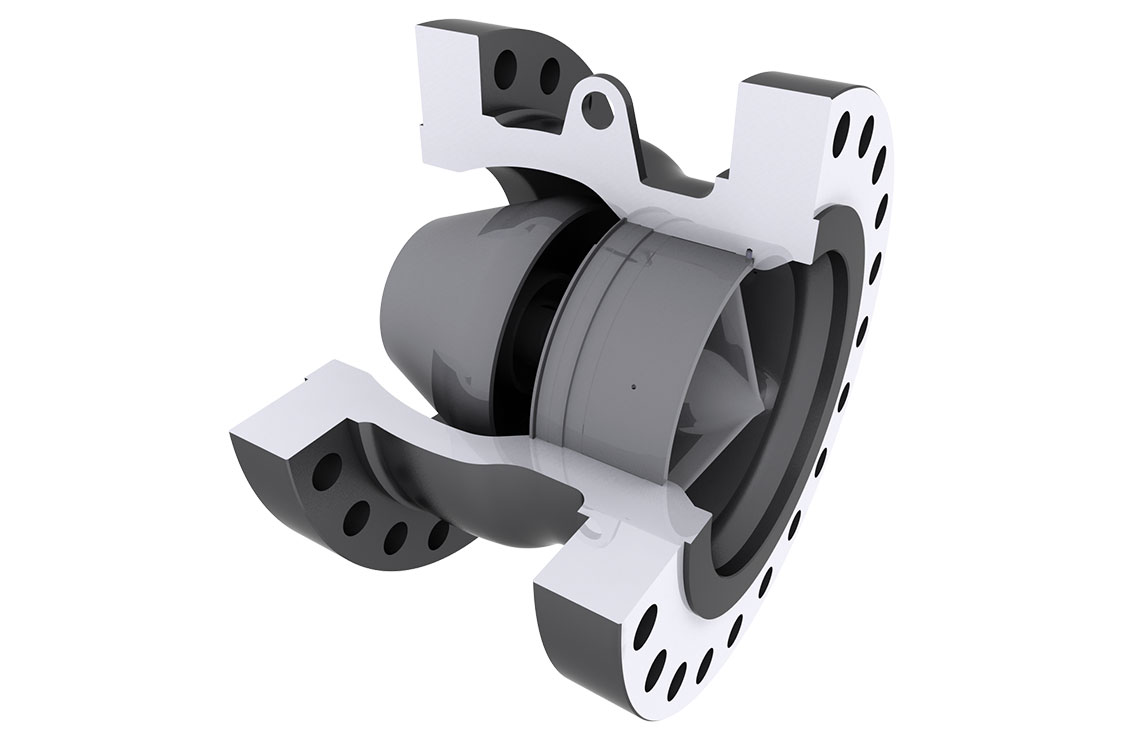

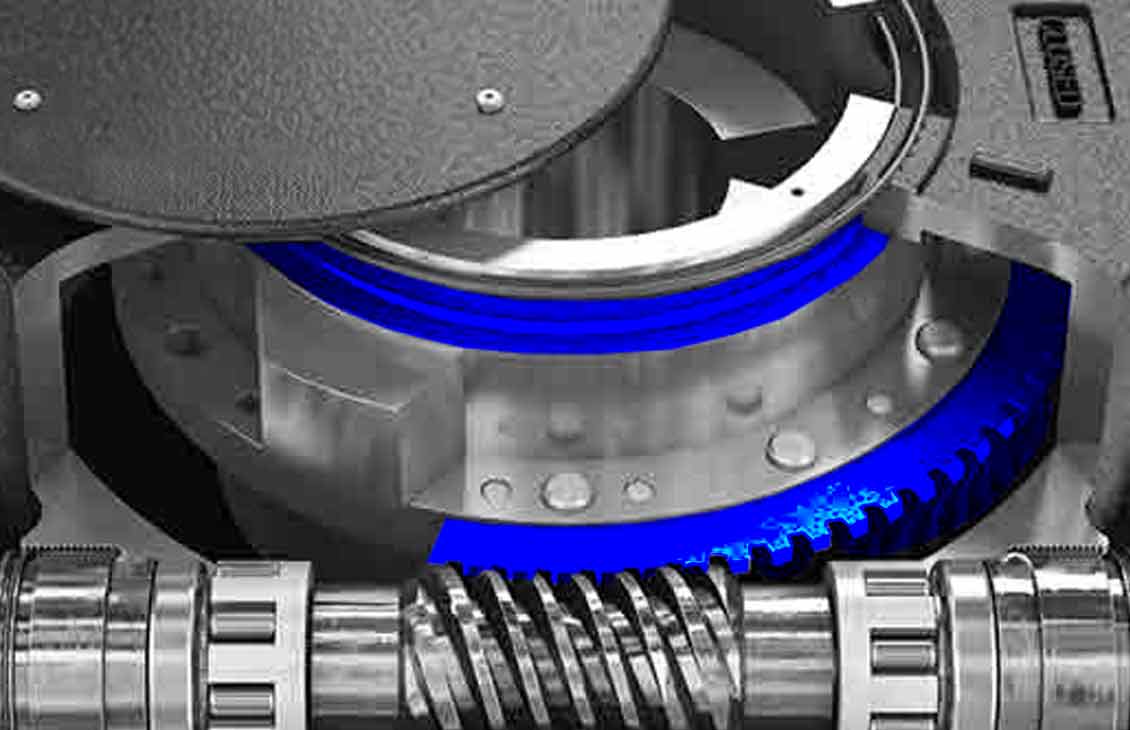

Grove IST

Integrated seat technology ball valveOvercome ball flexing to 10,000 psi.

Ledeen

Actuators

-

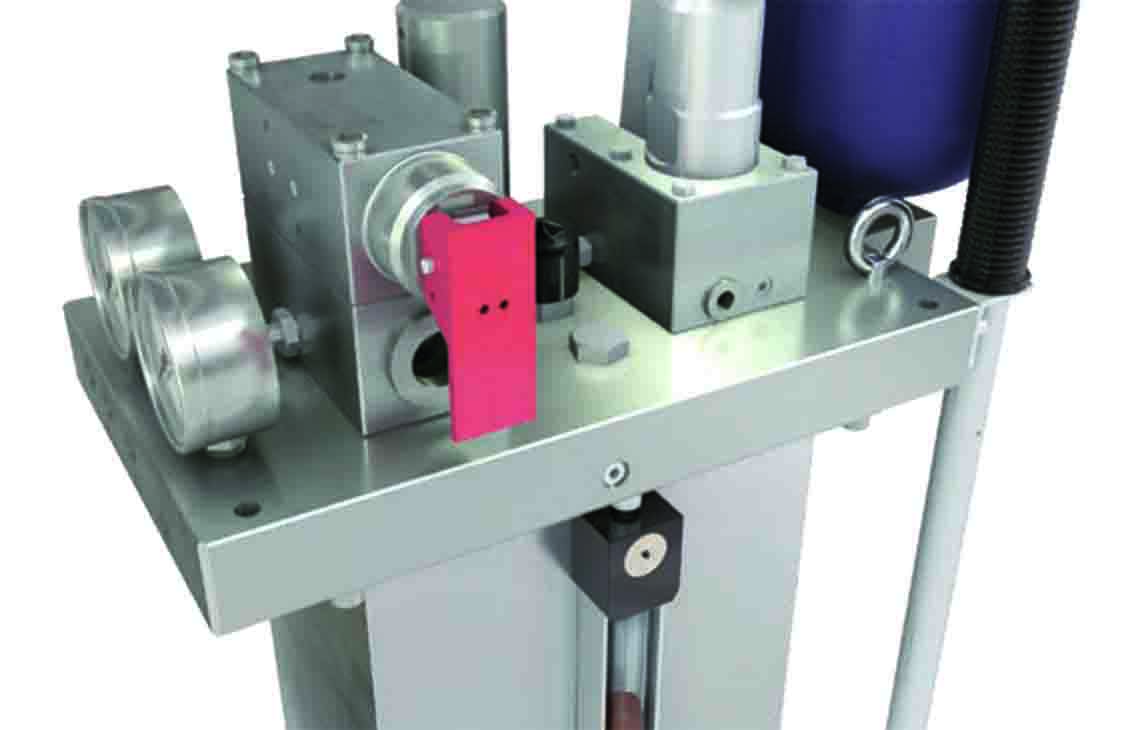

Compact Ledeen Actuators

Customer-focused solutionsSave valuable space with one of the smallest compact actuators on the market.

-

Ledeen SCCS

Self-contained control systemEnsure reliable valve shutdown when an external powersource is unavailable.

-

Direct-Gas Ledeen Actuators

Efficient modular assemblyAchieve on-off control of ball or plug valves.

-

Gas-Over-Oil Ledeen Actuators

Quarter-turn operationEnhance flexibility with consistent engineering and modular design.

-

Hydraulic Ledeen Actuators

Quarter-turn operationAchieve on-off modulating control of multiple valve types.

-

Pneumatic Ledeen Actuators

Quarter-turn operationReliable performance with compressed air, natural gas, or nitrogen.

-

Subsea Ledeen Actuators

Control and actuation of subsea valvesChoose from double-acting or spring-return designs for shallow or deep water.

Maxtorque

High-performance gear operators

-

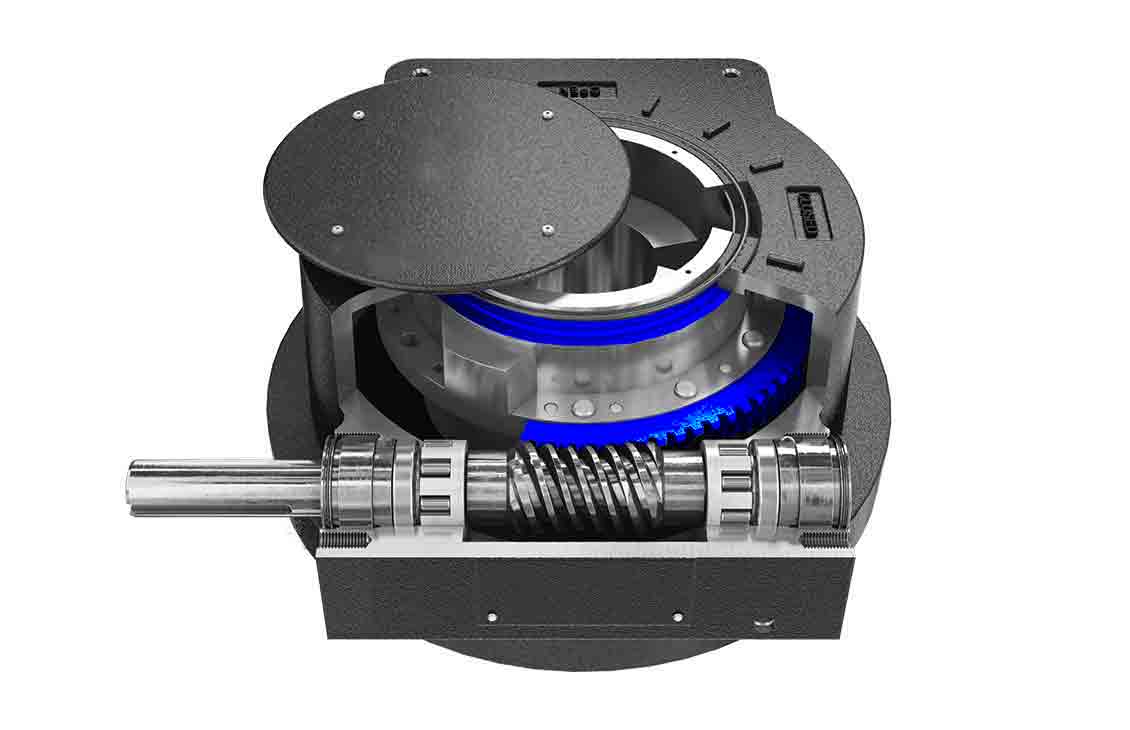

Maxtorque

High-performance worm gearsWorm-gear solutions that minimize effort.

-

Declutchable and Manual Overrides

Save space and increase uptimeRequiring reduced number of turns, rim pull, and handwheel size for manual operation of automated valves.

-

Rising Stem Applications

High-ratio, small-envelope, robustSee our MAXTORQUE products for rising stem applications.

-

Severe-Service Applications

For saltwater, steam, and corrosive environmentsReduce turns to close and rim pull by 75% in critical environments.

-

Subsea Gear Operators

Active and passive pressure compensationWithstand high pressures at deepwater depths with Maxtorque subsea worm gears.

-

Temperature Compensators

Extend valve life by reducing wear and damage to the actuator and gearFor a wide range of SLB and third-party valves.

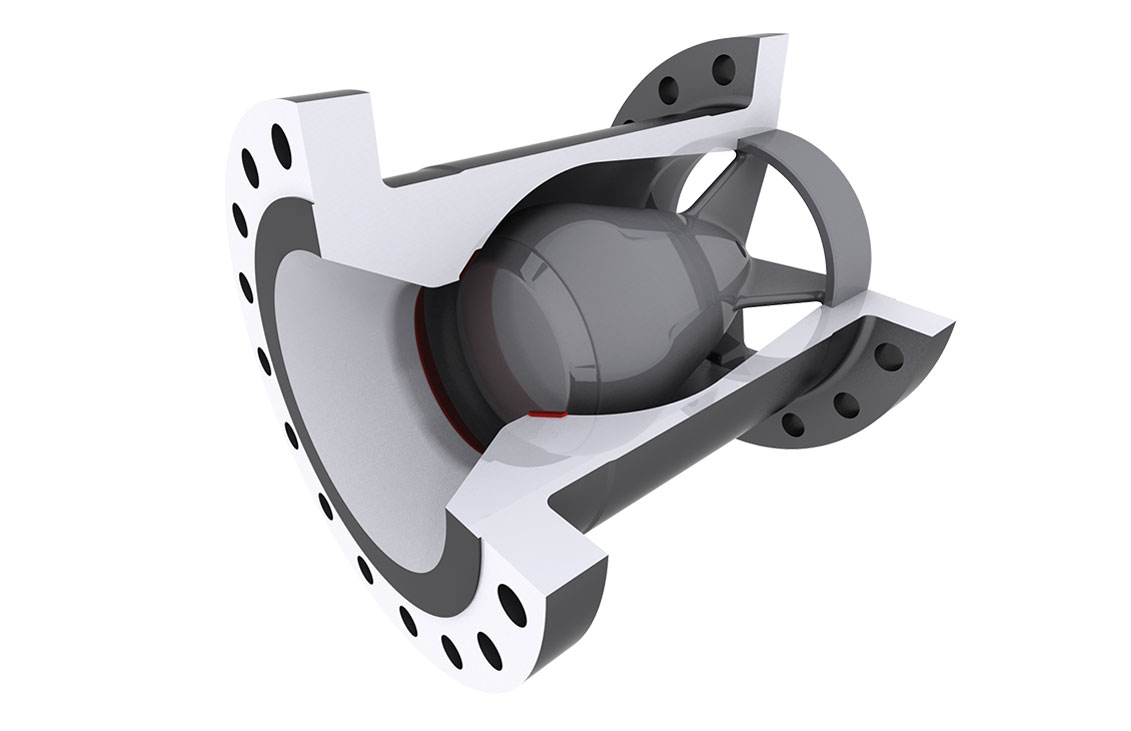

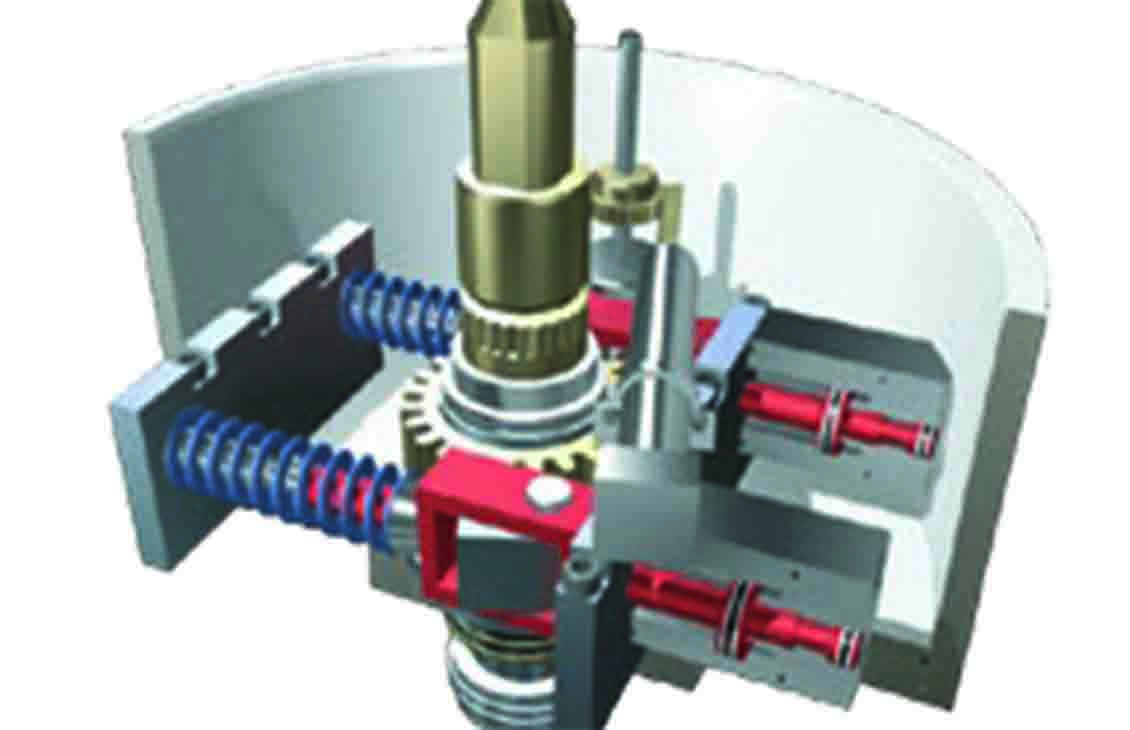

Orbit

Rising stem ball valve

Tom Wheatley

Check valves

-

Tom Wheatley Piston Check Valve

API Spec 6D–compliant valve, especially effective in scenarios with pressure surges and pulsating flowNonslam, reliable operation that stands up to excessive wear.

-

Tom Wheatley Swing Check Valve

API Spec 6D–compliant, fullbore pipeline check valve for demanding environmentsField-proven backflow prevention.

WKM

Valves

-

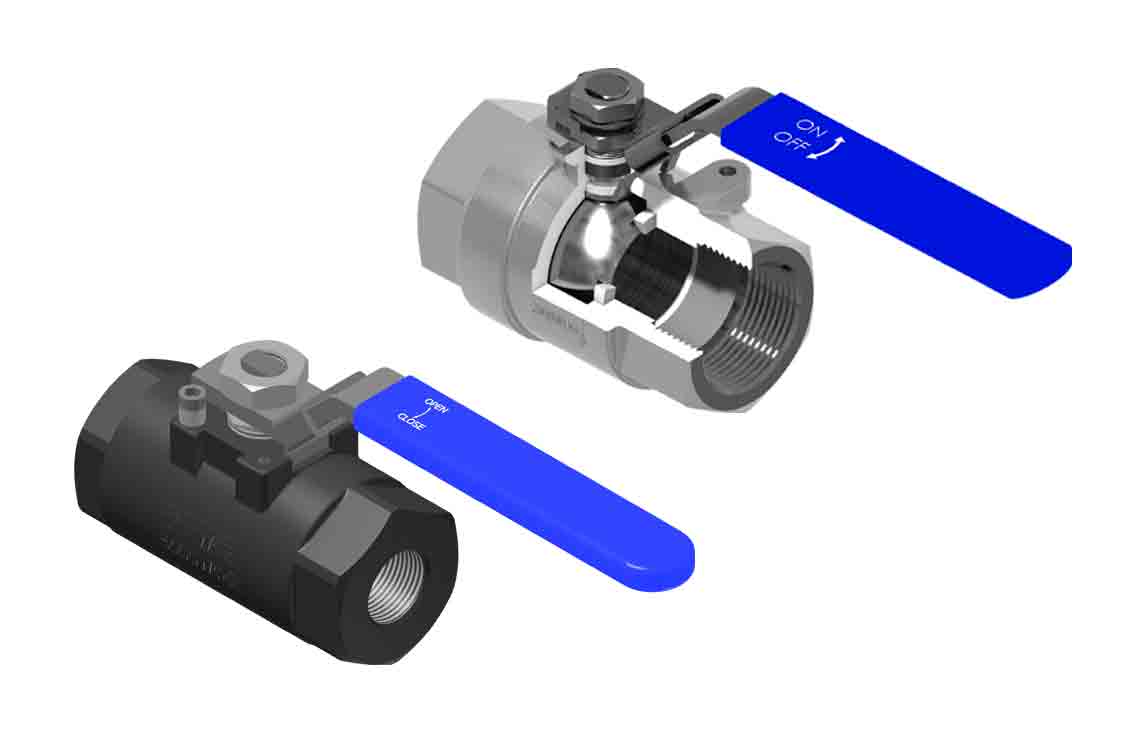

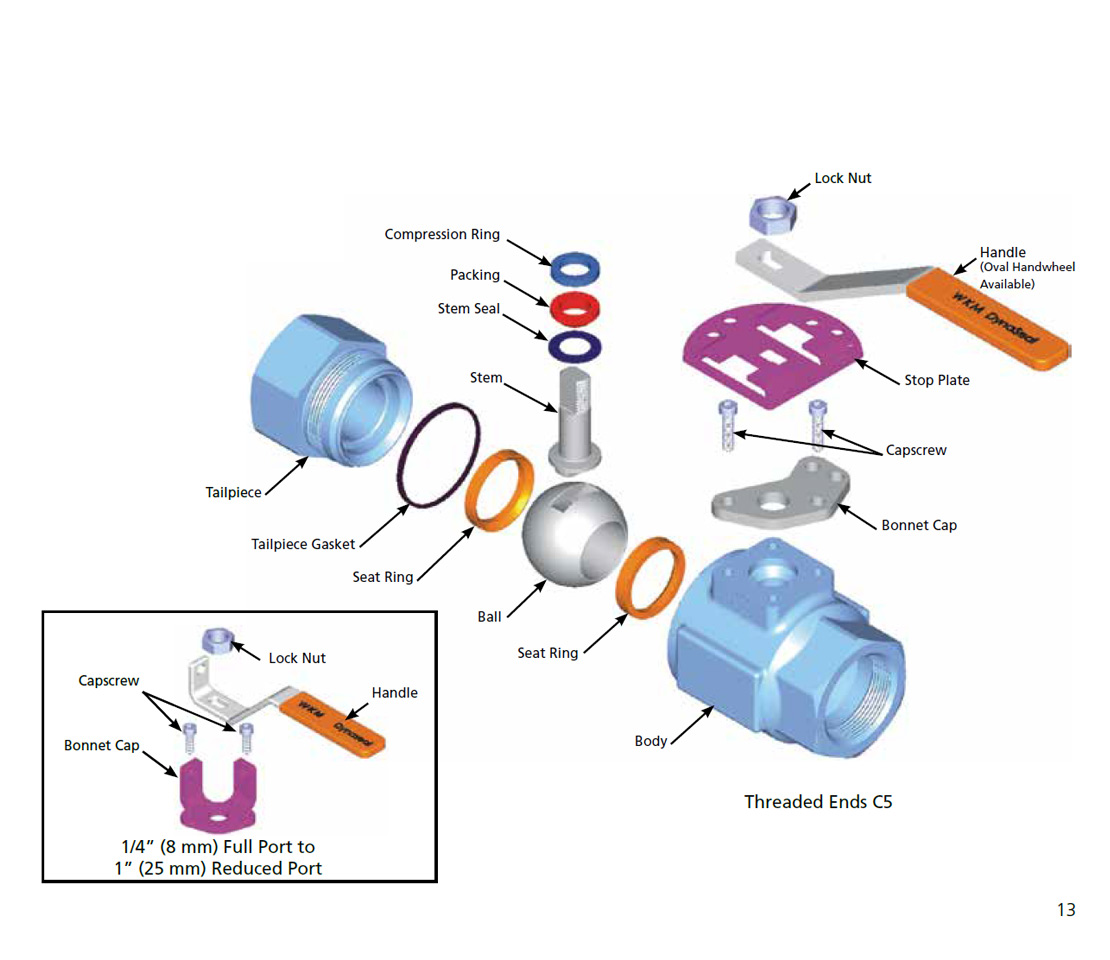

WKM 310C5

Floating ball valveProven performance in a wide range of oilfield, chemical, petrochemical, and hydrocarbon processing applications.

-

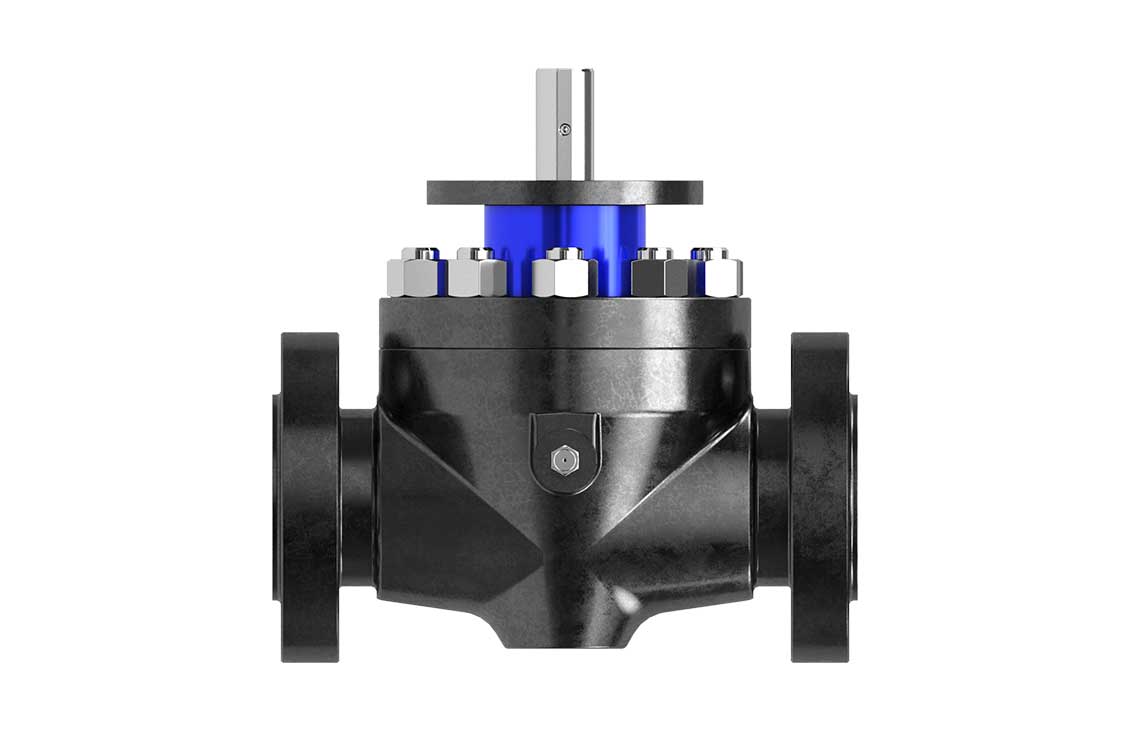

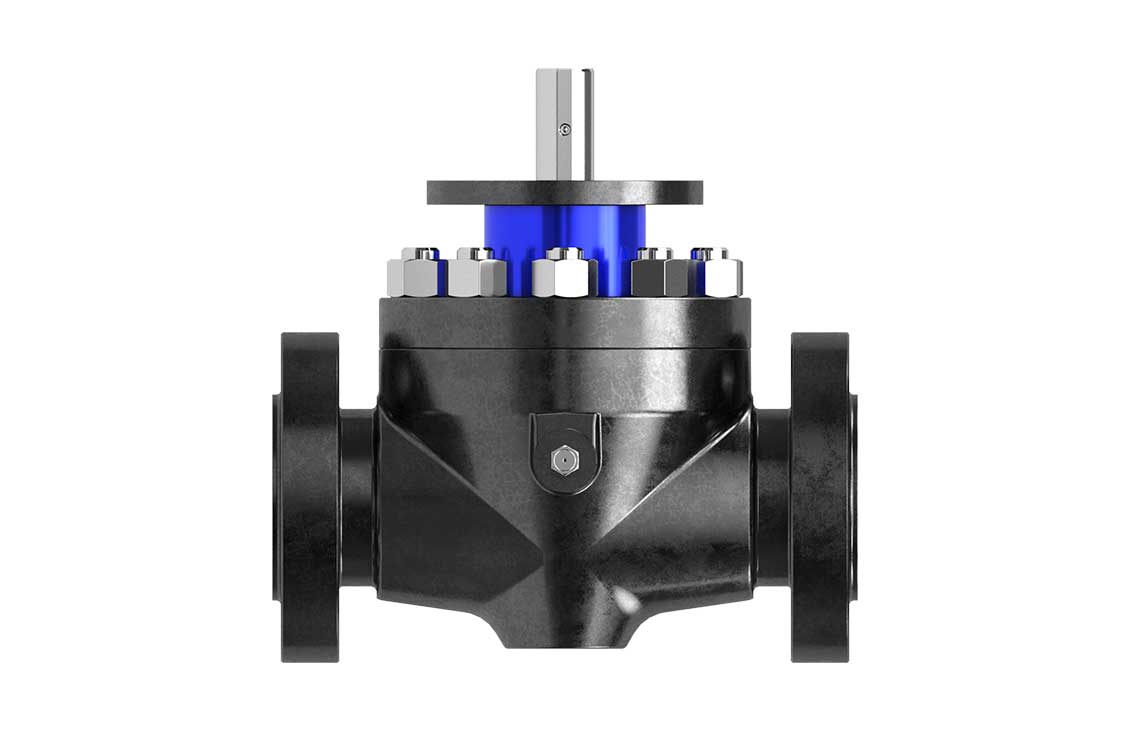

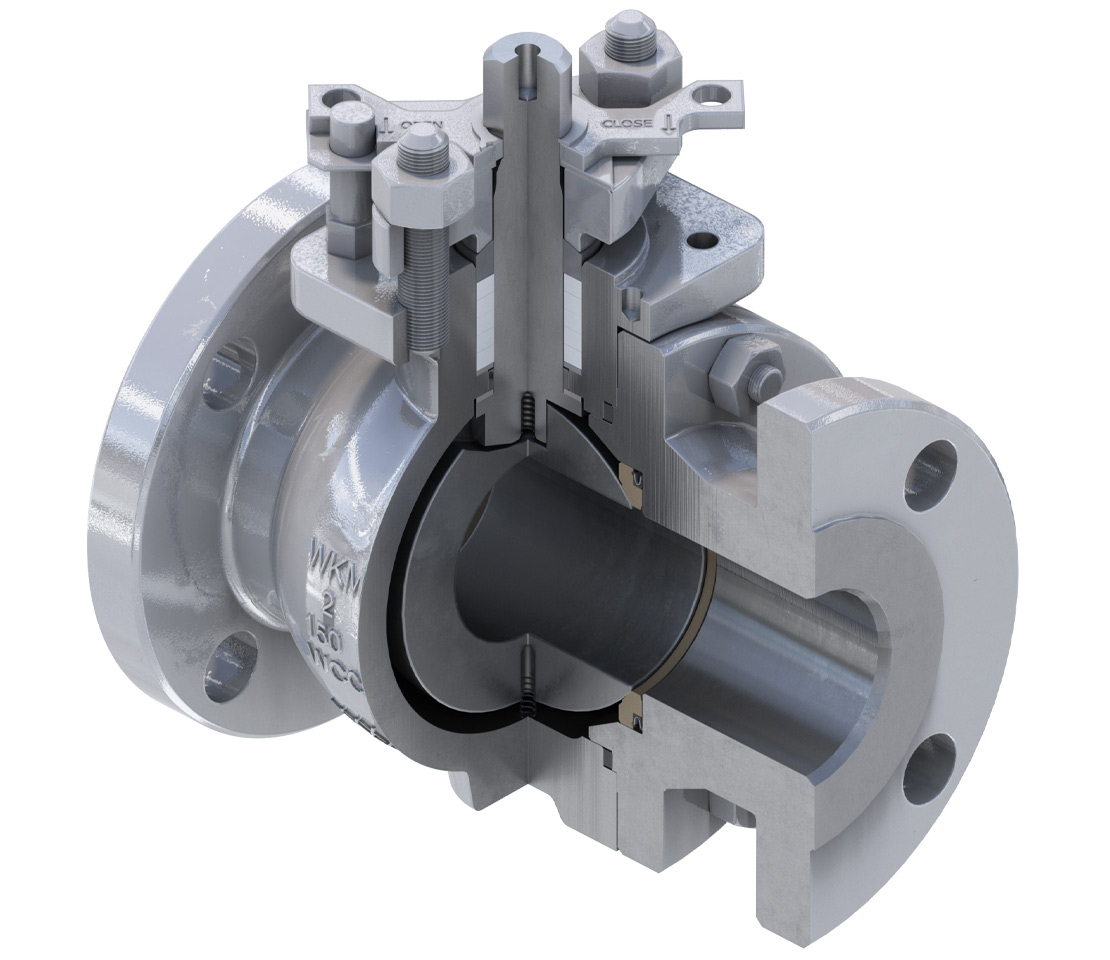

WKM 320F

Flanged floating ball valvesEngineered for heavy-duty, maintenance-free performance in a range of applications across multiple industries.

-

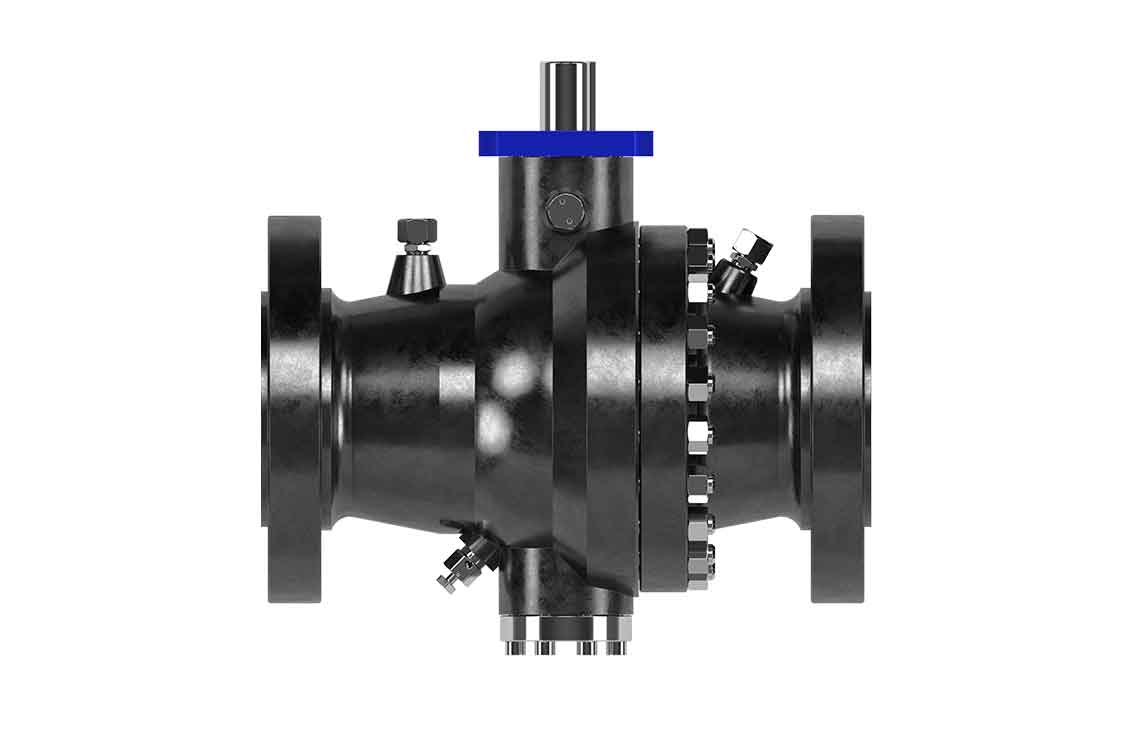

WKM 370D Series

Trunnion-mounted ball valvesVariety of ANSI and API Spec 6D designs.

-

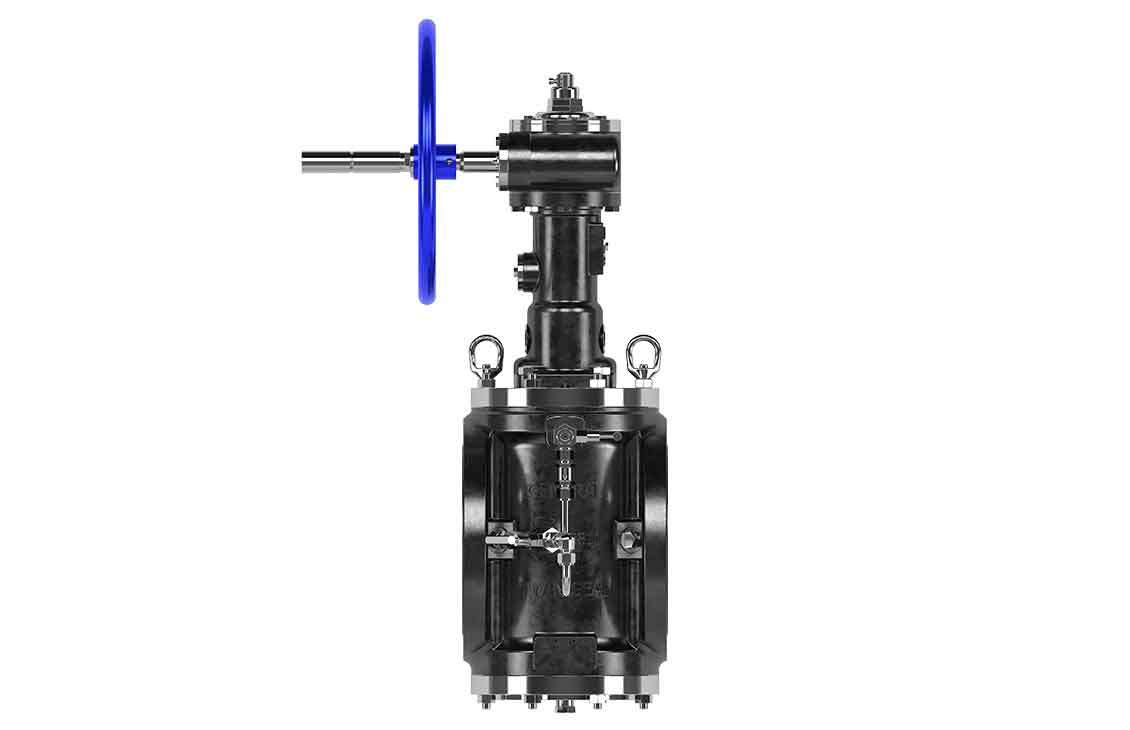

WKM Pow-R-Seal

Double expanding gate valveEnhanced safety and seal reliability.

-

WKM Saf-T-Seal

Slab gate valveSimple yet rugged and reliable through-conduit valve.

-

M-HT

API Spec 6A expanding gate valveWithstand temperatures up to 650 degF [343 degC].

-

WKM High-Performance Butterfly Valves

Double-offset butterfly valvesSealing performance of a ball or gate valve but in a much smaller profile.